Method for preparing oil absorption material by adopting straws as base materials

An oil-absorbing material and substrate technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc. Short pretreatment time and other problems, to achieve the effect of low density, good oil retention effect, and improved oil absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

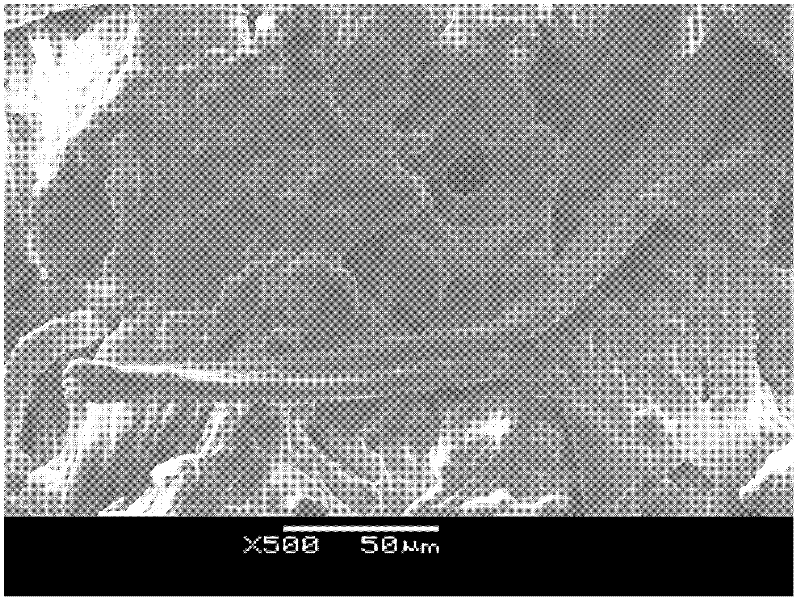

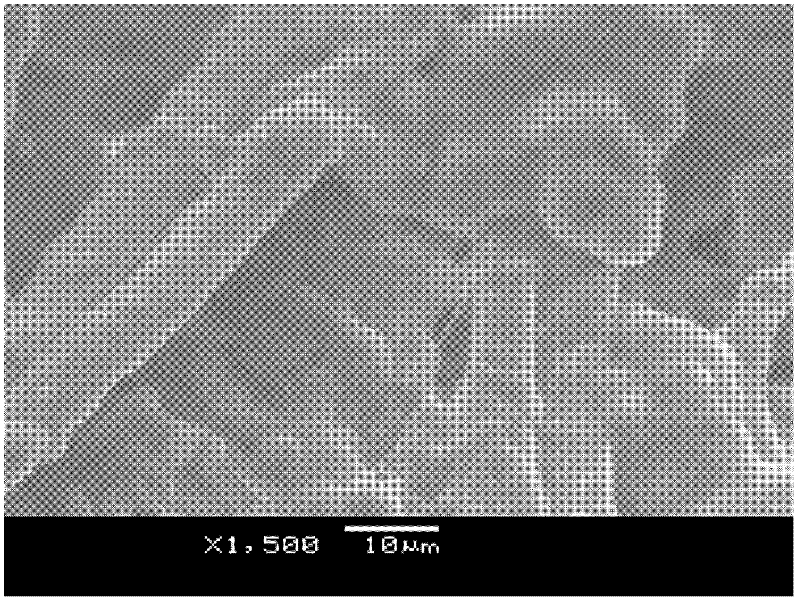

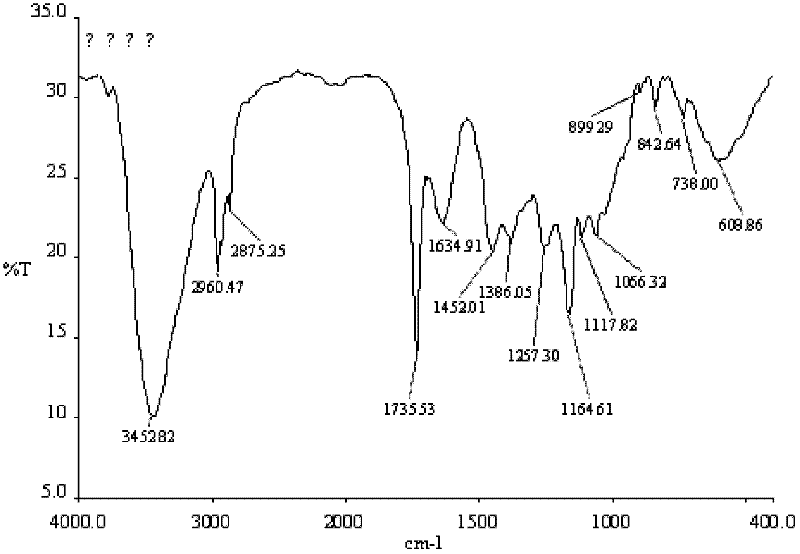

Image

Examples

Embodiment 1

[0054] (1) Peel off the outer skin of 50 g of corn stalks, wash, dry, pulverize and sieve with a universal grinder to make straw fragments. Put straw fragments into a 500mL three-necked flask, add 150mL of 10w% sodium hydroxide solution, heat and stir, cook and react at 85°C for 3h, neutralize with 9.5w% hydrochloric acid to pH 7, wash with water three times, filter , dried to constant weight to obtain straw powder, and set aside;

[0055] (2) Weigh 3g of the treated straw powder, add 120mL of deionized water and stir to make it uniformly dispersed, inject nitrogen, stir and heat up to 40°C;

[0056] (3) adding 0.18g initiator potassium persulfate to the reaction system of step (2) to initiate 30min;

[0057] (4) The temperature of the reaction system in step (3) was raised to 65° C., 9 g of butyl acrylate monomer was added, and after constant temperature reaction for 1 hour, 0.12 g of 1,2-ethylene glycol dimethacrylate crosslinking agent was added, and continued Stop after ...

Embodiment 2

