A rubber foaming oil-adsorbing material and a preparing method thereof

A technology of rubber foaming and oil-absorbing materials, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of small oil absorption, poor overall performance of rubber foaming oil-absorbing materials, and low raw rubber strength, and achieve industrialization Production, easy industrial production, high oil absorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

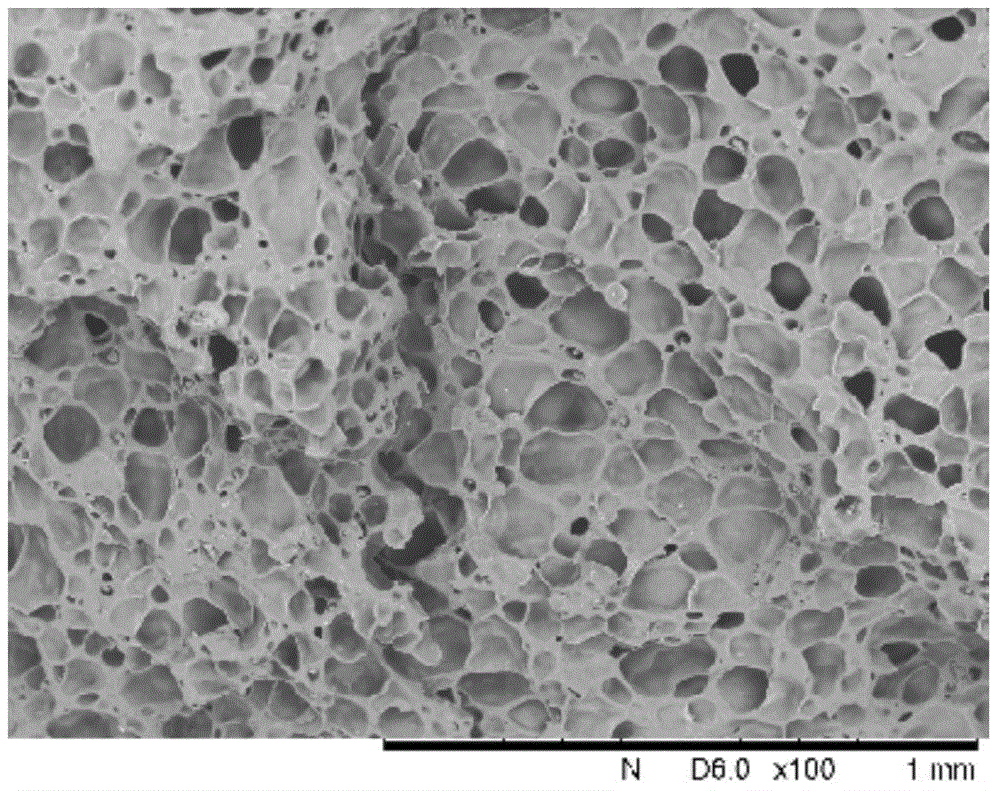

Image

Examples

Embodiment 1

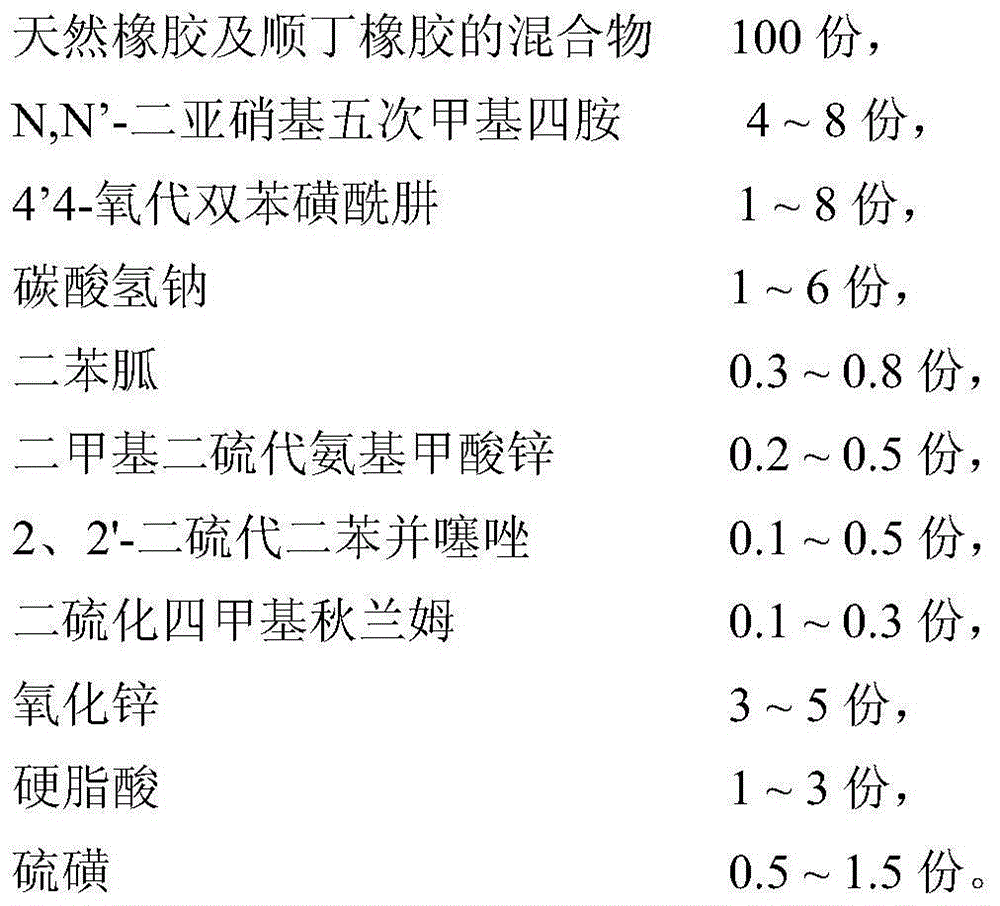

[0026] The rubber foam oil-absorbing material of the present embodiment comprises the following components by weight:

[0027]

[0028] The preparation method of the rubber foam oil-absorbing material of the present embodiment comprises the following steps:

[0029] (1) Mix 90 parts of natural rubber and 10 parts of butadiene rubber on an open mill, control the temperature of the roll at 50°C, and add N,N'-dinitrosopentamethylene in turn after 10 minutes of rolling 4 parts of tetramine, 4 parts of 4'4-oxobisbenzenesulfonyl hydrazide, 1 part of sodium bicarbonate, 0.3 parts of diphenylguanidine, 0.5 parts of zinc dimethyl dithiocarbamate, 2,2'-disulfide 0.4 parts of substituted dibenzothiazole and 0.3 parts of tetramethylthiuram disulfide, and continued refining for 3 minutes;

[0030] (2) Add 5 parts of zinc oxide and 2 parts of stearic acid to the material obtained in step (1), and continue refining for 5 minutes;

[0031] (3) Add 1 part of sulfur to the material obtaine...

