Method for preparing citrus fibers through ultrasonic treatment

A citrus fiber and ultrasonic technology, which is applied in the direction of food ultrasonic treatment, the function of food ingredients, and food ingredients as thickeners, etc., can solve the problems of difficult dissolution, low cellulose reactivity, and poor uniformity of chemical reactions, etc., and achieve low cost , broaden the scope of application, good water holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

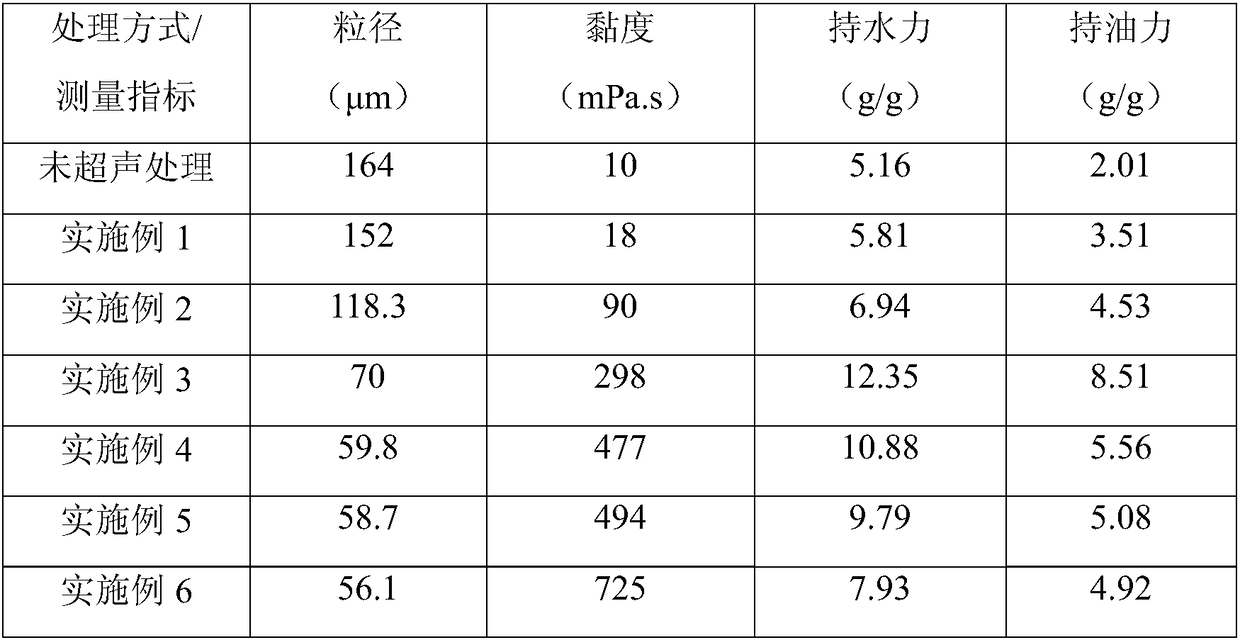

Embodiment 1

[0036] The citrus fiber slag (residue after extracting high-ester pectin, low-ester pectin and amidated pectin from citrus peels) was pulverized twice with a pulverizer with a power of 550w, passed through an 80-mesh sieve, and deionized Water is prepared into a solution with a mass concentration of 0.1%. After stirring at 5000 rpm for 0.5h, use ultrasonic power of 250w for 1min, and adjust the pH to 3.0 with sodium hydroxide while fully stirring, and bathe in a water bath at 45°C for 1h. , to measure the particle size and viscosity of the solution. Add 60% absolute ethanol to the remaining citrus fiber solution and let it stand still, then centrifuge for 10 minutes to remove the supernatant, and dry the solid precipitate at 45° C. to obtain the final citrus fiber powder. Determination of its water holding capacity and oil holding capacity.

[0037] The measured water holding capacity of the citrus fiber is 5.81g / g, the oil holding capacity is 3.51g / g, the viscosity is 18.0mP...

Embodiment 2

[0039] The citrus fiber slag (residue after extracting high-ester pectin, low-ester pectin and amidated pectin from citrus peels) was ground 3 times with a pulverizer with a power of 550w, passed through a 90-mesh sieve, and deionized Water is prepared into a solution with a mass concentration of 0.5%. After stirring at 5000 rpm for 1 hour, use an ultrasonic wave with an ultrasonic power of 350w for 3 minutes, and adjust the pH to 6.0 with sodium hydroxide while fully stirring, and bathe in a water bath at 50°C for 1.5 hours. , to measure the particle size and viscosity of the solution. Add 75% ethanol aqueous solution with a volume fraction of 95% to the remaining citrus fiber solution, let it stand, centrifuge for 15 minutes to remove the supernatant, and dry the solid precipitate at 70° C. to obtain the final citrus fiber powder. Determination of its water holding capacity and oil holding capacity.

[0040] The measured water holding capacity of the citrus fiber is 6.94g / g...

Embodiment 3

[0042] The citrus fiber slag (residue after extracting high-ester pectin, low-ester pectin and amidated pectin from citrus peels) was pulverized 5 times with a pulverizer with a power of 550w, passed through a 120-mesh sieve, and deionized Water is prepared into a solution with a mass concentration of 1.0%. After stirring at 5000 rpm for 2 hours, use an ultrasonic power of 450w for 5 minutes, and adjust the pH to 7.0 with sodium hydroxide while fully stirring, and bathe in a water bath at 60°C for 2 hours. Measure the particle size and viscosity of the solution. Add 70% ethanol aqueous solution with a volume fraction of 95% to the remaining citrus fiber solution, let stand, centrifuge for 20 min to remove the supernatant, and dry the solid precipitate at 60° C. to obtain the final citrus fiber powder. Determination of its water holding capacity and oil holding capacity.

[0043] The measured water holding capacity of the citrus fiber is 12.35g / g, the oil holding capacity is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water holding capacity | aaaaa | aaaaa |

| Oil holding power | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com