Production method for moisture-absorbing sweat-releasing high-strength high-modulus polyethylene

A high-strength, high-modulus, moisture-absorbing and sweat-wicking technology, which is applied in the field of polyethylene fibers, can solve problems such as poor moisture absorption and sweat-wicking properties and affect comfort, and achieve enhanced moisture absorption, good moisture absorption and sweat-wicking properties, and large specific surface area. Effect

Inactive Publication Date: 2018-12-28

盐城优和博新材料有限公司

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention provides a production method of high-strength and high-modulus polyethylene for moisture absorption and perspiration, which aims to solve the problem that the moisture regain of the fiber is almost zero, resulting in very poor moisture absorption and perspiration, which affects the comfort

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

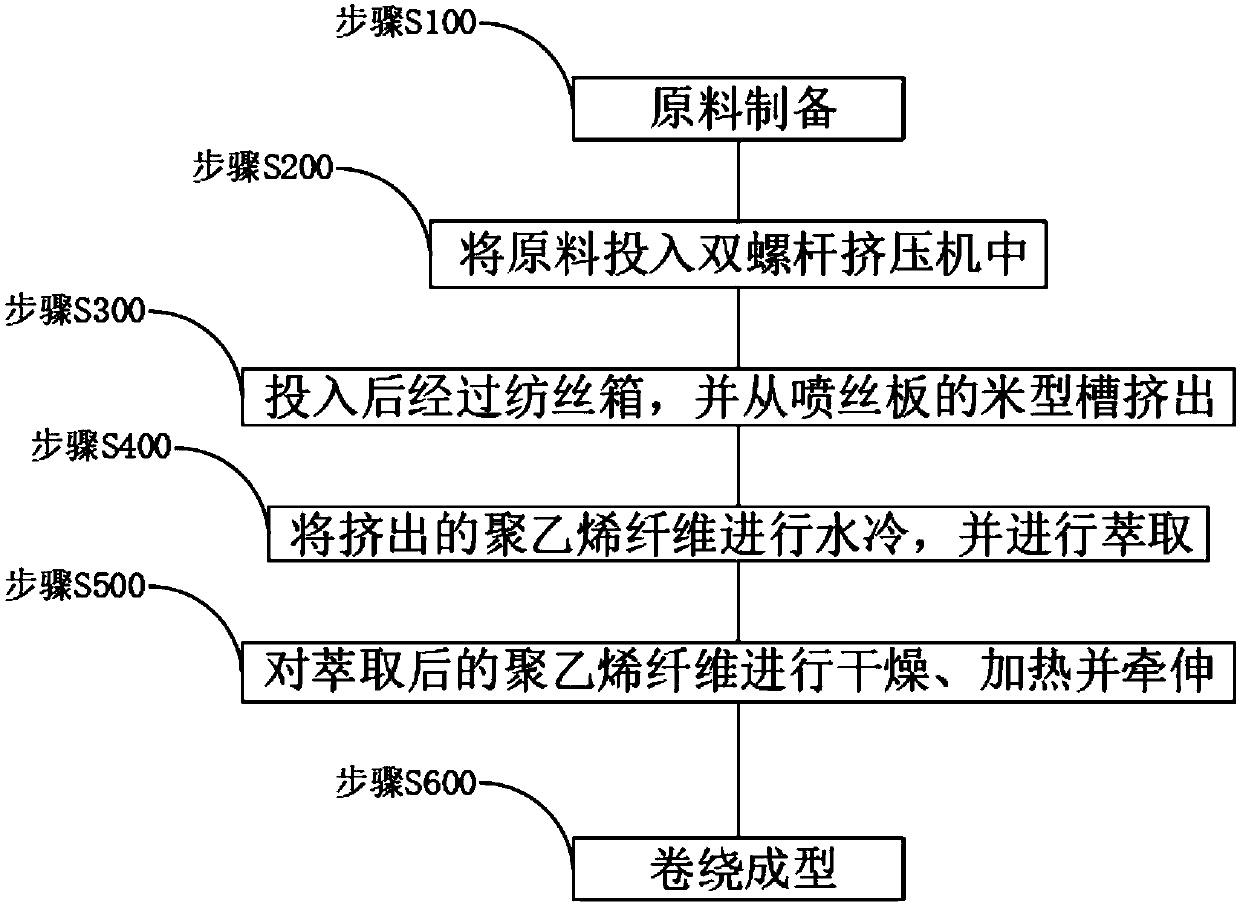

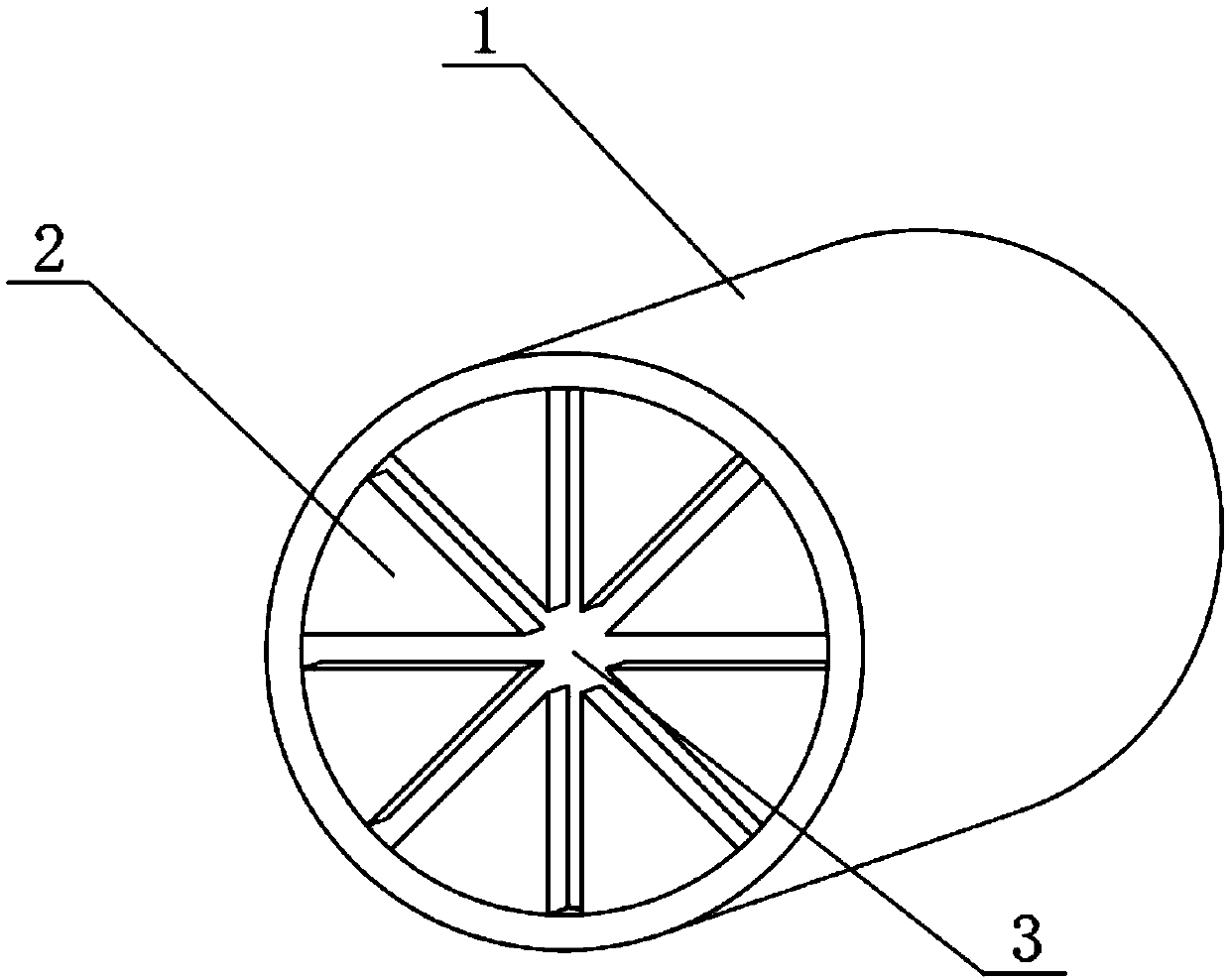

The invention discloses a production method for moisture-absorbing sweat-releasing high-strength high-modulus polyethylene. The production method for the moisture-absorbing sweat-releasing high-strength high-modulus polyethylene comprises the following steps: S100, preparing a raw material; S200, putting the raw material into a twin-screw extruder; S300, after the raw material is put into the twin-screw extruder, enabling the raw material to pass through a spinning box, and extruding the raw material from *-shaped slots of a spinning plate; S400, performing water cooling on the extruded polyethylene fibres, and extracting; and S500, drying, heating and drawing the extracted polyethylene fibres; and after the raw material is extruded from the spinning plate, extruding the polyethylene fibreraw material into * shapes, wherein the ultrafine high-strength