Patents

Literature

39results about How to "Stable corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-hydrophobic-oleophylic porous material, and preparation method and application thereof

InactiveCN110280222ASimple processLow costFatty/oily/floating substances removal devicesOther chemical processesMicro nanoSilanes

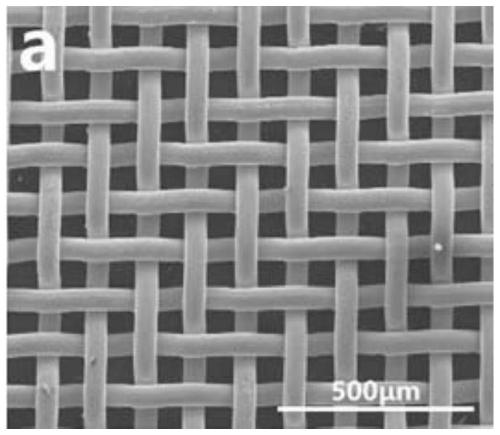

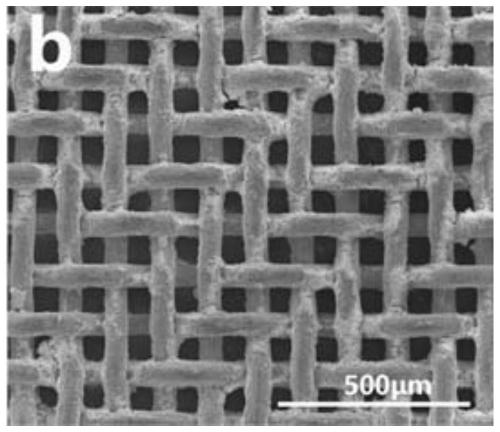

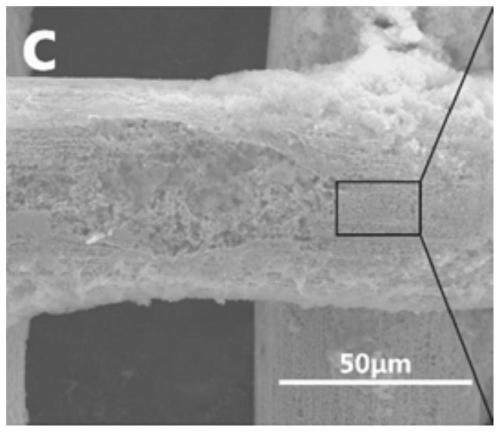

The invention provides a super-hydrophobic-oleophylic porous material, and a preparation method and application thereof. The super-hydrophobic-oleophilic porous material comprises a metal grid structure and an organic-inorganic hybrid coating covering the metal grid structure, wherein the organic-inorganic hybrid coating is mainly formed by the reaction of phytic acid and fluorine-containing silane. According to the super-hydrophobic-oleophylic porous material, and the preparation method and application thereof, through the cocondensation of the phytic acid and the fluorine-containing silane, and the chelation of the phytic acid and the metal grid structure, an organic-inorganic hybrid micro-nano structure is formed on the surface of the metal grid structure, and the super hydrophobic-oleophilic modification of the surface of the metal grid structure is realized. The super-hydrophobic-oleophilic porous material provided by the invention can float on a water surface, can recover different kinds of floating oil on water efficiently, and has stable super hydrophobicity and corrosion resistance in a high salt spray environment; the oil absorption rate and oil-water separation efficiency are high; meanwhile, the preparation method is simple, the cost is low, large-scale preparation can be realized, and a very good industrial application prospect is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Surface antiseptic treating agent for cable bridge frame

InactiveCN101085889ARaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsWear resistantRare earth

The invention relates to a kind of corrosion-resistant and erosion resistant coating material, which in detail is a corrosion-resistant material for cable bridge surface. The invention adds flaky zinc powder concentration for traditional dacromet coating formulation, adds penetrating agent, surface active agent, hardening agent and rare earth material. The coating layer on the surface is characterized by high adhesion power, good wearing resistant performance, good antiweatherability and stable chemically-resistant property, and suitability for wild environment utilization for a long time, which as long as 30 years.

Owner:孔繁明

Electrostatically conductive oil-tolerant paint containing rich zinc and silicic acid

InactiveCN1390895AReduce manufacturing costFast dryingElectrically-conductive paintsAlcoholSilicic acid

An antistatic paint is prepared through mixing ethyl n-silicate with absolute alcohol, stirring, alcoholysis reaction, dropping hydrochloric acid diluted by purified water to make pH=2-3, laying aside, adding organic silanamine, stirring, adding zinc powder and stirring. Its advantages are high electrostatic conductivity and corrosion resistance, low cost, fast dry, and high firmness of film.

Owner:黄观明 +1

Silver-free and brittle fracture-resistant 18K rose gold and processing technology thereof

The invention discloses silver-free and brittle fracture-resistant 18K rose gold and a processing technology thereof. The silver-free and brittle fracture-resistant 18K rose gold comprises the following components in percent by weight: 0.2-0.4wt.% of Ba, 0.6-0.8wt.% of V, 1.2-1.6wt.% of Ni, 1.0-1.2wt.% of Sb, 8.0-12.0wt.% of In, 74.0-76.0wt.% of Au and the balance of copper. The invention providesnovel silver-free 18K rose gold and the processing technology thereof, and the characteristic of low-temperature brittle fracture of the conventional rose gold is avoided. Through the innovation andoptimization of the alloy components, the development bottleneck of a 18K red gold material for jewelries is broken through; implementation and industrialization of the material achieve plenteous economic results and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

