Capillary structure of heat dissipation element, heat dissipation element and preparation method of capillary structure

A capillary structure and heat dissipation element technology, which is applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of high production cost, complicated production process and high market price of capillary structure, and achieve a porous structure and Controllable size, simple material and equipment conditions, good surface quality and color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

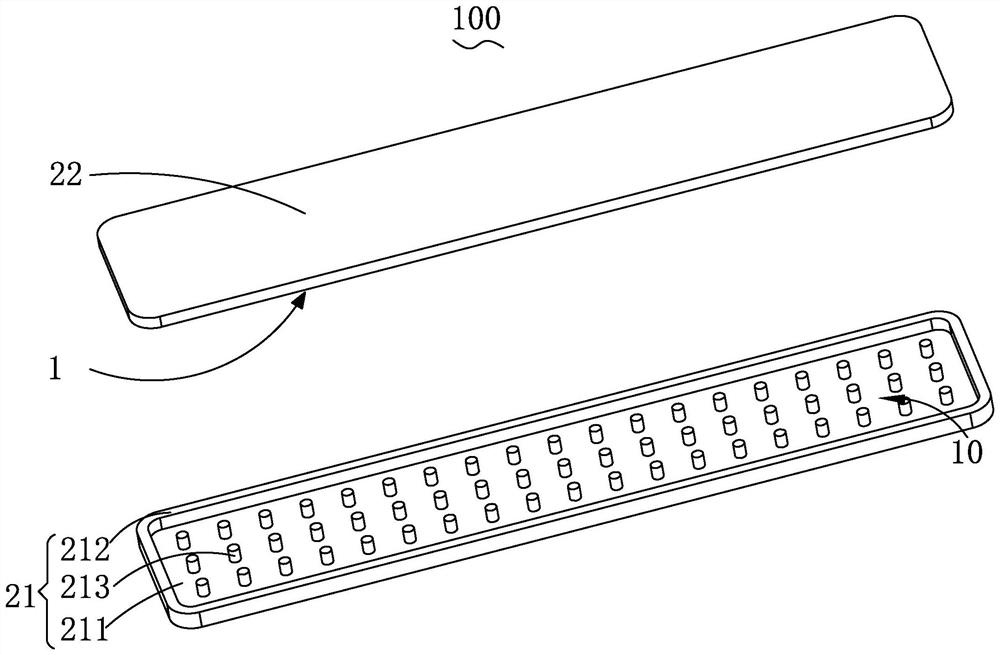

[0041] like Figure 4 As shown, it is a schematic flow sheet of the preparation method of the heat dissipation element provided by the invention, which comprises: S1: mixing the copper powder and the pore-forming agent to obtain a mixed powder;

[0042] S2: the binder is dispersed in the solvent to obtain a mixed solvent;

[0043] S3: adding the mixed powder to the mixed solvent, fully stirring in the mixer;

[0044] S4: add stabilizer, dispersant, surfactant, antioxidant and continue to stir to obtain copper metal slurry;

[0045] S5: the copper metal paste is coated on the upper cover plate by a blade coating method or a screen printing method;

[0046] S6: drying the upper cover plate coated with copper metal slurry;

[0047] S7: Passing nitrogen and hydrogen into the sintering process at high temperature.

Embodiment 1

[0049] Example 1: Take the electrolytic copper powder with an average particle size of 10 μm and the ammonium chloride particles with a particle size of 70-100 μm obtained by ball milling or crushing and sieving, and mix them together in a mass ratio of 3:1 to obtain a mixed powder. The mixed powder accounts for 70% of the mass of the copper metal slurry, and acrylic resin (PMMA) is dispersed in the solvent xylene as a binder to obtain a PMMA-xylene solution with a mass fraction of 25%, and the mixed powder is added to 25 % PMMA-xylene solution, after the mixer is fully stirred, add phosphite with a mass fraction of 0.5% of the copper metal slurry as a stabilizer, and methyl pentane with a mass fraction of 0.5% of the copper metal slurry. Alcohol is used as a dispersant, sodium dodecyl sulfate with a mass fraction of 0.5% of the copper metal slurry is used as a surfactant, and citric acid with a mass fraction of 1% of the copper metal slurry is used as an antioxidant, and the s...

Embodiment 2

[0053] Example 2: Take the electrolytic copper powder with an average particle size of 1 μm and the ammonium chloride particles with a particle size of 70-100 μm obtained by ball milling or crushing and sieving, and mix them together in a mass ratio of 3:1 to obtain a mixed powder. The mixed powder accounts for 70% of the mass of the copper metal slurry. The mixed powder is added to 25% of PMMA-xylene solution. After the mixer is fully stirred, 0.5% of stabilizer and 0.5% of dispersant are added in turn. , 0.5% surfactant, 1% antioxidant, and continue to stir for 0.5 to 6h. Scratch the mixed copper metal paste onto the upper cover of a specific heat dissipation element, then put it in an oven at 90 to 110 ° C for 20 to 120 minutes, dry the solvent, and put it into the sintering furnace. Pour N2 / H2 into it, and sinter at 700-850° C. for 20-120 minutes to finally obtain an upper cover plate with capillary structural elements. The upper cover plate and the lower cover plate are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com