Package of multiple oil wipes

A technology for wipes and products, applied in the direction of layered products, cosmetic preparations, packaging, etc., can solve complex and expensive problems, achieve the effect of improving texture and feeling, reducing stiffness, and reducing surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

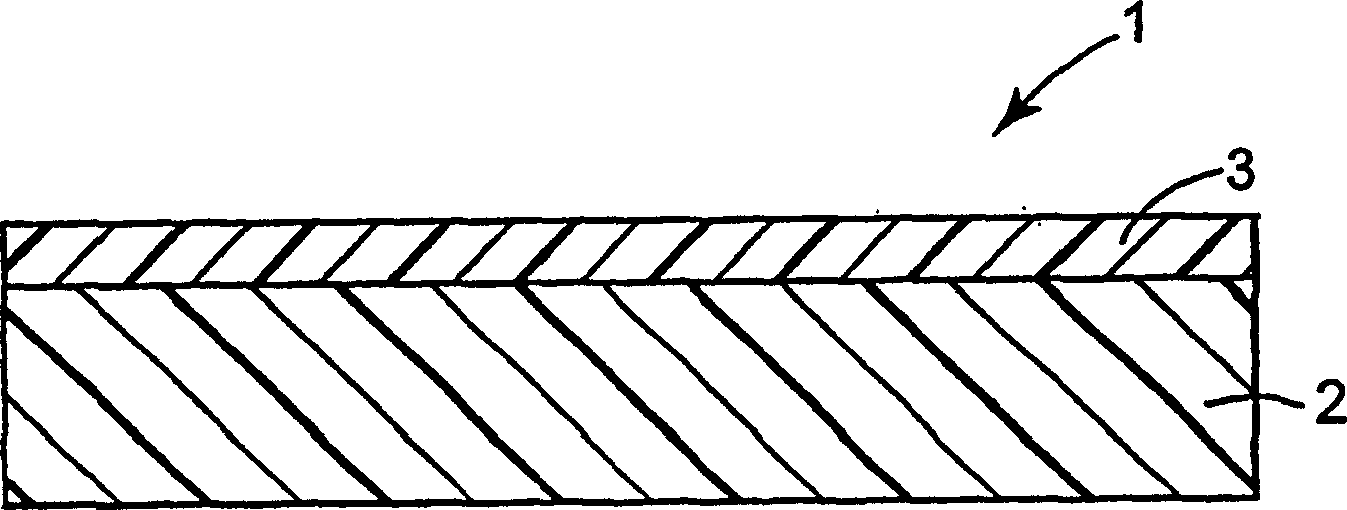

[0065]Facial wipes were prepared by thermal lamination of the microporous film described above to a 30 g / m2 polypropylene meltblown microfiber nonwoven. Can be according to U.S. Pat. The melt-blown hydrophilic fabrics used in the present invention were prepared as described in . In particular, as in Wente's "Superfine Thermoplastic Fibers", "Superfine Thermoplastic Fibers" 48 INDUS.ENG'G CHEM.1342 (1956) "Industrial Engineering Chemistry" Vol. 48, p1342 (1956) or The method described in Wente et al.'s "Manufacture of Superfine Organic Fibers" (MANUFACTURE OF SUPERFINE ORGANIC FIBERS "Navy Research Laboratory" No. 4364 report) (Naval Research Laboratories No.4364, 1954) can be used to prepare this Invented non-woven fabrics. However, since the surfactants used as melt additives in the present invention may be thermally unstable, it is preferable to add the surfactants to the polymer melt just before it is extruded from the die, as described in U.S. Patent No. 4,933,229 (Insl...

Embodiment 2

[0067] Facial wipes were made by heat laminating the microporous film described above to a 34 g / m 2 spun nonwoven made of 70% rayon fiber and 30% polypropylene fibers. The nonwoven side of the laminate was impregnated with a water / ethanol (15%) mixture by spray coating. The microporous film was laminated to the nonwoven using a 5% circular, point-bonded emboss at 66°C and a nip pressure of 3.5 kg / cm2. The resulting laminate is capable of functioning as an oil and sweat wet facial wipe where the user can use the microporous film side to degrease the skin and turn the wipe over to use the nonwoven side to wipe off sweat and dirt. The nonwoven fabric can be loaded with dry or wet fragrances, cleansers, sensates, actives, etc. for added functionality.

Embodiment 3

[0069] Facial wipes were made according to Example 1 using the following dry ingredients at 9% solids in isopropanol:

[0070] 34.06% Sericite TKC (potassium aluminum silicate)

[0071] 17.03% Talc JA-46R (hydrous magnesium silicate)

[0072] 8.55% Urethane D-400 Powder (Hexamethylene Diisocyanate / Trimethylol Caprolactone)

[0073] 0.20% red Tarox iron oxide pigment

[0074] 0.40% Yellow Tarox Iron Oxide Pigment

[0075] 0.02% Black Tarox Iron Oxide Pigment

[0076] 39.74% Rheodole Super SP-L10 (Sorbitan monolauryl)

[0077] The coated microporous membranes were allowed to air dry for 24 hours prior to testing. The dry powder weight on the film was 2.50 g / m2. The resulting wipe can be used to absorb sebum and provide a powder to the skin to remove shine. Powders can be formulated to provide additional cosmetic and active ingredients, including sebum absorption or control agents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com