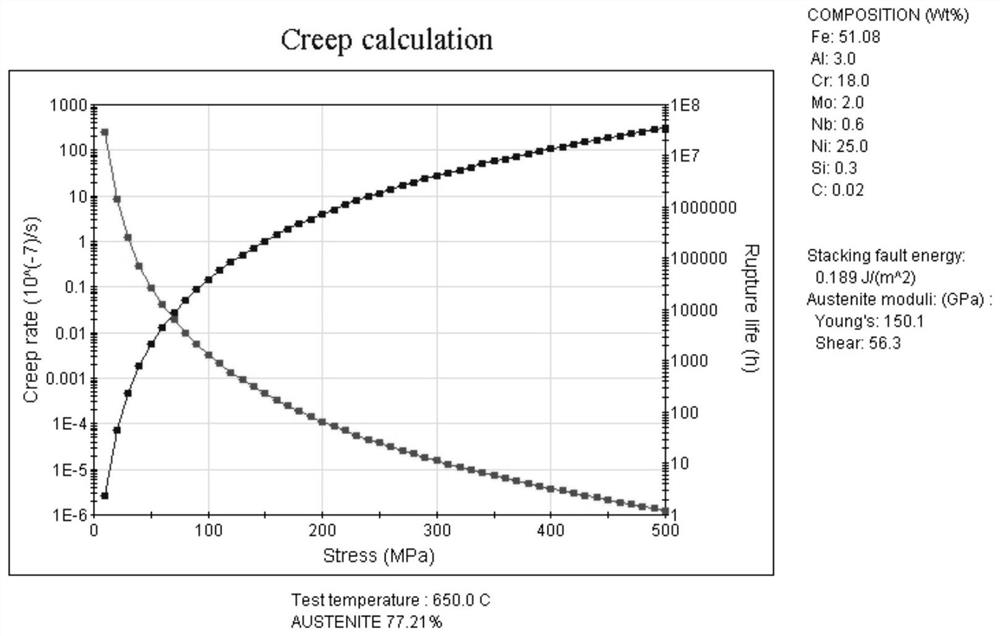

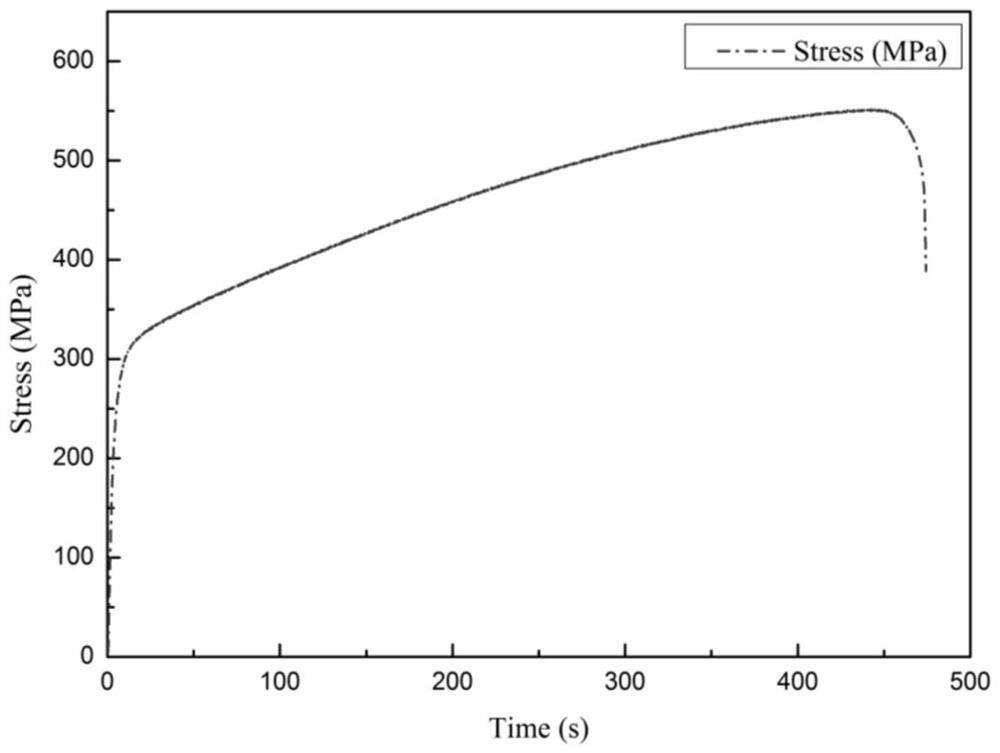

High-temperature and corrosion resistant aluminum-containing austenitic stainless steel and preparation method

InactiveCN113151747AImprove corrosion resistanceGood high temperature mechanical propertiesNuclear energy generationCooling arrangementSS - Stainless steelOxidation resistant

