Trivalent chromium color passivation solution, preparation method and use method thereof

A passivation solution, trivalent chromium technology, applied in metal material coating process and other directions, can solve the problems of large porosity, short service life and poor corrosion resistance of passivation film, and achieve low porosity and stable corrosion resistance. , The effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

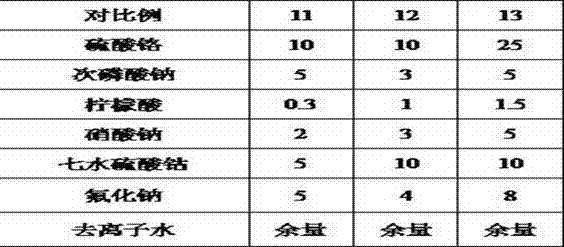

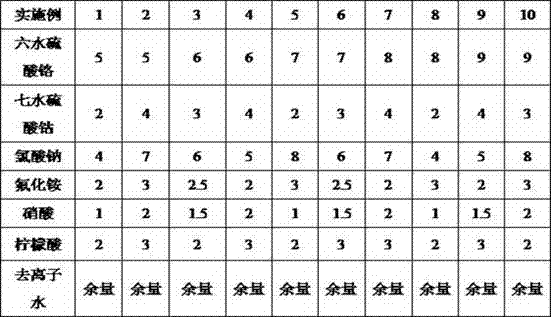

[0051] Examples 1-10 respectively provide the composition of the trivalent chromium color passivation solution of the present invention, specifically as listed in Table 1, wherein the unit of the ingredients is g / L.

[0052] Table 1 embodiment 1-10 formula composition

[0053]

[0054] The preparation method of the passivation solution of the above examples 1-10 is as follows: taking the preparation of 1000ml passivation solution as an example, the following steps are successively included: add 600ml deionized water into a 2000ml beaker, add nitric acid and citric acid, stir until dissolved, and mix well; Add chromium sulfate hexahydrate, cobalt sulfate heptahydrate, and sodium chlorate, and stir until completely dissolved; add ammonium fluoride, and stir until completely dissolved; add deionized water until the total volume of the solution is 1000ml, and stir well to obtain the third compound of the present invention. Chromium color passivation solution.

Embodiment 14

[0067] With the trivalent chromium color passivation solution 100ml of embodiment 6, at 25 ℃, carry out passivation treatment to 100 above-mentioned test pieces successively, passivation time is 60 seconds, after the test piece after passivation is washed through 60 ℃ of deionized water, Dry with hot air at 60°C. It was observed that the passivation status of each test piece was better, and the color was consistent. The 10th, 30th, 50th, 70th, and 100th piece were taken for neutral salt spray corrosion test, and the passivation effect listed in Table 3 could be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com