Economical chloride ion corrosion-resistant steel bar material

An economical ion corrosion technology, applied in the field of corrosion-resistant steel bars, can solve the problems of high cost of corrosion-resistant steel bars, achieve stable corrosion resistance, reduce maintenance costs, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

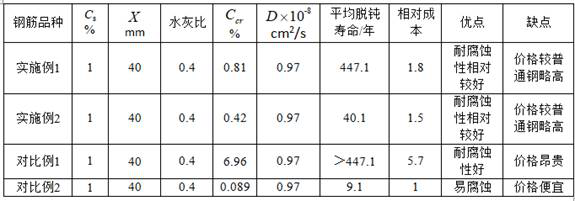

[0050] In Example 2, the mass ratio of Cr to Ni is 33.7, which is not in the range of (5-10):1, and the depassivation life is shorter than that of Example 1, but when the thickness of the protective layer reaches 65mm, it is predicted that the depassivation life has already Reaching more than 100 years, the relative cost is only about 1.5 times that of ordinary steel bars, and it still has a good performance-cost effect.

[0051] By adjusting the thickness of the protective layer to 65mm, the corrosion-resistant steel bar of the present invention can have a service life of 100 years. However, in order not to make the thickness of the protective layer too large (when the protective layer is thicker, the cracks of the structure are difficult to control, and the bearing capacity of the structure will also be reduced), the present invention optimizes the content of the corrosion-resistant alloy elements Cr and Ni to meet the service life requirements.

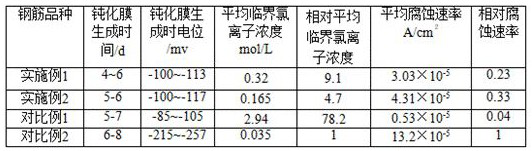

[0052] It can be seen from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com