High-purity and environment-friendly iso-paraffin solvent oil and application thereof

A technology for isoparaffin solvent oil and isoparaffin, which can be applied in the application, treatment of hydrocarbon oil, hydrocarbon oil treatment products, etc., and can solve the problems of purity and performance gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

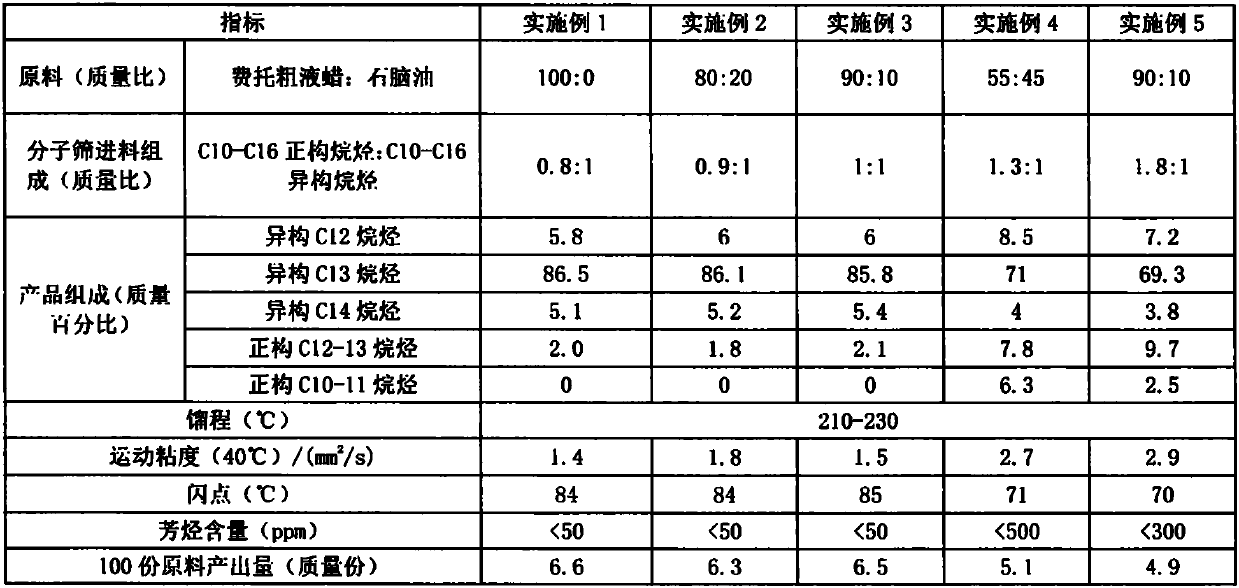

Embodiment 1

[0035] The raw material used is: Fischer-Tropsch crude liquid wax of Fischer-Tropsch synthesis process. After the raw material pretreatment unit, lightness removal, weight removal, and fractional distillation are carried out to obtain light white oil and industrial white oil.

[0036] The material after removing light and heavy components is used as molecular sieve feed. The molecular sieve feed is mainly C10-C16 normal paraffins and C10-C16 isoparaffins, and the mass ratio of the two is 0.8:1. Using the molecular sieve adsorption dewaxing process, the simulated moving bed process is adopted in the fixed bed equipped with solid adsorbent, and the selective adsorption and desorption are continuously carried out under the conditions of isothermal, isobaric and liquid phase, and normal alkanes and non-normal alkanes are separated. Paraffins are separated.

[0037] The adsorption separation part is mainly composed of an adsorption chamber equipped with 5A molecular sieve, a rota...

Embodiment 2

[0040] The raw materials used are: the mass ratio of Fischer-Tropsch crude liquid wax and naphtha in the Fischer-Tropsch synthesis process is 80:20. After the raw material pretreatment unit, lightness removal, weight removal, and fractional distillation are carried out to obtain light white oil and industrial white oil.

[0041] The material after removing light and heavy components is used as molecular sieve feed. The molecular sieve feed is mainly C10-C16 normal paraffins and C10-C16 isoparaffins, and the mass ratio of the two is 0.9:1.

[0042] All the other operating processes are the same as in Example 1.

[0043] In terms of parts by mass, the output of IP80 is 6.3 parts per 100 raw materials.

Embodiment 3

[0045] The raw materials used are: the mass ratio of Fischer-Tropsch crude liquid wax and naphtha in the Fischer-Tropsch synthesis process is 90:10. After the raw material pretreatment unit, lightness removal, weight removal, and fractional distillation are carried out to obtain light white oil and industrial white oil.

[0046] The material after removing light and heavy components is used as molecular sieve feed. The molecular sieve feed is mainly C10-C16 normal paraffins and C10-C16 isoparaffins, and the mass ratio of the two is 1:1.

[0047] All the other operating processes are the same as in Example 1.

[0048] In terms of parts by mass, the output of IP80 is 6.5 parts per 100 raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com