Textile towel fabric

A fabric and towel technology, applied in the field of textile fabrics, can solve the problems of inability to meet the requirements of anti-mildew, antibacterial, moisture absorption and ventilation, inability to meet consumer demand, poor anti-ultraviolet and antibacterial functions, etc. Soft and flowing, full and thick look

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

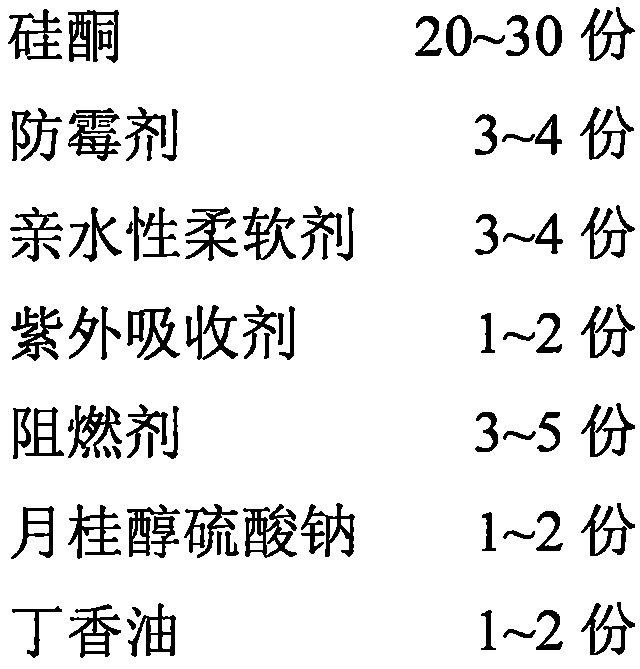

Method used

Image

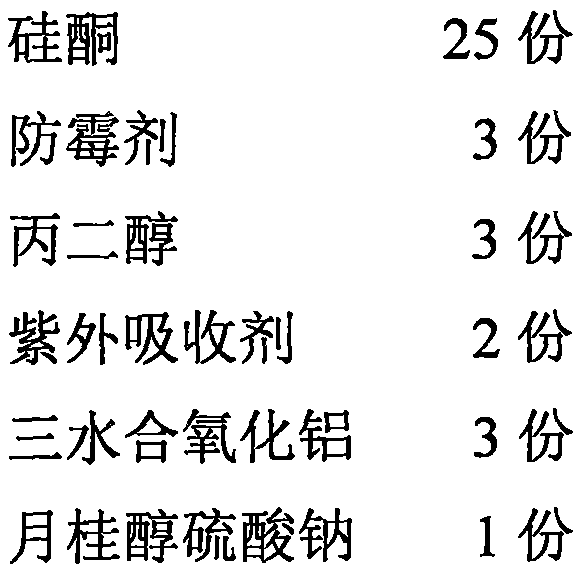

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0018] In this embodiment, the textile fabric includes an upper fabric, a lower fabric and a middle fabric layer. The upper fabric and the lower fabric have the same structure, and both include warp yarns and weft yarns. The warp yarns are blended with 80% cotton fibers and polyester during weaving to form Blended yarn with a linear density of 20-25tex. The weft yarn is a blended yarn with a linear density of 17-20 tex made by blending hemp fiber, abaca fiber and cotton fiber in a ratio of 26:4:70. The average width of the gaps between the warp yarns is greater than 100 μm, and the average width of the gaps between the weft yarns is greater than 80 μm.

[0019] Then the upper fabric and the lower fabric are processed separately to form a two-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com