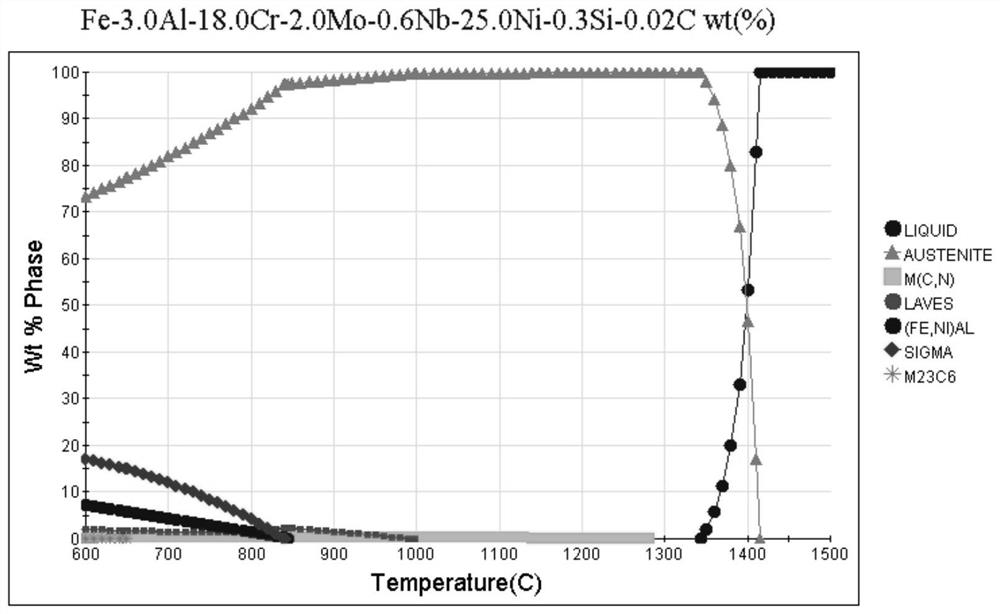

The invention discloses high-temperature and corrosion resistant aluminum-containing austenitic stainless steel and a preparation method. The high-temperature and corrosion resistant aluminum-containing austenitic stainless steel comprises, by weight, 15%-30% of Ni, 15%-25% of Cr, 2.5%-8% of Al, 1%-3% of Mo, 0.1%-1% of Si, 0.1%-2% of Nb, 0.02%-0.2% of C, 0.02%-0.2% of Y / Hf and the balance Fe. According to the aluminum-containing austenitic stainless steel, the content of Cr is increased to 15-25 wt.%, the content of Al is increased to 2.5-8 wt.%, the aluminum-containing austenitic stainless steel contains Cr and Al elements with the enough high content, both Cr and Al are key elements for improving the oxidation resistance, and the high content of Cr and Al contributes to formation of an Al-Cr oxidation film. A stable and compact Cr2O3 oxidation film can be formed on the surface of the alloy, and the oxidation resistance of the material is improved; and meanwhile, the Al2O3 oxidation film can be formed on the surface of the alloy in an oxidizing atmosphere, the Al2O3 layer is good in thermodynamic stability, low in growth rate and more protective in an extreme environment, and the Al can further form a large number of B2-NiAl phases in a matrix. The using temperature of the material in a high-temperature oxidizing atmosphere is increased, the corrosion resistance of the material is improved, and the material can be used in a high-temperature extreme environment.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Aluminum and aluminum alloy passivation solution, preparation method and using method thereof

ActiveCN104451634AAvoid the problem of poor corrosion resistanceQuality improvementMetallic material coating processesChromate saltSodium fluoride

The invention provides an aluminum and aluminum alloy passivation solution, preparation method and using method thereof; the raw material ratios of the passivation solution are as follows: 3-5g / L of zinc chromate, 0.5-1g / L of cobaltous sulfate, 2-3g / L of zirconium sulfate, 0.5-1.5g / L of sodium fluoride, 2-4g / L of nitric acid, 1-2g / L of citric acid, and the rest amount is water. A passivation working solution (bath solution) which is prepared by diluting the passivation solution is stable, low concentration, fast in passivation speed, low void ratio of the obtained passivation film, is able to form a yellow chromate film layer on surface of the aluminum product, has an excellent anti-corrosion property, and is able to greatly increase the paint or coating layer adhesive force on the work piece. The property of the formed passivation film for resisting neutral salt mist is more than 120 hours.

Owner:HUNAN JINYU CHEM

Electrostatically conductive anticorrosion epoxyxylene phenolic paint

InactiveCN1390904AReduce manufacturing costFast dryingEpoxy resin coatingsElectrically-conductive paintsEpoxySilicate

An antistatic anticorrosion paint is prepared through mixing epoxy resin E42, meta-xylene phenolic resin, organosilicon resin, dibutyl o-benzoate and ethyl n-silicate, adding Ti powder, stirring, adding absolute alcohol or ethanediamine, and stirring. Its advantages are high electrostatic conductivity and corrosion resistance, low cost, fast dry and firm film.

Owner:黄观明 +1

Stable manufacturing method of high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for pressure vessel

PendingCN112775204AHigh strengthHigh strength and high toughnessFurnace typesHeat treatment furnacesThick plateHeat treated

The invention relates to a stable manufacturing method of an aluminum alloy thick plate, in particular to a stable manufacturing method of a high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for a pressure vessel. The invention aims to solve the problem that the aluminum alloy plate with high strength, high toughness, high allowable stress and high corrosion resistance at the same time is difficult to prepare in the prior art. The manufacturing method comprises the following steps of 1, weighing and smelting; 2, casting; 3, homogenizing annealing treatment; 4, heating; 5, primary hot rolling; 6, secondary hot rolling; 7, solid solution; 8, high-temperature annealing; 9, primary aging; 10, secondary aging; 11, stabilizing heat treatment; 12, stretching; and 13, tertiary aging. The stable manufacturing method is mainly used for stably manufacturing the high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for the pressure vessel.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Aluminum passivation solution and preparation method thereof

InactiveCN106756939AAvoid the problem of poor corrosion resistanceQuality improvementMetallic material coating processesPorositySodium fluoride

The invention provides an aluminum passivation solution, a preparation method and an application method thereof. The raw material ratio of the passivation solution is as follows: 2-5 g / L of zinc chromate, 0.5-1 g / L of cobalt sulfate, 2-3 g / L of zirconium silicate, 0.5-1.5 g / L of sodium fluoride, 2-4 g / L of sulfuric acid, 1-2 g / L of citric acid, and the balance of water. A passivation working solution (a bath solution) prepared from the passivation solution by diluting is stable, relatively low in concentration, and high in passivation speed; an obtained passivation film is low in porosity, and high in adhesive force, can form a yellow chromate film layer on the surface of an aluminum material, has great corrosion resistance and can greatly improve the adhesive force of workpieces with paint or plastic-sprayed coating; and the formed passivation film can resist neutral salt mist for 120 hours above.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Environmentally-friendly waterborne rust-based anticorrosion coating

InactiveCN108299981AImprove adhesionStable corrosion resistanceAnti-corrosive paintsMolecular sieveEmulsion

The invention belongs to the technical field of rust-based anticorrosion coatings, and particularly relates to an environment-friendly waterborne rust-based anticorrosion coating. The coating comprises water, a styrene-acrylic emulsion, a carbon nanotube composite material, a modified aluminum phosphate molecular sieve, a substrate adhesion promoter, a humectant, a flash rust inhibitor aid, a thickener and a surface tension regulator. Compared with coatings in the prior art, the coating in the invention has the following advantages: the modified aluminum phosphate molecular sieve in the coating can react with iron rust after being hydrolyzed in order to form an insoluble complex, the carbon nanotube composite material in the coating is matched with other raw materials to fully infiltrate the surface of steel, and fully reacts with acidic iron rust to form a stable structure in order to enhance the adhesion of the coating to a substrate, the coating forms a continuous sealing coating layer on the surface of the rust layer to achieve stable corrosion resistance, and the coating also has the characteristics of zero organic solvent components, friendliness and no pollution to the environment, short film formation time, simple construction process and good antirust performance.

