Modified natural plant fiber oil absorbent and preparation and application methods thereof

A natural plant fiber and oil-absorbing agent technology, applied in the direction of plant fiber, fiber treatment, separation methods, etc., can solve the problems of moisture, poor buoyancy, restrictions, etc., and achieve the effect of no secondary pollution, excellent oil absorption performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One aspect of the embodiments of the present invention provides a method for preparing a modified natural plant fiber oil-absorbing agent, which includes:

[0030] Provide natural plant fiber base material;

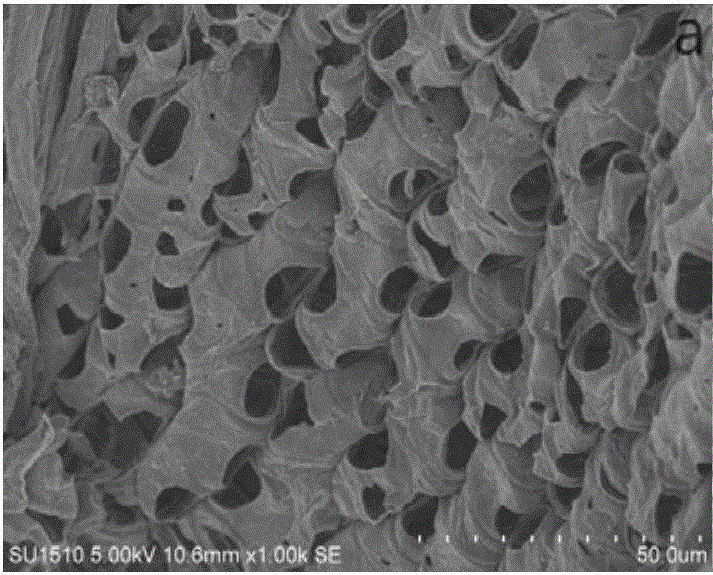

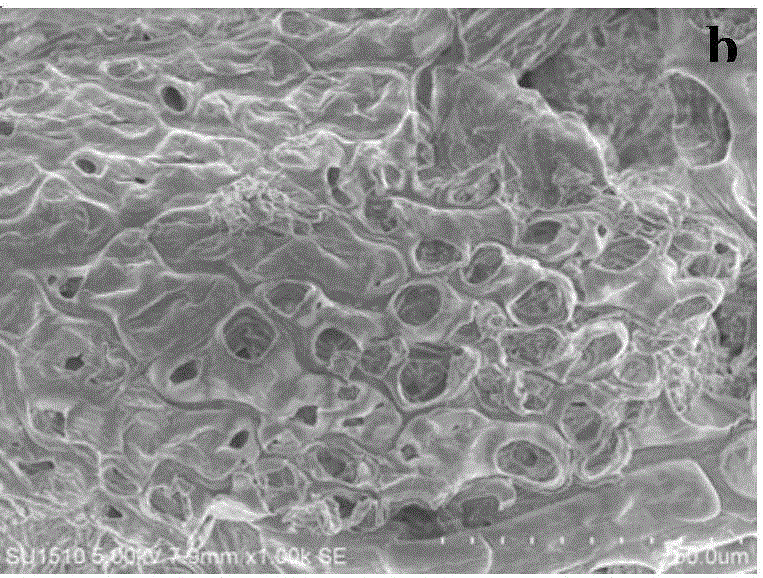

[0031] Physically modifying the natural plant fiber substrate, at least forming a hydrophobic natural polymer film on the surface of the natural plant fiber substrate, to obtain the modified natural plant fiber oil-absorbing agent, the hydrophobic natural polymer The membrane has a multi-level nano-microstructure.

[0032] As one of the preferred embodiments, the physical modification at least includes the steps of crushing and grinding, beating, drying, first impregnation and second impregnation in sequence.

[0033] In some more typical embodiments of the present invention, the preparation method of the modified natural plant fiber oil-absorbing agent may include the following steps:

[0034] (1) Crushing and grinding: one or more natural plant fibers are groun...

Embodiment 1

[0052] (1) Crushing and grinding: 100 g of natural straw fibrils were ground and pulverized at room temperature, and screened with a 50-mesh sieve to obtain 95 g of natural straw fibrils for later use.

[0053] (2) Beating: adopt the plant fiber dry pulp made of 95g of natural straw fibrils, add 1000mL of hot water to mix, help the fibers to moisten, beat under the condition of controlling the pulp concentration to be 8.7%, and the beating time 60min to obtain natural straw fibril pulp.

[0054] (3) Drying: Dry the natural straw fibril pulp at 105° C. for 12 hours to constant weight, take it out and seal it, and obtain 80 g of natural straw fibrils for use.

[0055] (4) First impregnation: Add 5 g of sodium alginate (with a high molecular weight of 500,000 Da) into 200 mL of water, mix evenly and stir for 40 min to fully dissolve it. Soak 80 g of natural straw fibrils in the mixed solution for 30 minutes, take them out, squeeze them dry, and dry them in a vacuum oven at 120° ...

Embodiment 2

[0058] (1) Crushing and grinding: 100 g of natural corn stalk fibrils were ground and pulverized at room temperature, and sieved with an 80-mesh sieve to obtain 90 g of natural corn stalk fibrils for later use.

[0059] (2) Beating: adopt the plant fiber dry pulp made of 90g of natural corn stalk fibrils, add 900mL of hot water to mix, help the fibers to moisten and expand, beat under the condition of controlling the slurry concentration to 9%, and the beating time 90min to obtain natural corn stalk fibril pulp.

[0060] (3) Drying: Dry the natural corn stalk fibril pulp at 125° C. for 18 hours to constant weight, take it out and seal it, and obtain 80 g of natural corn stalk fibrils for later use.

[0061] (4) First impregnation: Add 5 g of methylcellulose (high molecular weight 200,000 Da) into 300 mL of water, mix evenly and stir for 60 min to fully dissolve. Soak 80 g of natural corn stalk fibrils in the mixed solution for 60 minutes, take them out, squeeze them dry, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorptive capacity | aaaaa | aaaaa |

| Absorptive capacity | aaaaa | aaaaa |

| Absorptive capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com