Method for judging the level of metal chromium content on the surface of chrome-plated plate

A technology of surface metal and determination method, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to measure the amount of chrome plating on the surface well, pollute the environment, and tedious operation, and achieve convenient and fast measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

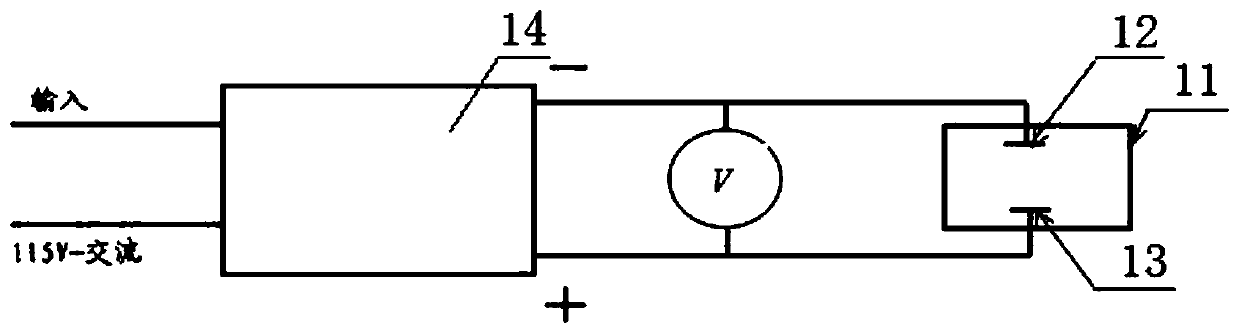

[0045] Judgment of the amount of chrome plating on the front and back of the chrome-plated plate

[0046] Cut the chrome-plated plate into 12cm-long and 5cm-wide chrome-plated plate samples, soak the chrome-plated plate sample in 100mL 90℃ 300g / L NaOH solution for 20min, take out the chrome-plated plate sample, rinse it three times, dry it, and remove the chrome-plated plate Chromium oxide layer on the surface of the sample.

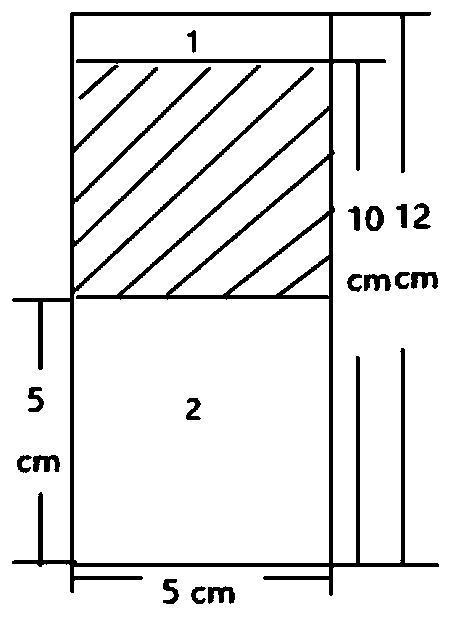

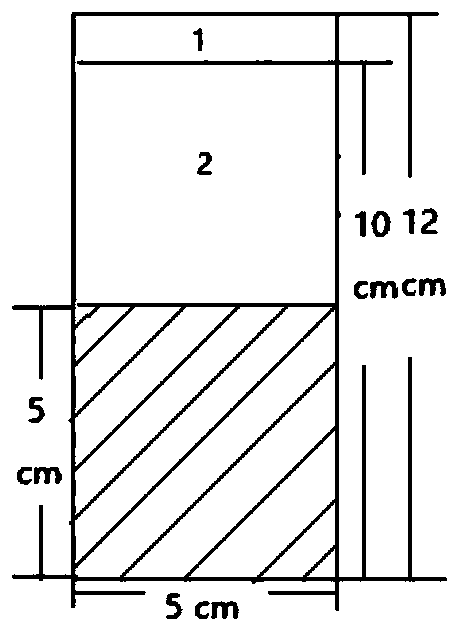

[0047] The two sides of the chrome-plated plate sample are respectively recorded as a-side and b-side, and the jump potential ΔE of the chrome-plated plate in the range of 5cm×5cm is measured on both sides. Surface a starts from the bottom of the chrome-plated plate sample, and takes the range of 5cm in length and 5cm in width as the area to be measured. The surface of the chrome-plated plate sample is coated with silicone rubber within the range of length greater than 5cm and less than 10cm from the bottom, and sealed. Among them, there is a distance o...

Embodiment 2

[0052] The determination of the amount of chrome plating in different areas on the same surface of the chrome-plated plate.

[0053] Cut the chrome-plated plate into 7cm×5cm chrome-plated plate samples, soak the chrome-plated plate sample in 100mL 90℃300g / LNaOH solution for 20min, take out the chrome-plated plate sample, rinse it three times and dry it, then remove the chrome-plated plate sample Surface chromium oxide layer.

[0054] In the 2cm area from the top of the chrome-plated plate sample, no silicone rubber is used for conductivity. Take an area of 1cm×1cm from the top, middle and bottom of the board for testing, and seal other parts with silicone rubber, see image 3 , where 1, 2, and 3 are the areas of the sample to be tested, and 4 is the connection between the electrolytic clamp and the sample. The electrolysis reaction proceeds sequentially from the bottom to the top. Specifically:

[0055] 1) Soak the area to be tested at the bottom of the chrome-plated pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com