Owner:安徽喜宝高分子材料有限公司

Li and Sn containing gold alloy for 14K red gold with low-temperature brittle fracture inhibition

The invention discloses Li and Sn gold alloy for 14K red gold with low-temperature brittle fracture inhibition. The alloy comprises, by weight, 0.2-0.4wt.% of Li, 0.4-0.6wt.% of V, 1.5-1.8wt.% of Sn,2.0-2.4wt.% of Al, 12.0-20.0wt.% of Ag, 57.0-59.0wt.% of Au and the balance of copper. The problem about lag in technology that existing 14K red gold materials are low-temperature brittle is solved; through innovation and optimization of alloy composition, the bottleneck of the 14K red gold material for jewelry is broken through; the implementation of the material and the industrialization can predictably achieve substantial economical results and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

Li-containing and Re-containing gold alloy capable of inhibiting low-temperature brittleness and used for 10K red gold

The invention discloses Li-containing and Re-containing gold alloy capable of inhibiting low-temperature brittleness and used for 10K red gold. The alloy comprises the following components in percentage by weight: 0.2 to 0.4 percent of Li, 0.3 to 0.5 percent of Re, 0.2 to 0.3 percent of Ti, 3.0 to 4.5 percent of Sn, 25.0 to 32.0 percent of Ag, 41.0 to 43.0 percent of Au and the balance of copper.The patent solves the existing conditions that the current 10K red gold material has low-temperature brittleness and the technology falls behind. The development bottleneck of the 10K red gold material for jewelry is broken through by innovating and optimizing the alloy components. Through prediction, implementation and industrialization of the material can achieve plenteous economic gain and social benefit.

Owner:GUANGZHOU YUZHI TECH CO LTD

Yellow Miao silver alloy with features of low density, light weight and corrosion resistance, and technology thereof

The invention discloses a yellow Miao silver alloy with the features of low density, light weight and corrosion resistance, and a technology thereof. The yellow Miao silver alloy comprises, by weight,0.8%-1.2% of Li, 3.0%-4.0% of Al, 4.0%-6.0% of Mg, 0.4%-0.6% of B, 0.5%-0.8% of Sc, 10.0%-15.0% of Zn, 30.0%-50.0% of Ag and the balance copper. According to the yellow Miao silver alloy, a light-weight selection scheme is provided for Miao silver alloy in China, and the obtained product not only has excellent yellow appearance, but also is extremely resistant to hydrogen sulfide corrosion. The requirements of product update of the jewelry industry and the industry upgrade in China can be promoted through the implementation and industrialization of the yellow Miao silver alloy effectively.

Owner:GUANGZHOU YUZHI TECH CO LTD

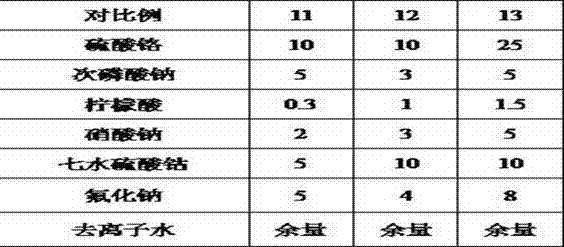

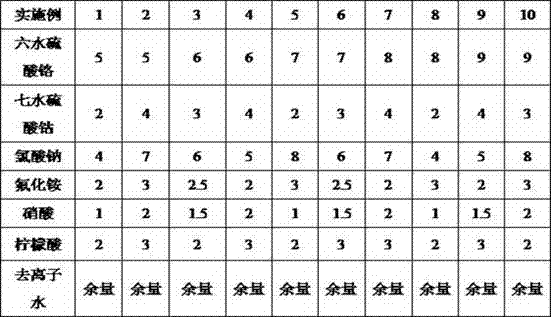

Passivation solution and preparation method thereof

InactiveCN106756929AQuality improvementStable passivation working fluidMetallic material coating processesPorositySalt spray test

The invention provides a passivation solution which is prepared by dissolving various raw materials in deionized water. The materials comprise 6-9 g / L of chromium sulfate hexahydrate, 2-4 g / L of cobalt sulfate heptahydrate, 4-8 g / L of sodium chlorate, 2-3 g / L of ammonium fluoride, 1-2 g / L of sulfuric acid, 2-3 g / L of citric acid and the balance water. According to an obtained passivation film, the corrosion resisting property is good, a salt spray test can be kept for 120 h or longer, the workpiece surface has no white rust or white spot, the porosity is low, and no sealing agent is needed for treatment.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Wear-resistant nickel-allergy-free 18K platinum material for jewelry and processing technology thereof

The invention discloses a wear-resistant nickel-allergy-free 18K platinum material for jewelry and a processing technology thereof. The alloy comprises following components in percentage by weight: 0.8 to 1.0 wt.% of Ca, 0.2 to 0.4 wt.% of Re, 0.6 to 1.4 wt.% of Fe, 2.0 to 3.0 wt.% of Ge, 8.0 to 10.0 wt.% of In, 10.0 to 12.0 wt.% of Ag, and the balance being gold. The provided K14 platinum does not contain nickel, which is allergic to human body and is usually contained by platinum alloy in the prior art. The provided K14 platinum does not contain any nickel, is friendly to human body, and isdeveloped by optimizing the components. The bottleneck of the jewelry field is broken through effectively. The application and industrialization of the K14 platinum may generate great economic and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

Non-nickel jewelry 18K platinum capable of avoiding low-temperature brittleness

The invention discloses non-nickel jewelry 18K platinum capable of avoiding low-temperature brittleness. The alloy comprises components including, by weight percent, 0.5 wt.%-0.8 wt.% of Li, 0.4 wt.%-0.6 wt.% of Re, 1.2 wt.%-1.5 wt.% of Ca, 4.0 wt.%-6.0 wt.% of Al, 10.0 wt.%-12.0 wt.% of In, 5.0 wt.%-6.0 wt.% of Ag, and the balance gold. The non-nickel jewelry 18K platinum solves the problem thatthe nickel element to which people are allergic is commonly contained in current K platinum. Through alloy component optimization and innovation, the non-nickel K platinum material friendly to the human body is developed, and the development bottleneck in the jewelry field is effectively broken through. It can be predicted that rich economic gains and social benefits can be obtained due to material implementation and industrialization.

Owner:GUANGZHOU YUZHI TECH CO LTD

Lightweight yellow low-silver alloy with excellent die casting performance and process thereof

The invention discloses a lightweight yellow low-silver alloy with excellent die casting performance and a process thereof. The alloy comprises, by weight, 0.5-0.8% of Sr, 15.0-18.0% of Al, 10.0-12.0% of Mg, 0.5-0.8% of Be, 4.0-5.0% of Mo, 20.0-24.0% of Zn, 29.0-31.0% of Ag and the balance copper. A lightweight selection scheme is provided for our Tibetan silver alloy through the alloy, and the obtained product has excellent yellow look and is extremely resistant to hydrogen sulfide corrosion. Through implementation and industrialization of the alloy, the demands for product upgrading and industrial upgrading in China's jewelry industry can be effectively promoted.

