Preparation method for superhydrophobic superoleophilic straw fiber

A technology of straw fiber and super-oleophilicity, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of weak adsorption capacity of inorganic mineral oil-absorbing materials and high cost of organic synthetic oil-absorbing materials, and achieve selectivity Good adsorption performance, excellent oil absorption performance, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

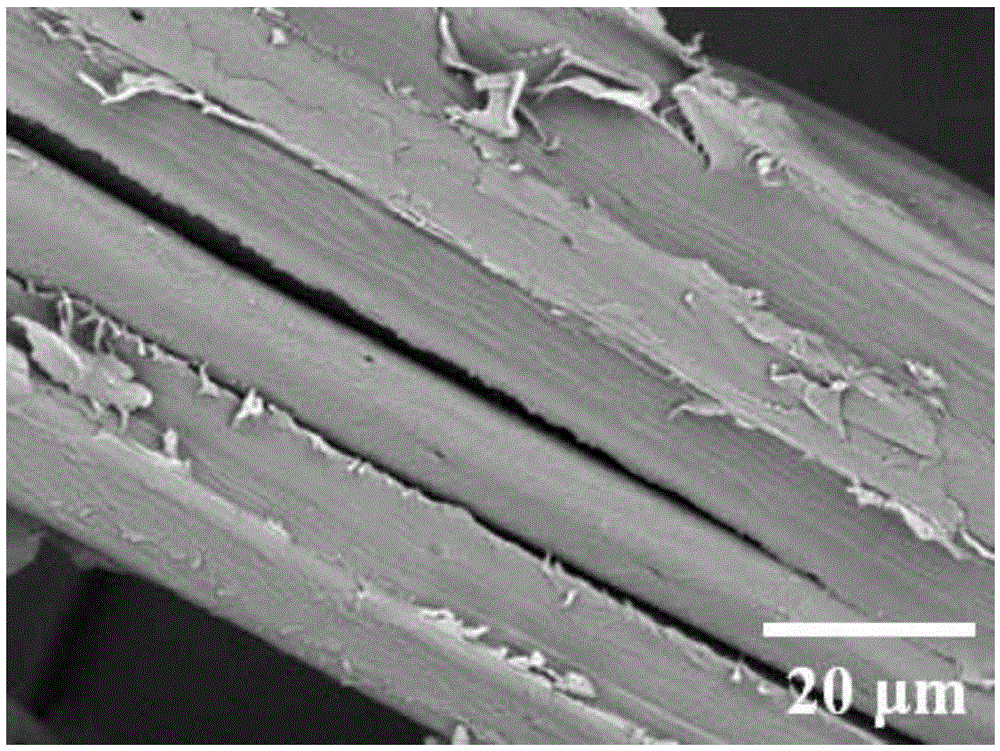

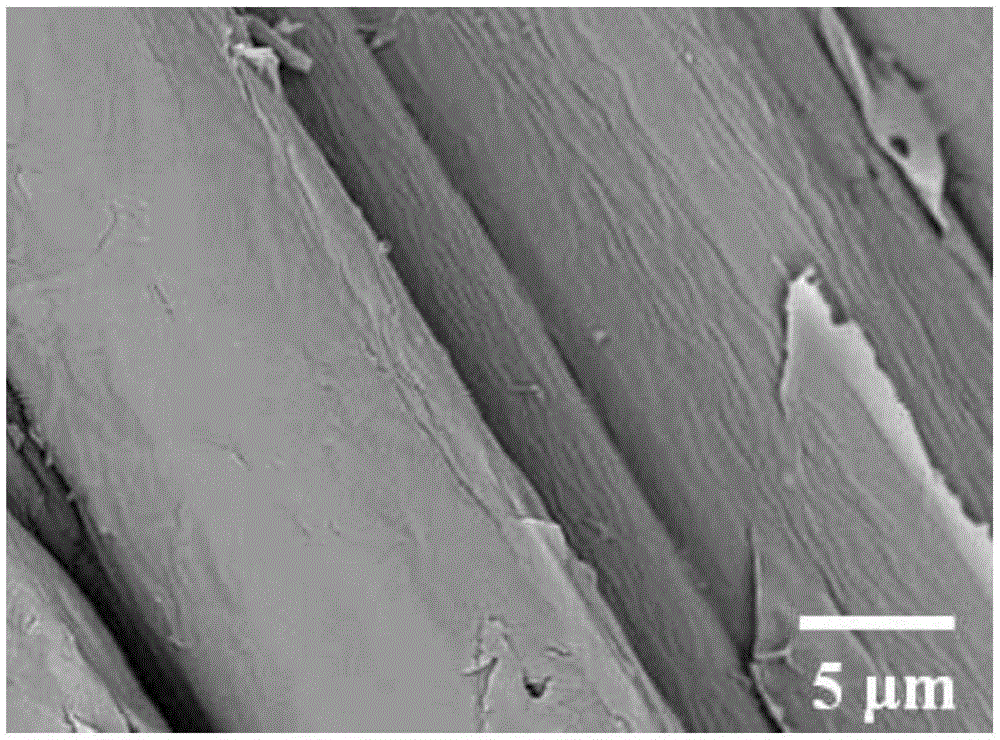

[0021] Specific Embodiments 1. In this embodiment, taking corn stalk fiber as an example, a method for preparing superhydrophobic and super lipophilic straw fiber is carried out according to the following steps:

[0022] 1. After drying the discarded straw, put it into a pulverizer to pulverize it, pass through a 60-mesh sieve, immerse the straw fiber in a sodium hydroxide solution with a mass fraction of 5%, and pretreat it for 10 hours under the condition of magnetic stirring. The pure water was washed repeatedly until the pH was close to neutral, and dried in an oven at 40°C to constant weight to obtain straw fibers.

[0023] 2. Measure 80mL of absolute ethanol, 2ml of ultrapure water, 2ml of tetraethyl orthosilicate, and 1ml of ammonia water into a 250ml beaker in turn, and stir on a magnetic stirrer at room temperature, then add 0.3g of straw fiber and continue stirring After 2 hours, the straw fibers were filtered out with a nylon filter, washed with ultrapure water and ...

specific Embodiment approach 2

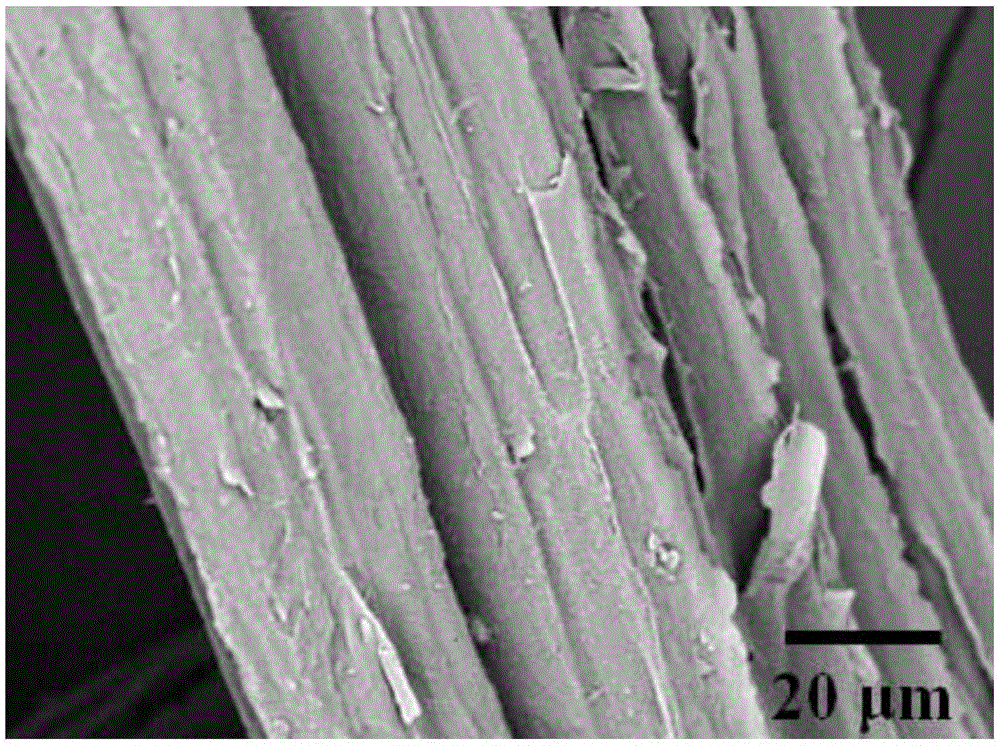

[0031] Specific implementation mode 2. In this implementation mode, taking corn stalk fiber as an example, a method for preparing superhydrophobic and super lipophilic straw fiber is carried out according to the following steps:

[0032] 1. After drying the discarded straw, put it into a pulverizer for crushing, pass through an 80-mesh sieve, immerse the straw fiber in a sodium hydroxide solution with a mass fraction of 7%, pretreat for 14 hours under magnetic stirring conditions, and use an ultra- Wash with pure water repeatedly until the pH is close to neutral, and dry in an oven at 50°C until constant weight.

[0033] 2. Measure 120mL of absolute ethanol, 5mL of ultrapure water, 5mL of tetraethyl orthosilicate, and 2mL of ammonia water into a 250ml beaker in turn, stir magnetically at room temperature, then add 0.5g of straw fiber, continue to stir for 4 hours, and use a nylon filter to Straw fibers were filtered out, washed with ultrapure water and absolute ethanol in sequ...

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the reaction temperature in step 3 is 70°C. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com