Environmental-protective and regenerative solid wooden plastic door and window and its production

A production method and an environmentally friendly technology, which are applied in the direction of the wing fan frame, etc., to achieve the effects of improving thermal insulation performance, reducing solid waste pollution and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

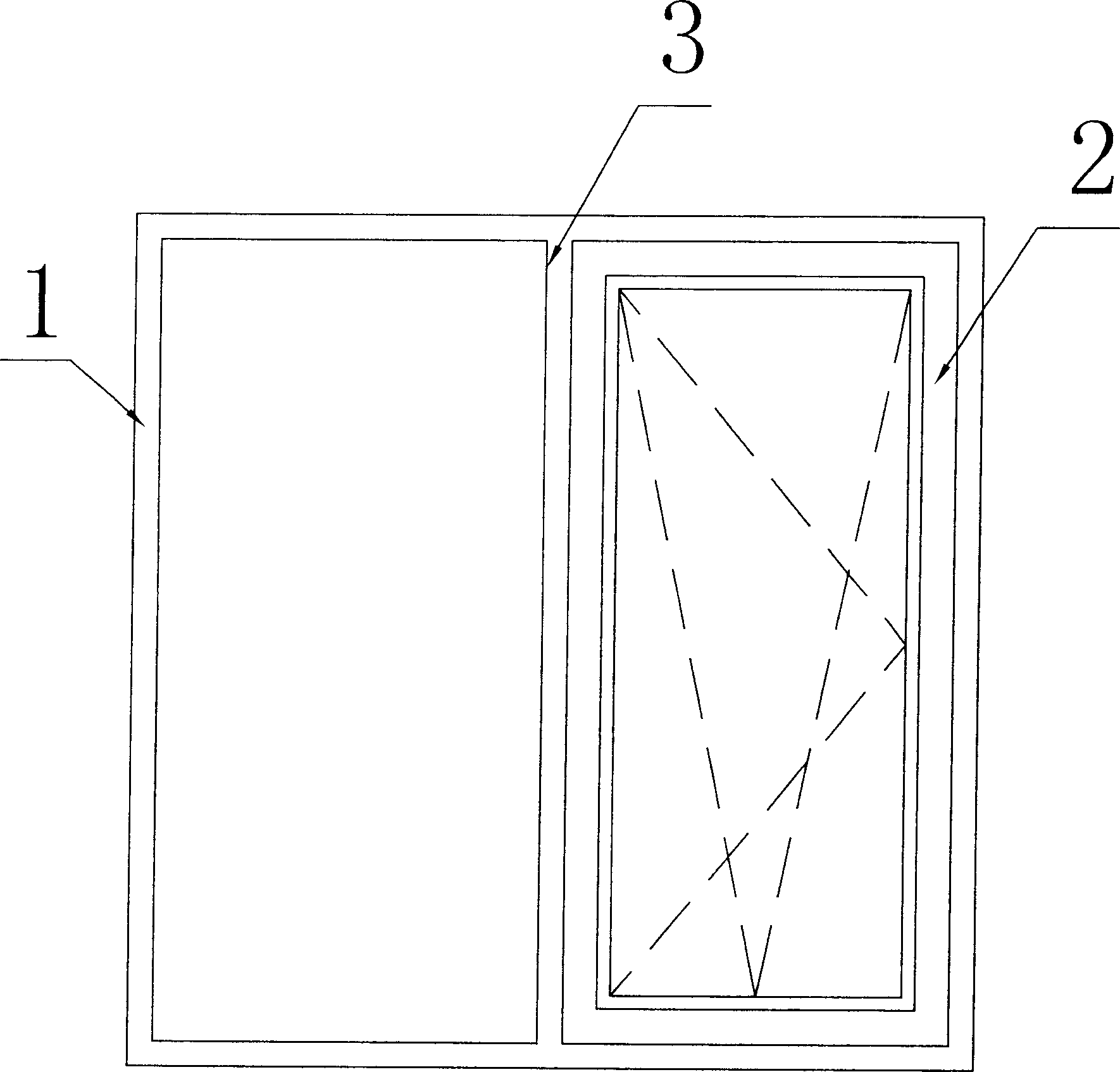

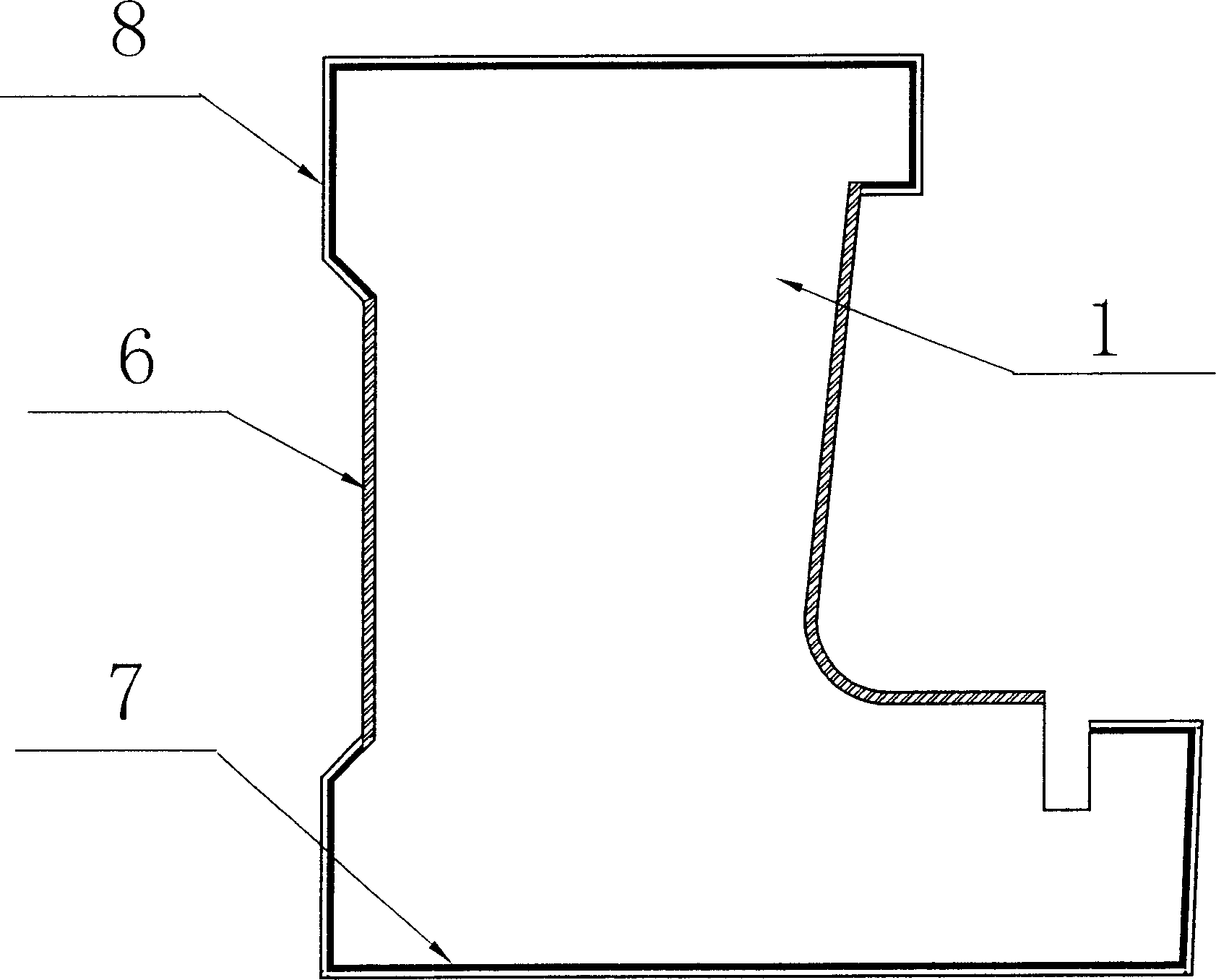

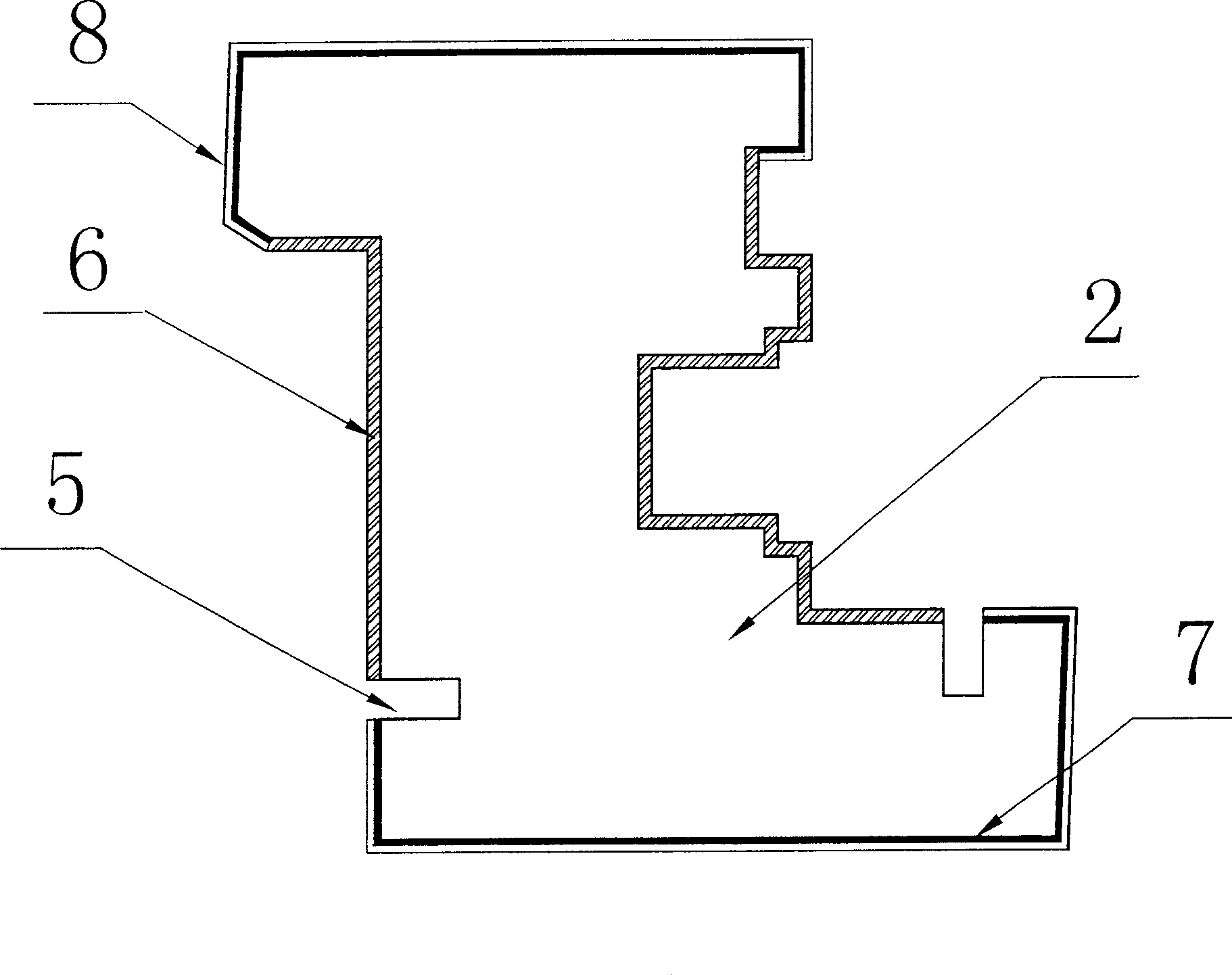

[0029] see example Figure 1-4 : The renewable environment-friendly solid-core wood-plastic doors and windows of the present invention, whose profiles are solid core profiles, are composed of frame profiles 1, fan profiles 2, stile profiles 3 and sealing strips 4 to form doors and windows, and fan profiles 2 are provided with glass The bead groove 5, the side surfaces of the above-mentioned frame profiles 1, fan profiles 2, and stile profiles 3 are coated with a plastic layer 6, and the exposed surfaces of the above-mentioned frame profiles 1, fan profiles 2, and stile profiles 3 facing indoors and outdoors are covered by an adhesive layer 7. Aluminized layer 8 is adhered.

[0030] The weight ratio of the main raw materials of the above solid core profiles:

[0031] The recycled polyolefin resin adopts polypropylene or polyethylene: the addition amount is any value between 40% and 70%;

[0032] The plant fiber filler adopts sawwood powder, hemp powder, bamboo powder, straw p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com