Owner:GUANGZHOU YUZHI TECH CO LTD

High-hardness and anti-corrosion yellow low silver content alloy for Miao silver jewellery and technology thereof

InactiveCN108842088AUnchanged for a long timeWith self-healing functionJewellerySocial benefitsHardness

The invention discloses a high-hardness and anti-corrosion yellow low silver content alloy for Miao silver jewellery and technology thereof. The high hardness and anti-corrosion yellow low silver content alloy comprises, by weight, 0.3-0.5wt.% of P, 0.2-0.4wt.% of C, 0.5-0.8wt.% of Li, 0.3-0.5wt.% of W, 1.0-1.5wt.% of Y, 8.0-1.0wt.% of Zn, 5.0-8.0wt.% of Ni, 40.0-50.0wt.% of Ag, and the balance copper. The material provides a solution for Chinese Miao silver alloy in materials science. Miao silver products have yellow color after processing, and the alloy has excellent high-hardness performance. Implement and industrialization of the material is capable of effectively promoting jewelry industry product renewal and industry upgrading in China. Difficulty in the industry can be overcome, andmeanwhile, abundant economic and social benefits can be obtained.

Owner:GUANGZHOU YUZHI TECH CO LTD

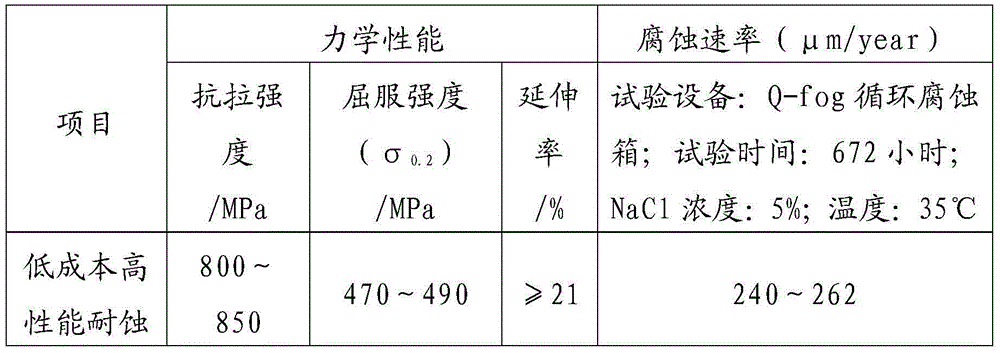

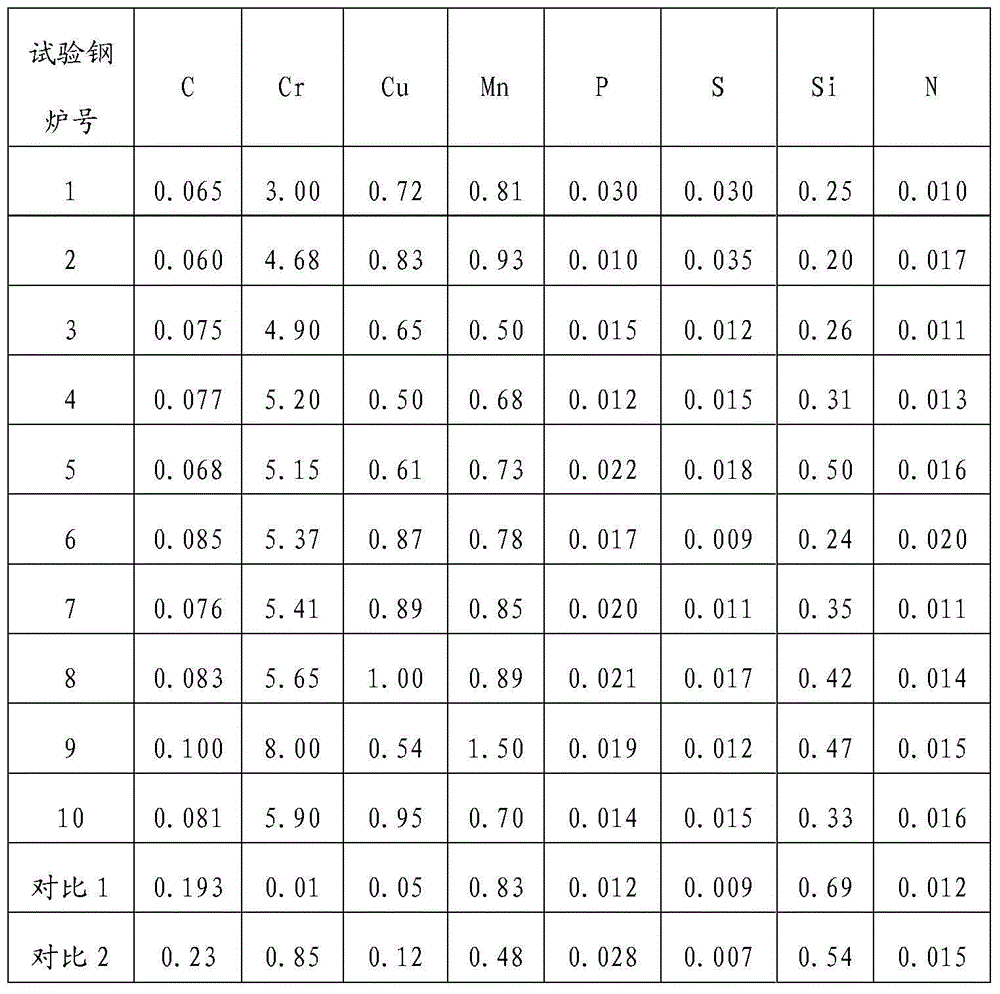

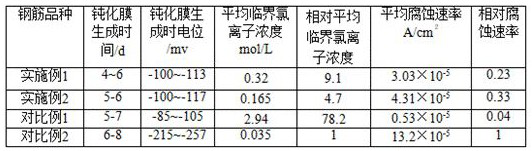

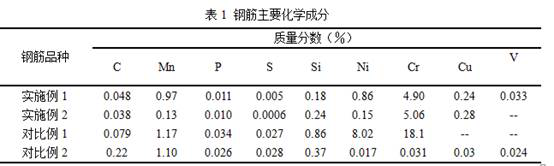

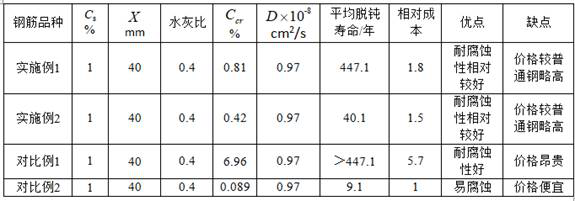

Low-cost high-performance corrosion-resistant steel bar and its manufacturing method

