Manufacture technology of hemp woven fabric reinforced composite material sheet

A composite material and fabric reinforcement technology, applied to flat products, applications, household appliances, etc., can solve the problems of undesignable strength in all directions, failure to meet the use requirements, multi-surface treatment work, etc., to achieve enhanced designability and manufacturing costs The effect of low and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

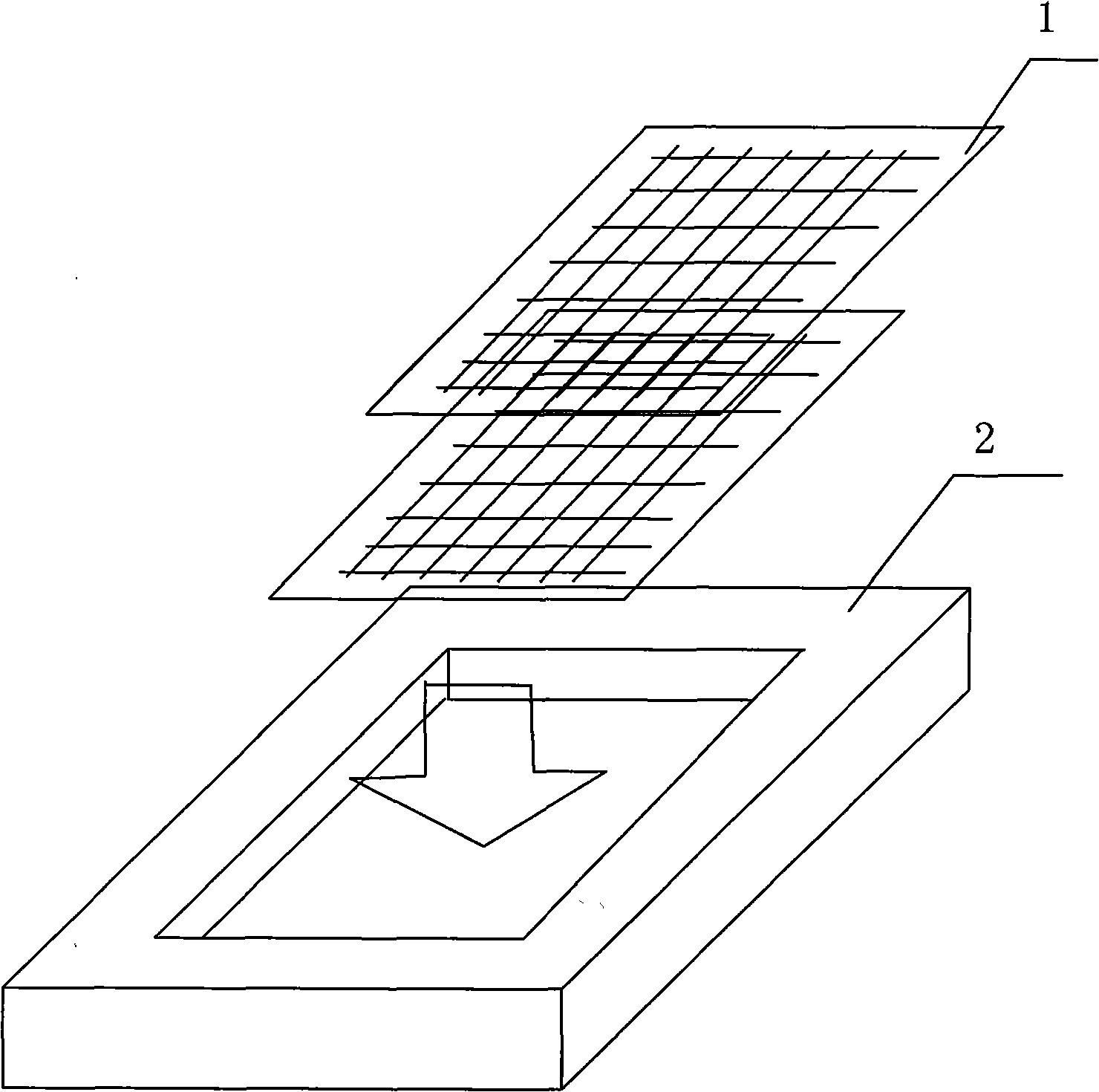

[0010] see figure 1 , the linen woven fabric 1 is laid layer by layer in the prefabricated mold 2 in an orderly manner according to the designed layer angle and number of layers, and each layer of linen woven fabric is cross-laminated. Generally, the number of layers of linen woven fabric is 4 layers to 12 layers, 8 layers of flax woven fabrics are laid in this embodiment, and the laying angles of each layer of flax woven fabrics from the beginning to the end are successively 0°, 90°, +30°, -30°, +30°, -30°, 0°, 90°. The volume content of flax fiber is not less than 40%, then the mold is closed and sealed, and the mold is filled by using the closed mold molding process-resin transfer molding (RTM process). The mold filling adopts high-pressure injection at one end, and the filling resin uses Epoxy resin and add corresponding diluent and curing agent to adjust resin viscosity and curing time. The ratio of resin curing system is: epoxy resin, polyamide curing agent, reactive di...

Embodiment 2

[0012] see figure 1 , the jute woven fabric 1 is laid layer by layer in the prefabricated mold 2 in an orderly manner according to the designed laying angle and the number of layers, and each layer of jute woven fabric is cross-laminated. Generally, the number of layers of the jute woven fabric is 4 layers to 12 layers, 8 layers of jute woven fabrics are laid in the present embodiment, and the laying angles of each layer of jute woven fabrics from the beginning to the end are successively 0 °, 90 °, +30 °, -30 °, +30 °, -30°, 0°, 90°. The volume content of jute fiber is not less than 40%, then the mold is closed and sealed, and the mold is filled by using the closed mold molding process-resin transfer molding (RTM process). The mold filling adopts high-pressure injection at one end, and the filling resin uses Epoxy resin and add corresponding diluent and curing agent to adjust resin viscosity and curing time. The ratio of resin curing system is: epoxy resin, polyamide curing ...

Embodiment 3

[0014] see figure 1 , the kenaf woven fabric 1 is laid layer by layer in the prefabricated mold 2 in an orderly manner according to the designed laying angle and the number of layers, and each layer of kenaf woven fabric is cross-laminated, and the general hemp woven fabric laying layer Number is 4 layers~12 layers, and kenaf woven fabric lays 8 layers in the present embodiment, and the laying angle of each layer of kenaf woven fabric from beginning to end is successively 0 °, 90 °, +30 °,-30 °, +30°, -30°, 0°, 90°. The volume content of kenaf fiber is not less than 40%, then the mold is closed and sealed, and the mold is filled by the closed mold molding process--resin transfer molding process (RTM process). Use epoxy resin and add corresponding diluent and curing agent to adjust resin viscosity and curing time. The ratio of resin curing system is: epoxy resin, polyamide curing agent, and reactive diluent according to a certain ratio of 10: (1.2~2.4 ): (0.6~0.8), the curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com