Spiral groove rotary sealing ring with porous end surface for vehicle

A technology of rotating sealing ring and spiral groove, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of rotating seal failure and the overall failure of traditional devices, so as to reduce friction and wear, reduce the degree of contact, and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

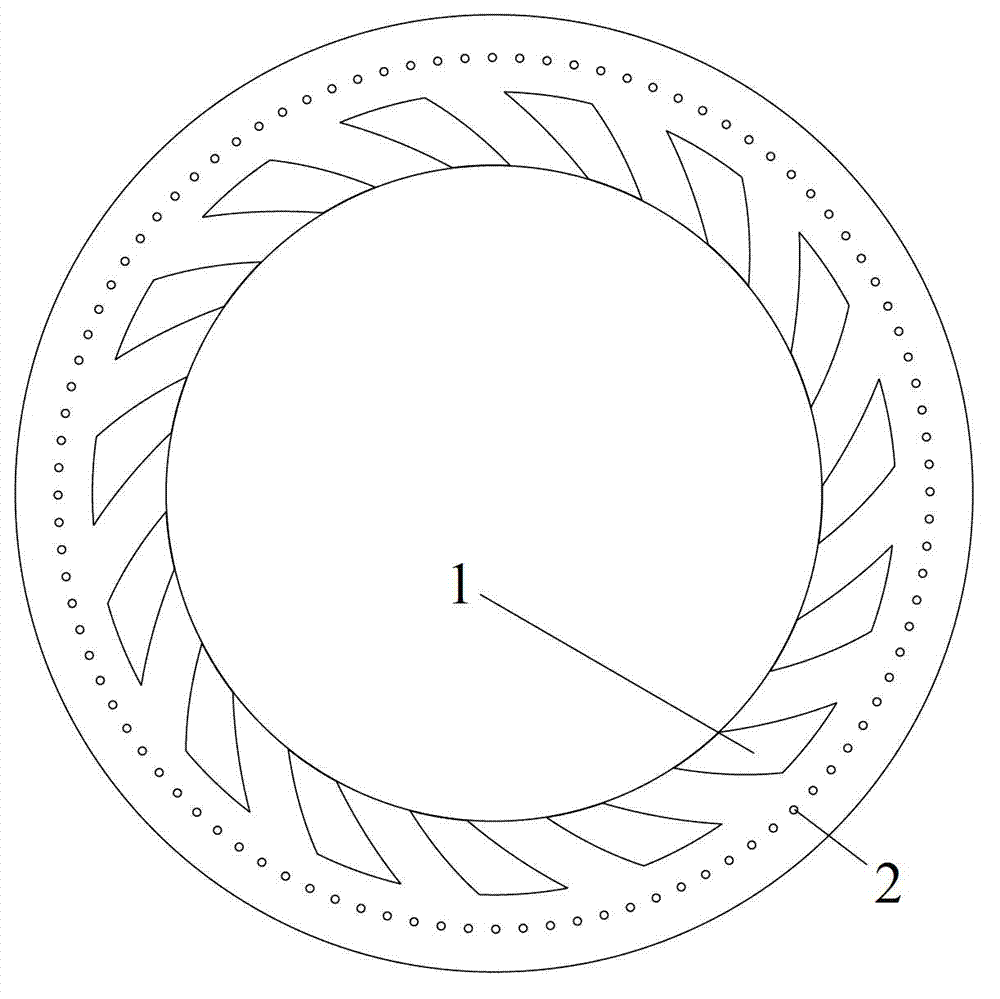

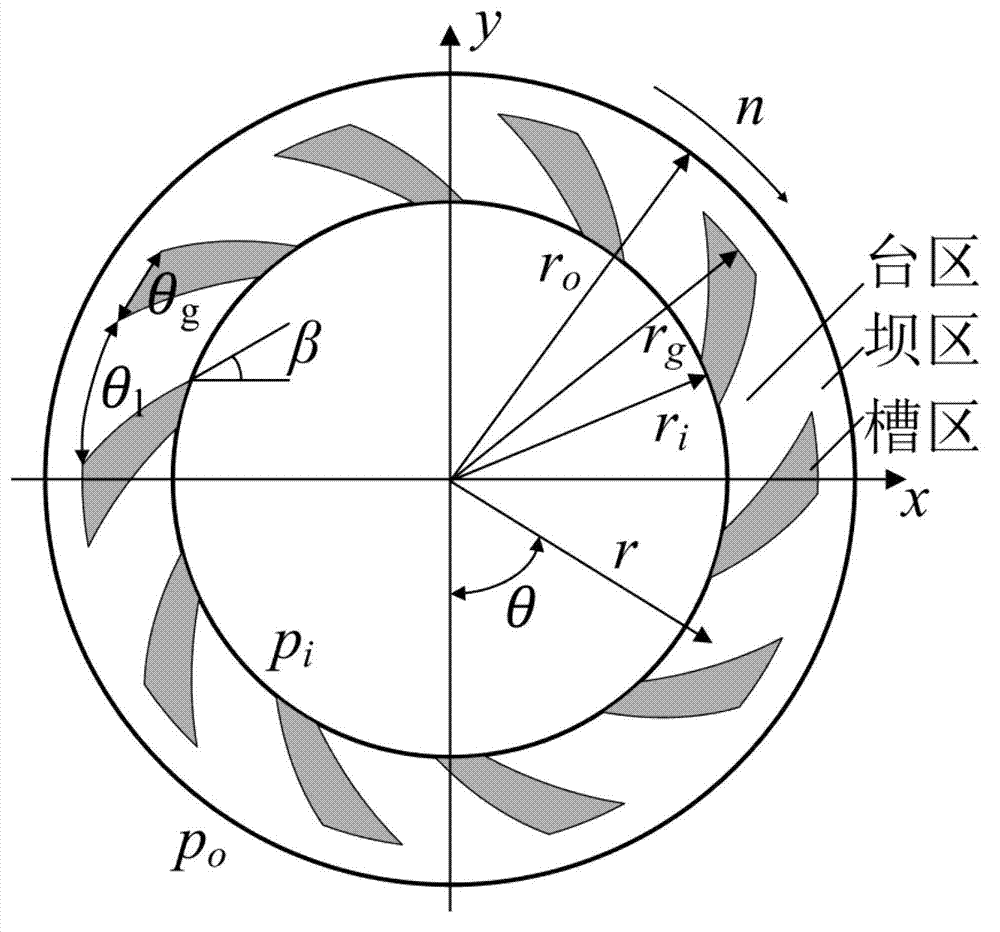

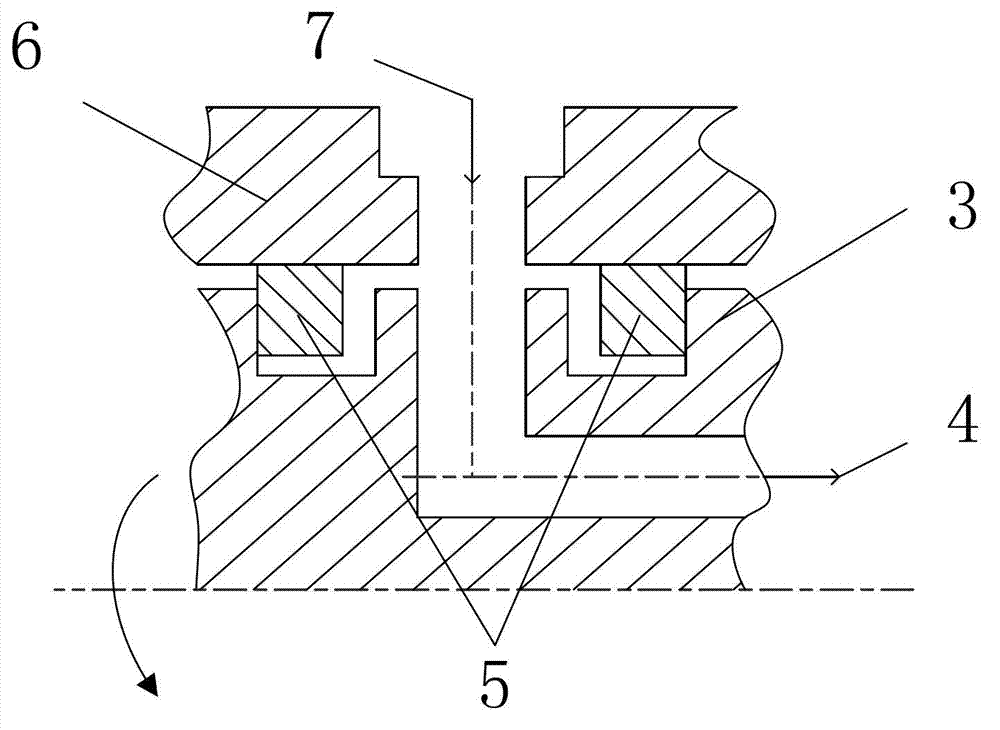

[0018] as attached figure 1 and attached figure 2 As shown, the present invention provides a spiral groove rotary seal ring for vehicles with a porous end face, 15 spiral grooves 1 and 80 microholes 2 are evenly distributed on the end face of the rotary seal ring along the circumferential direction, and each spiral groove 1 It is extended from the inner circle to the outer circle of the sealing ring, the area formed between adjacent spiral grooves 1 is the platform area, the area formed between the top circle of the spiral groove and the outer circle of the sealing ring is the dam area, and the microholes 2 along the circumference Evenly distributed over the dam area of the seal ring.

[0019] Each microhole 2 is a circular hole with a radius of 0.2 mm, and the aspect ratio of the microhole 2 is 0.008.

[0020] The helix angle θ of the spiral groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com