The invention relates to a low-cost, high-performance corrosion-resistant steel bar and a preparation method thereof. The low-cost, high-performance corrosion-resistant steel bar comprises the following chemical components by weight percent: 0.06-0.10wt% of C, 3-8wt% of Cr, 0.5-1wt% of Cu, 0.5-1.5wt% of Mn, 0.01-0.02wt% of N, not more than 0.03wt% of P, not more than 0.035wt% of S, 0.2-0.5wt% of Si and the balance of Fe and inevitable impurities. The preparation method comprises the steps of desulphurization pretreatment of molten iron, smelting by an electric furnace or a top and bottom combined blown converter, refining out of the furnace, continuous casting, heating of a casting blank, rolling and air-cooling by a cold bed. The low-cost, high-performance corrosion-resistant steel bar provided by the invention has the advantages of excellent corrosion resistance, relatively low cost and good mechanical properties, fatigue performance and welding performance.

Owner:武汉钢铁有限公司

Alloyed gray cast iron resistant to high-temperature aluminum and zinc liquid corrosion and its smelting process

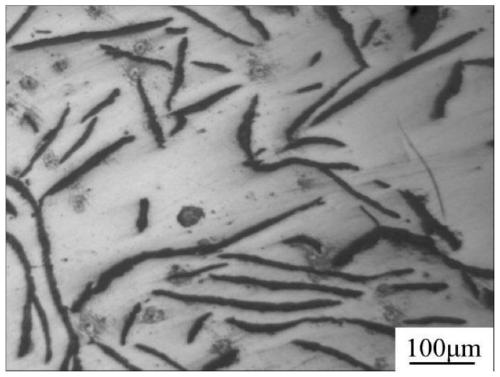

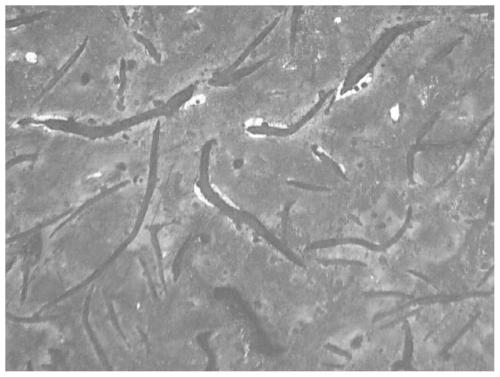

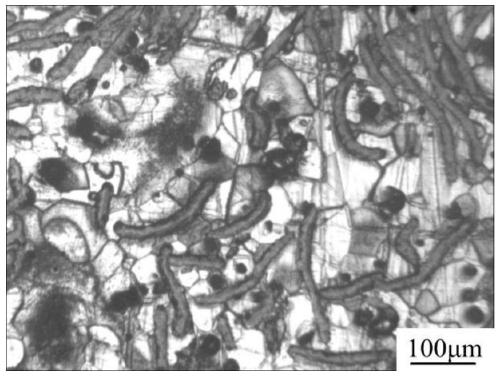

The invention belongs to the technical field of metallurgy, and particularly relates to high-temperature aluminum and zinc liquid corrosion resisting alloyed gray pig iron and a smelting technology thereof. The high-temperature aluminum and zinc liquid corrosion resisting alloyed gray pig iron specifically comprises following elements including, by weight percent, 3.1%-3.3% of C, 1.9%-2.2% of Si,0.8%-1.0% of Mn, smaller than or equal to 0.06% of P, smaller than or equal to 0.03% of S, 0.15%-0.3% of Cr, 0.05%-0.15% of Ni, 0.05%-0.2% of Cu, 0.15%-0.25% of Mo, 0.02%-0.04% of light rare earth andthe balance Fe. Through the synergistic effect of electrolytic copper, chromium, nickel, ferromolybdenum, the light rare earth and other alloy elements, the content of pearlite in a base body is increased, the pearlite layer sheet thickness and sheet distance are obviously reduced, base body structure grains are fine, a graphite sheet formed through one-time crystallization is fine and disperse,a small number of ferrite base body structures are easily obtained, hardness can be better reduced, material toughness is improved, the metallurgical quality is good, and strength is high.

Owner:武汉机械工艺研究所有限责任公司

Ca- and Sn-containing gold alloy for corrosion-resistant and deformation-resistant 18K rose-bengal gold

The invention discloses a Ca- and Sn-containing gold alloy for corrosion-resistant and deformation-resistant 18K rose-bengal gold. The Ca- and Sn-containing gold alloy comprises the components of, byweight percentage, 0.2-0.4wt.% of Ca, 0.4-0.6wt.% of Hf, 1.5-3.0wt.% of Sn, 0.2-0.4wt.% of Se, 6.0-8.0wt.% of Ag, 74.0-76.0wt.% of Au, and the balance copper. The patent solves the problem that existing 18K rose gold is discolored during use. Through innovation and optimization of alloy components, a development bottleneck of 18K rose gold materials for jewelries is broken through. It can be estimated that implementation and industrialization of the Ca- and Sn-containing gold alloy will bring plentiful and substantial economic gains and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

Economical chloride ion corrosion-resistant steel bar material

InactiveCN113881896AImprove corrosion resistanceStable corrosion resistanceReinforced concreteChloride

The invention relates to the technical field of corrosion-resistant steel bar materials, in particular to an economical chloride ion corrosion-resistant steel bar material, which is characterized by comprising the following components in percentage by weight: 0.04 to 0.08 percent of C, 0.06 to 0.36 percent of Si, 0.10 to 1.20 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.005 percent of S, 4.0 to 5.5 percent of Cr, 0.15 to 1.1 percent of Ni, 0.18 to 0.30 percent of Cu, 0.020 to 0.035 percent of V and the balance of Fe and inevitable impurity elements. According to the economical chloride ion corrosion-resistant steel bar material disclosed by the invention, through optimal arrangement of all alloy elements and optimization of the content ranges and proportions of Cr and Ni, the cost of a steel bar material can be reduced, the service life of a reinforced concrete structure is remarkably prolonged, the use requirements of ocean engineering are met, the highest cost performance is achieved, and large-scale popularization and application are facilitated.

