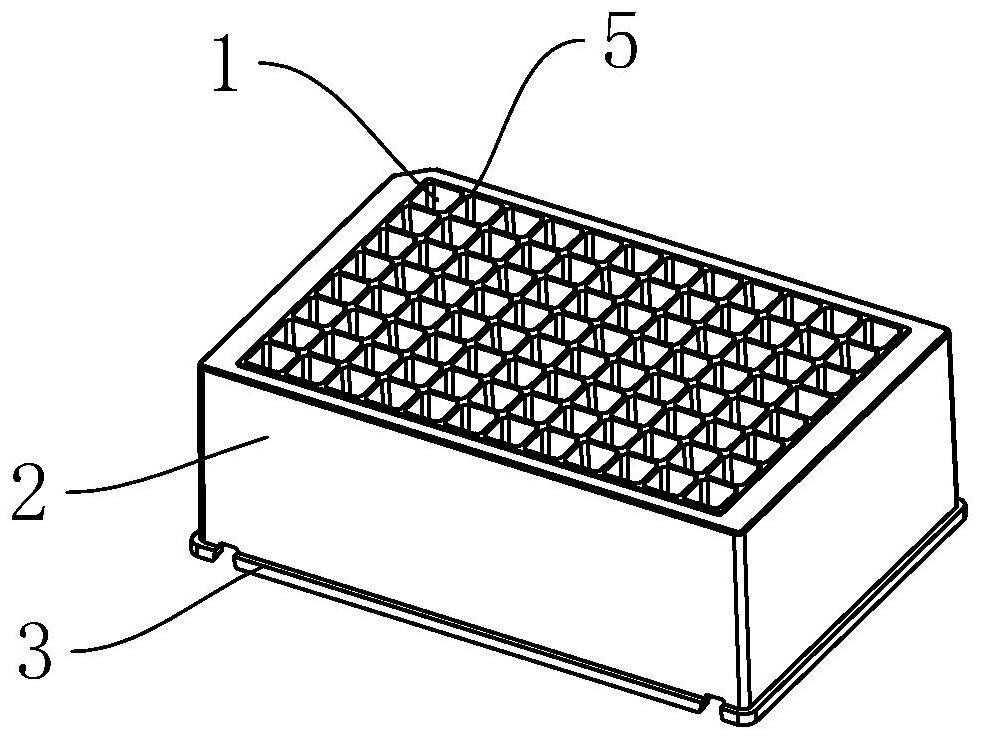

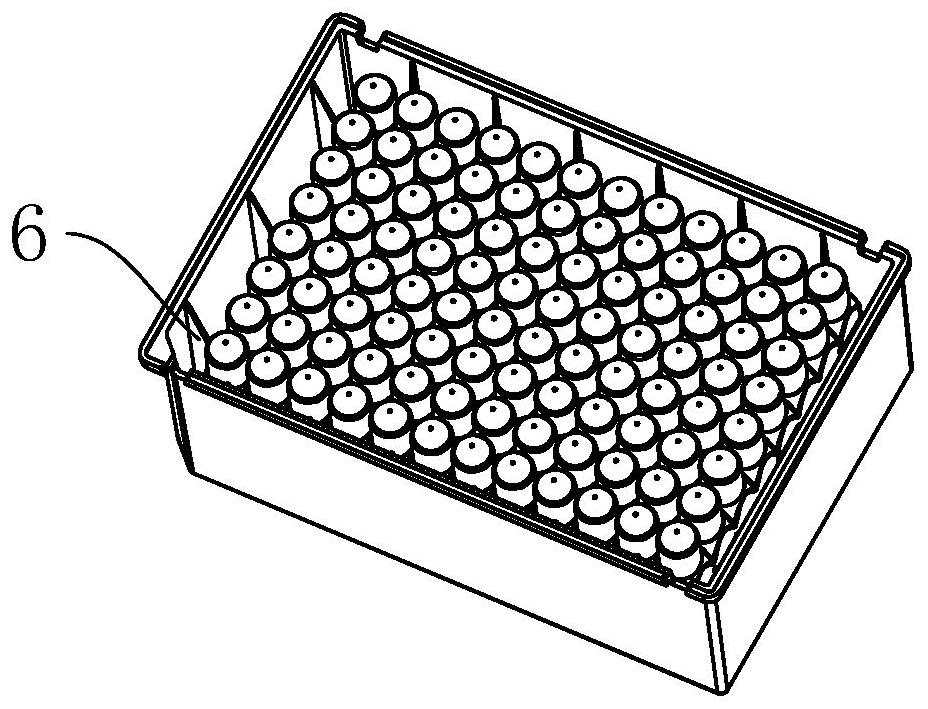

Deep-well plate with high nucleic acid extraction rate and preparation method of deep-well plate

A deep-well plate, extraction rate technology, applied in biochemical equipment and methods, DNA preparation, biomass post-processing, etc., can solve the problems of slow sedimentation of magnetic beads and easy resuspension, loss of magnetic beads, and reduction of nucleic acid extraction volume. Achieve consistent product characteristics, reasonable structure design, and reduce the loss of magnetic beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

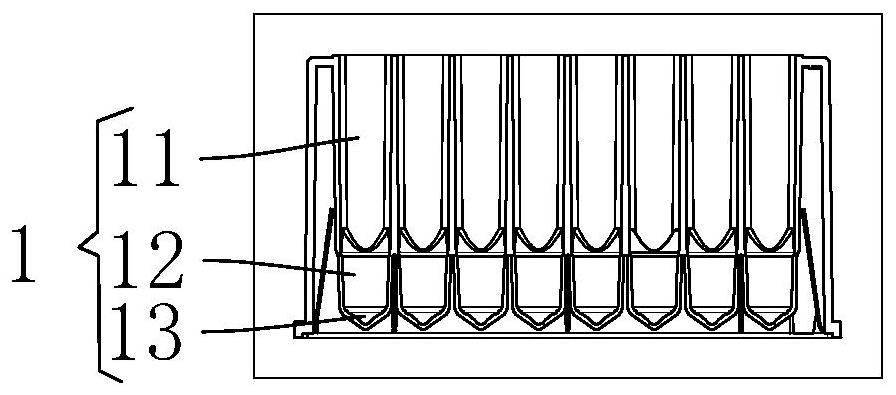

Embodiment 1

[0062] Put ordinary medical-grade polypropylene granule raw materials into the drum cavity of low-pressure plasma equipment, vacuumize the cavity to a pressure of 0.15mbar, start the plasma generator, and inject inert gas nitrogen. The process conditions are power 80 watts, pressure 0.3mbar , the processing time is 120 seconds, then the inert gas valve is closed, and N-vinylpyrrolidone is introduced into the volatile gas under low pressure. The process conditions are 40 watts of power, 0.4 mbar of pressure, and the processing time of 300 seconds. Measure the contact angle of pure water in the hole, the average value is 86.9°, the product is soaked in ethanol or wipe the surface with ethanol and then dry, then measure the contact angle at the same position, the average value is 87.3° (such as figure 1 ).

[0063] The contact angle changes very little, indicating that there is no precipitate on the surface of the product, and the hydrophilic property comes from the material itse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com