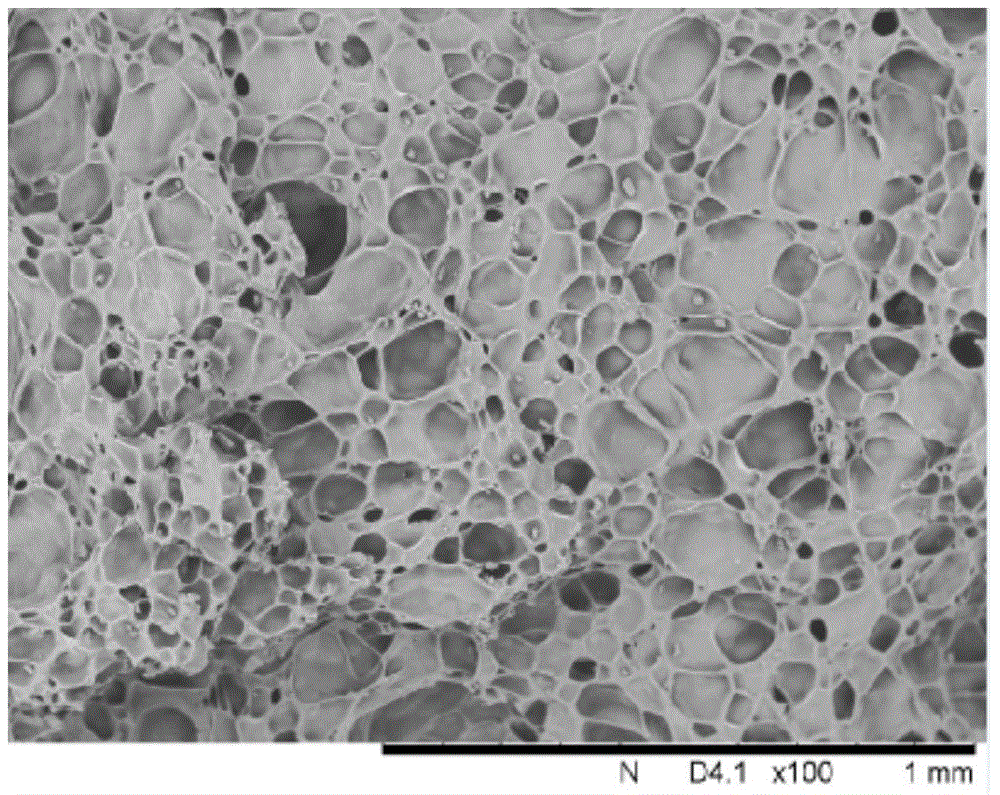

Embodiment 2

[0038] The rubber foam oil-absorbing material of the present embodiment comprises the following components by weight:

[0039]

[0040] The preparation method of the rubber foam oil-absorbing material of the present embodiment comprises the following steps:

[0041] (1) Knead a mixture of 70 parts of natural rubber and 30 parts of butadiene rubber on an open mill, control the roll temperature at 52°C, and add N,N'-dinitrosopentamethylene in turn after 11 minutes of kneading 8 parts of tetramine, 1 part of 4'4-oxobisbenzenesulfonyl hydrazide, 1 part of sodium bicarbonate, 0.8 parts of diphenylguanidine, 0.2 parts of zinc dimethyl dithiocarbamate, 2,2'-disulfide 0.5 part of substituted dibenzothiazole and 0.1 part of tetramethylthiuram disulfide, continue refining for 3 minutes;

[0042] (2) Add 3 parts of zinc oxide and 3 parts of stearic acid to the material obtained in step (1), and start refining for 3 minutes;

[0043] (3) Add 1 part of sulfur to the material obtained ...

Embodiment 3

[0050] The rubber foam oil-absorbing material of the present embodiment comprises the following components by weight:

[0051]

[0052] The preparation method of the rubber foam oil-absorbing material of the present embodiment comprises the following steps:

[0053] (1) Knead a mixture of 50 parts of natural rubber and 50 parts of butadiene rubber on an open mill, control the roll temperature at 54°C, and add N,N'-dinitrosopentamethylene in turn after 13 minutes of kneading 5 parts of tetramine, 2 parts of 4'4-oxobisbenzenesulfonyl hydrazide, 1 part of sodium bicarbonate, 0.5 parts of diphenylguanidine, 0.5 parts of zinc dimethyl dithiocarbamate, 2,2'-disulfide 0.3 parts of substituted dibenzothiazole and 0.2 parts of tetramethylthiuram disulfide, and the refining time was continued for 5 minutes;

[0054] (2) Add 5 parts of zinc oxide and 1 part of stearic acid to the material obtained in step (1), and continue refining for 5 minutes;

[0055] (3) Add 1 part of sulfur to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com