Owner:YANGZHOU UNIV

Miao silver alloy used for nickel-free high-elasticity-modulus jewelry resistant to hydrogen sulfide corrosion and process of Miao silver alloy

The invention discloses a Miao silver alloy used for nickel-free high-elasticity-modulus jewelry resistant to hydrogen sulfide corrosion and a process of the Miao silver alloy. The alloy comprises 0.3wt%-0.5 wt% of B, 2.0 wt%-3.0 wt% of Mg, 0.8 wt%-1.0 wt% of Ge, 1.5 wt%-1.8 wt% of In, 1.2 wt%-1.5 wt% of Y, 4.0 wt%-6.0 wt% of Fe, 40.0 wt%-50.0 wt% of Ag and the balance copper. The material provides a solution of material science for the Miao silver alloy in China, Miao silver products are environment-friendly and do not cause allergies after being machined, and the alloy has excellent corrosion resistance. By means of implementation and industrialization of the material, the product renewal requirement of the jewelry industry in China and the requirement of industry upgrading can be effectively promoted.

Owner:GUANGZHOU YUZHI TECH CO LTD

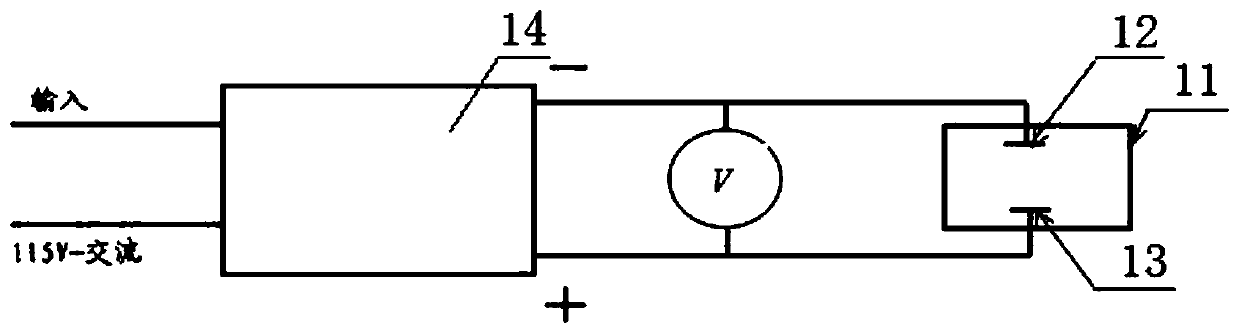

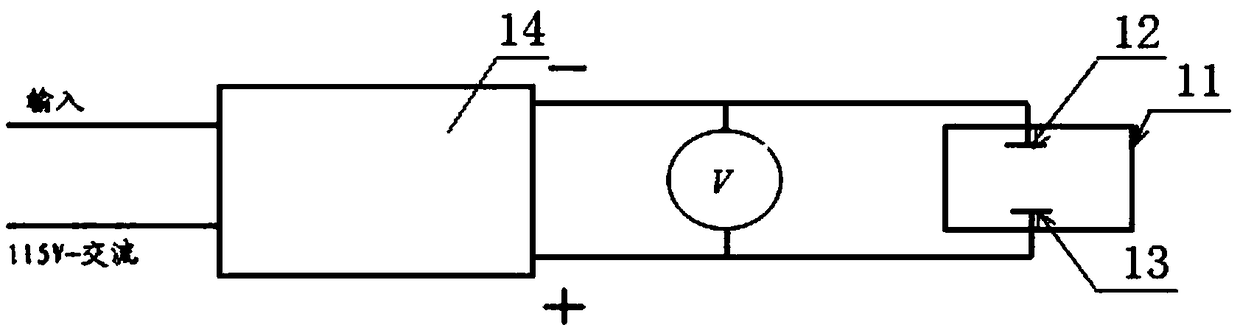

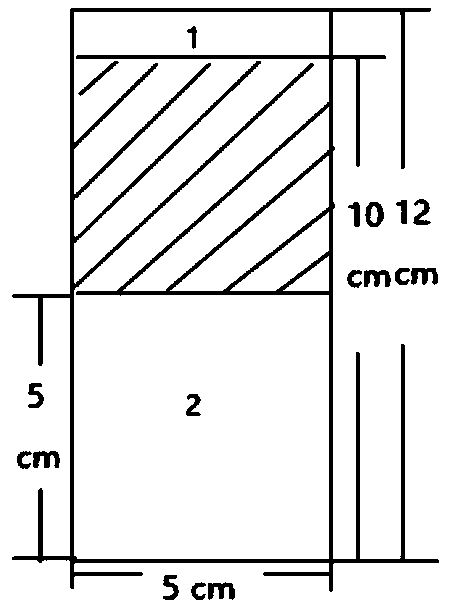

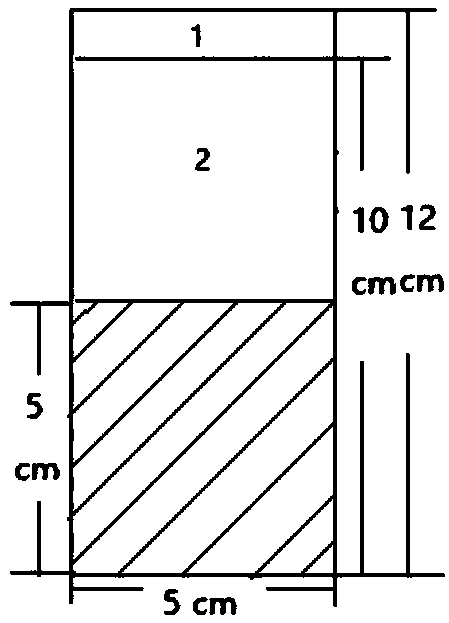

Method for judging the level of metal chromium content on the surface of chrome-plated plate

ActiveCN109030605BStable corrosion resistanceImprove insulation performanceMaterial analysis by electric/magnetic meansElectrolytic agentPlatinum

The invention discloses a method for judging the surface chromium metal content of a chromium-plated plate. The method comprises the following steps that: firstly, selecting a chromium-plated plate specimen; removing a chromium oxidation layer on the surface of the chromium-plated plate specimen; then, taking the chromium-plated plate specimen as an anode and a platinum wire as a cathode, carryingout constant current electrolysis in electrolyte sodium carbonate solution, recording a voltage value, marking voltage at the beginning as E1, along with electrolysis reaction, raising the voltage, subsequently, sharply increasing the voltage, when the voltage hardly changes, finishing electrolysis, finishing electrolyzing all surface metal chromium layers of the chromium-plated plate specimen, and recording voltage E2; and finally, calculating a voltage difference [Delta]E=E2-E1 before and after electrolysis to realize the semi-quantitative analysis of a chromium-plated amount of the surfaceof the chromium-plated plate. By use of the device, the measurement of the surface chromium-plated amount can be carried out on any position of the surface of the chromium-plated plate, and the distribution evenness of the surface metal chromium of the chromium-plated plate can be accurately judged.