polyethylene fibres with the *-shaped cross sections are provided with eight grooves, are large in specific surface area, can guide moisture and are breathable; the specific surface area of a single fibre of 0.4 to 0.5 dpfp is 2 to 3 times that of the single fibre of 2 dfp; and a good capillary effect can be achieved by the spaces among the fibres, so that the moisture absorbing property of the fibres is enhanced. Therefore, the ultrafine high-strength polyethylene fibres with the *-shaped cross sections has good moisture absorbing property and sweat releasing property when the ultrafine high-strength polyethylene fibres with the *-shaped cross sections are applied in the fields of home textile and underwear.

Description

technical field The invention belongs to the technical field of polyethylene fibers, and in particular relates to a production method of moisture-absorbing and sweat-wicking high-strength and high-modulus polyethylene. Background technique Polyethylene fiber is a fiber material obtained by spinning polyethylene by melt spinning, including short fibers and filaments. The mechanical strength of this fiber can be adjusted through the spinning process parameters, and the wet strength and elongation The same state, polyethylene fiber has the advantages of high strength, low density, good insulation, etc., but the low heat carrying capacity and cold creep limit its application, mainly used in the production of various industrial textiles, especially filter materials, tents Cloth and mesh belt and other products. High-strength polyethylene fiber is currently widely used in the fields of labor protection, home textiles, ropes, civil construction, home textiles, and clothing. It is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01D5/253

CPCD01D5/253

Inventor 陈林金效东张亮王亚军

Owner 盐城优和博新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com