[0063] (1) Peel off the outer skin of corn stalks, wash, dry to constant weight, and pulverize with a universal grinder to make straw fragments. Take 50g of straw fragments and put them into a stirred 500mL three-neck flask, add 150mL of 10w% sodium hydroxide solution, irradiate for 10min under the conditions of microwave radiation power of 800W, and radiation temperature control of 90°C, dilute with 9.5w% neutralize with hydrochloric acid to pH 7, wash with water three times, filter, dry to constant weight to obtain straw powder, and set aside;

[0064] (2) Weigh 3 g of the treated straw powder, add 150 mL of water, stir to disperse the powder evenly, and pass nitrogen gas. Stir and heat up to 40°C;

[0065] (3) adding 0.20g initiator ammonium persulfate to the reaction system of step (2) to initiate 30min;

[0066] (4) The temperature of the reaction system in step (3) was raised to 65° C., and 12 g of lauryl acrylate monomer was added. After reacting for 1 hour, 0.16 g of...

Embodiment 3

[0071] (1) Wash 50 g of corn stalks, dry them, pulverize them with a universal grinder, and sieve them to make straw fragments. In a stirred 500mL three-neck flask, add 150mL of 10w% sodium hydroxide solution, heat and stir, cook and react at 85°C for 3h, neutralize with 9.5w% hydrochloric acid to pH 7, wash with water three times, filter , dried to a constant weight to obtain straw powder, and set aside.

[0072] (2) Weigh 3 g of the treated straw powder, add 120 mL of deionized water and stir to make it uniformly dispersed, inject nitrogen gas, and stir to raise the temperature to 40°C.

[0073] (3) Add 0.30g initiator potassium persulfate to the reaction system of step (2) and initiate 30min;

[0074] (4) The temperature of the reaction system in step (3) was raised to 70° C., 9 g of lauryl methacrylate monomer was added, and after constant temperature reaction for 1 hour, 0.20 g of 1,4-butanediol diacrylate crosslinking agent was added, and continued The reaction was sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com