Owner:武汉钢铁有限公司

Electrostatically conductive oil-tolerant paint containing rich zinc and silicic acid

InactiveCN1168789CFilm stabilizationEasy constructionElectrically-conductive paintsAlcoholSilicic acid

An antistatic paint is prepared through mixing ethyl n-silicate with absolute alcohol, stirring, alcoholysis reaction, dropping hydrochloric acid diluted by purified water to make pH=2-3, laying aside, adding organic silanamine, stirring, adding zinc powder and stirring. Its advantages are high electrostatic conductivity and corrosion resistance, low cost, fast dry, and high firmness of film.

Owner:黄观明 +1

Trivalent chromium color passivation solution, preparation method and use method thereof

ActiveCN104498923BQuality improvementStable passivation working fluidMetallic material coating processesPorositySalt spray test

The invention provides a colorful trivalent chromium passivation liquid. A plurality of raw materials are dissolved in deionized water to form the passivation liquid. The passivation liquid comprises the following components by a ratio: 5-9 g / L chromium sulfate hexahydrate, 2-4 g / L cobalt sulfate heptahydrate, 4-8 g / L sodium chlorate, 2-3 g / L ammonium fluoride, 1-2 g / L of nitric acid, 2-3 g / L citric acid, and the balance of water. The resulting passive film has good corrosion resistance, the time can be up to 120 hours or more in a salt spray test, the surface has no any white rust or white spots, the porosity is low, and a blocking agent does not need to be used for treating.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

White low-density high-hardness corrosion-resistant low-gold-content gold alloy for Miao people and process of gold alloy

The invention discloses a white low-density high-hardness corrosion-resistant low-gold-content gold alloy for Miao people and a process of the gold alloy. The gold alloy comprises 0.4-0.8 wt.% of Li,15.0-18.0 wt.% of Al, 10.0-12.0 wt.% of In, 0.5-0.8 wt.% of B, 0.2-0.3 wt.% of Y, 4.0-6.0 wt.% of Ge, 29.0-30.0 wt.% of Au and the balance Cu. The material provides a lightweight option for the gold alloy of Miao people in China. Obtained products have not only excellent white appearance but also good corrosion resistance. The implementation and industrialization of the material can effectively boost the demand of product update and industry upgrade in the jewelry industry in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

Method for judging surface chromium metal content of chromium-plated plate

ActiveCN109030605AThe amount of chrome platingEasy to measureMaterial analysis by electric/magnetic meansElectrolysisPt element

The invention discloses a method for judging the surface chromium metal content of a chromium-plated plate. The method comprises the following steps that: firstly, selecting a chromium-plated plate specimen; removing a chromium oxidation layer on the surface of the chromium-plated plate specimen; then, taking the chromium-plated plate specimen as an anode and a platinum wire as a cathode, carryingout constant current electrolysis in electrolyte sodium carbonate solution, recording a voltage value, marking voltage at the beginning as E1, along with electrolysis reaction, raising the voltage, subsequently, sharply increasing the voltage, when the voltage hardly changes, finishing electrolysis, finishing electrolyzing all surface metal chromium layers of the chromium-plated plate specimen, and recording voltage E2; and finally, calculating a voltage difference [Delta]E=E2-E1 before and after electrolysis to realize the semi-quantitative analysis of a chromium-plated amount of the surfaceof the chromium-plated plate. By use of the device, the measurement of the surface chromium-plated amount can be carried out on any position of the surface of the chromium-plated plate, and the distribution evenness of the surface metal chromium of the chromium-plated plate can be accurately judged.

Owner:武汉钢铁有限公司

Aluminum and aluminum alloy passivation solution, preparation method and application method thereof

ActiveCN104451634BAvoid the problem of poor corrosion resistanceQuality improvementMetallic material coating processesVoid ratioSodium fluoride

The invention provides an aluminum and aluminum alloy passivation solution, preparation method and using method thereof; the raw material ratios of the passivation solution are as follows: 3-5g / L of zinc chromate, 0.5-1g / L of cobaltous sulfate, 2-3g / L of zirconium sulfate, 0.5-1.5g / L of sodium fluoride, 2-4g / L of nitric acid, 1-2g / L of citric acid, and the rest amount is water. A passivation working solution (bath solution) which is prepared by diluting the passivation solution is stable, low concentration, fast in passivation speed, low void ratio of the obtained passivation film, is able to form a yellow chromate film layer on surface of the aluminum product, has an excellent anti-corrosion property, and is able to greatly increase the paint or coating layer adhesive force on the work piece. The property of the formed passivation film for resisting neutral salt mist is more than 120 hours.

Owner:HUNAN JINYU CHEM

Ba and Ge containing gold alloy for corrosion-resisting and deformation-resisting 10K rose red gold

The invention discloses a Ba and Ge containing gold alloy for corrosion-resisting and deformation-resisting 10K rose red gold. According to the weight percent, the alloy comprises components including0.3 wt.%-0.5 wt.% of Ba, 0.2 wt.%-0.4 wt.% of Zr, 1.0 wt.%-1.5 wt.% of Ge, 0.3 wt.%-0.5 wt.% of W, 20.0 wt.%-25.0 wt.% of Ag, 40.0 wt.%-42.0 wt.% of Au and the balance Cu. The Ba and Ge containing gold alloy avoids the phenomenon that current 10K rose gold fades in the usage process. Through alloy component innovation and optimization, the development bottleneck of jewelry 10K rose gold materialsis broken through. It can be predicted that abundant economic gains and social benefits can be obtained due to material implementation and industrialization.

Owner:GUANGZHOU YUZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com