Super-hydrophobic-oleophylic porous material, and preparation method and application thereof

A porous material and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of oil-water separation efficiency to be improved, poor stability and corrosion resistance, complex preparation process, etc., to achieve good industrial The effect of application prospect, high oil absorption ratio and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 A kind of preparation method of superhydrophobic-oleophilic porous material can be carried out in the following steps:

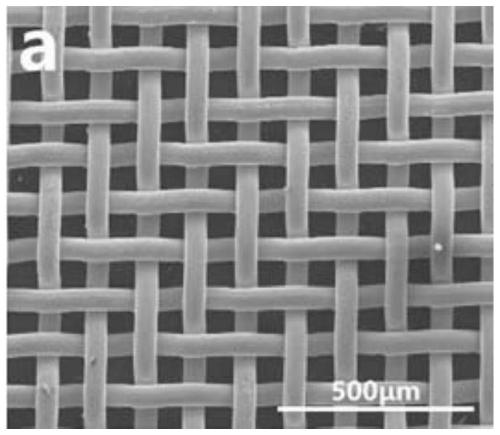

[0042] (1) Copper mesh with a pore size of 50 microns (refer to the morphology Figure 1A ) after being ultrasonically cleaned with acetone and water in sequence, and then dried at 80°C to remove surface organic substances;

[0043] (2) Dissolve 0.1 g of perfluorooctyltrimethoxysilane in 50 mL of ethanol, then add it into 50 mL of phytic acid aqueous solution (2 mg / mL), and mix to form an impregnation solution.

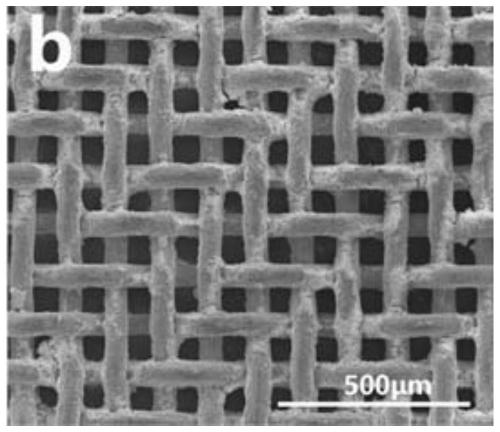

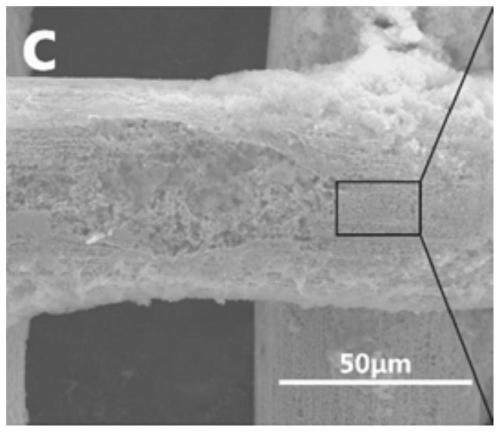

[0044] (3) Immerse the copper grid in the above impregnation solution, soak it at 30°C for 8 hours, then take it out, and dry it at 80°C to obtain a superhydrophobic-oleophilic porous material (see Figure 1B-Figure 1D ).

[0045] The water contact angle of the superhydrophobic-oleophilic porous material is 155°, the contact angle of toluene is 0°, and the rolling angle is 4°. The oil-water separation experiment was carried out...

Embodiment 2

[0048] Example 2 A kind of superhydrophobic-lipophilic porous material is basically the same as the preparation method of the superhydrophobic-lipophilic porous material in Example 1, the difference is: the metal mesh base has a different aperture, and the aperture is 80 microns; the copper mesh is used in the dipping solution Soak at 10°C for 10 hours; the mass ratio of phytic acid to fluorine-containing silane is 1:0.5, and the amount of phytic acid accounts for 0.5‰ of the mass of the soaking solution.

[0049] Tests show that the water contact angle of the superhydrophobic-oleophilic porous material is 156°, the contact angle of toluene is 0°, and the rolling angle is 4°; the oil-water separation experiment performed with reference to the method of Example 1 shows that the oil-water separation efficiency is 96% ; The oil absorption rate is 8mL / min.

Embodiment 3

[0050]Example 3 A kind of superhydrophobic-lipophilic porous material is basically the same as the preparation method of the superhydrophobic-lipophilic porous material in Example 1, the difference is: the aperture of the metal mesh base is different, and the aperture is 100 microns; the copper mesh is in the dipping solution Soak for 4 hours at 40°C; the mass ratio of phytic acid to fluorine-containing silane is 1:2, and the amount of phytic acid accounts for 2‰ of the mass of the soaking solution.

[0051] Tests show that the water contact angle of the superhydrophobic-oleophilic porous material is 158°, the contact angle of toluene is 0°, and the rolling angle is 4°; the oil-water separation experiment performed with reference to the method of Example 1 shows that the oil-water separation efficiency is 95% ; The oil absorption rate is 11mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com