Refrigerator oil composition

A technique for refrigerating machine oils and compositions, applied in lubricating compositions and the petroleum industry, etc., capable of solving the adverse effects of refrigerating machine oils on thermal-chemical stability and low-temperature performance, limited effect of dewaxing dewaxing of mineral oils, capillary and expansion valve blockages To improve thermal/chemical stability and low-temperature performance, achieve good pour point depressing effect, and shorten service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

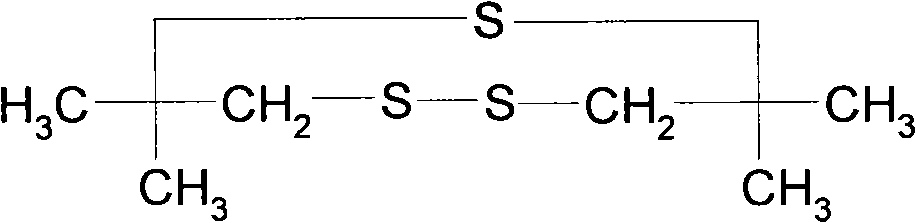

[0035] Additive 1: The amount added is based on the total weight of the base oil

[0036]

[0037] Add additive 1 to base oil 1 and base oil 2 respectively, and compare the implementation effect:

[0038] ANSI / ASHARE 97 refrigerating machine oil seal tube test method was used to investigate its thermal / chemical stability. The sample and refrigerant were 1:1 (mass), and then steel, aluminum, and copper catalysts were added, and sealed at 175°C for 14 days. , Observe the color and appearance of the solution and catalyst to evaluate.

[0039] Thermal / Chemical Stability

Embodiment 2~4

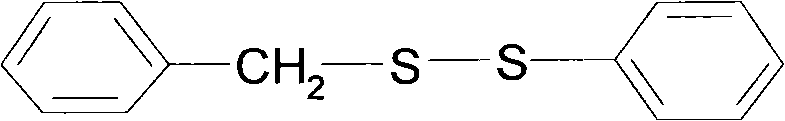

[0042] Additives: the amount added is based on the total weight of the base oil

[0043]

[0044] Implementation Effect:

[0045]

Embodiment 5~8

[0047] Example 5

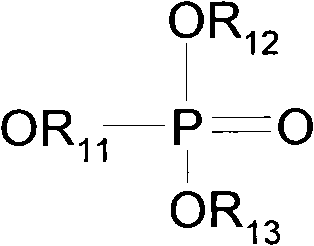

[0048] Additives: the amount added is based on the total weight of the base oil

[0049]

[0050] Implementation Effect:

[0051] Thermal / Chemical Stability

[0052] Judging from the comparative effects of the above examples and comparative examples, the refrigerating machine oil with a higher refining depth has better thermal-chemical stability and low-temperature performance, and will not be carbonized in the refrigeration cycle, and corrosion and blockage such as acid or sludge will not occur At the same time, the compressor will not stay or produce flocs at low temperatures, and prevent the capillary and expansion valve from being blocked, thereby improving the cooling efficiency of the air conditioner and ensuring long-term stable operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com