Acrylic ester-attapulgite composite oil-absorbing material and preparation method thereof

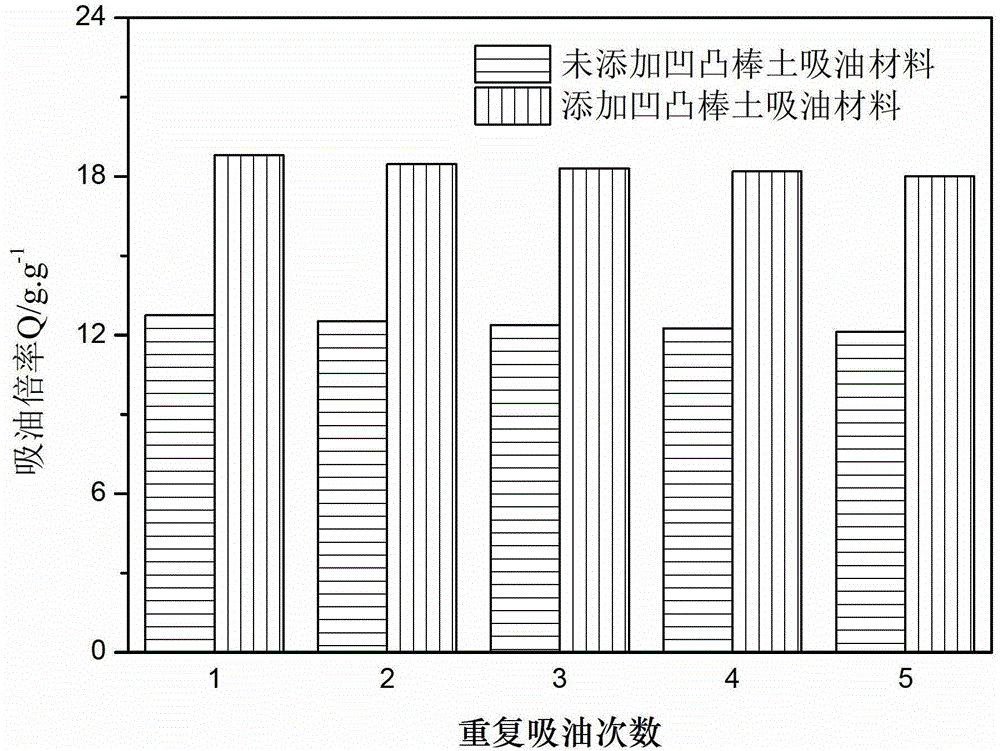

A technology of acrylate and attapulgite, which is applied in the field of acrylate-attapulgite composite oil-absorbing materials and its preparation, can solve the problems of unfavorable recycling and poor mechanical properties, and achieve easy recycling, increased hardness, high The effect of oil absorption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of attapulgite modified by silane coupling agent: Add 100ml of toluene, 1ml of water and 3.0g of attapulgite to the reactor successively (pre-dried at 105°C for 2h), then add 3ml of γ-(methyl Acryloyloxy)propyltrimethoxysilane (KH-570), ultrasonic at 40-45°C for 40 minutes; then react at a constant temperature of 45-50°C under stirring for 4 hours, and the reaction product is filtered and separated with toluene and absolute ethanol in sequence Wash with deionized water to remove excess KH-570, and dry at 105°C to obtain silane coupling agent-modified attapulgite, which is ground and passed through a 200-mesh sieve for later use.

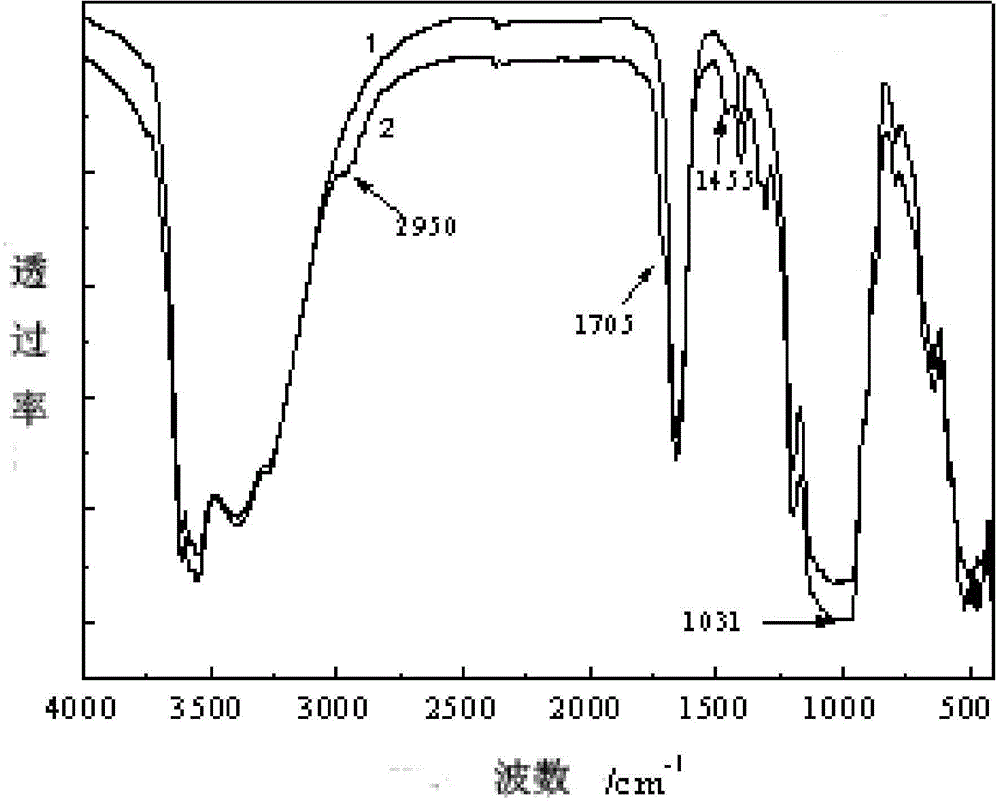

[0026] The infrared spectra of attapulgite (spectrum line 1) and attapulgite (spectrum line 2) obtained after modification with silane coupling agent are as follows: figure 1 shown. Of which 1705cm -1 and 1455cm -1 It is the characteristic peak of KH570 modified attapulgite, respectively representing carboxyl group (-COO-) and c...

Embodiment 2

[0029] Preparation of acrylate oil-absorbing materials: Add 60ml of polyvinyl alcohol aqueous solution (containing 0.6g of polyvinyl alcohol) into a three-necked flask with a stirrer and a condenser, then raise the temperature to 50°C, 2 In the case of protection, add monomer (11.66g butyl methacrylate and 8.34g styrene), initiator (0.2g azobisisobutyronitrile) and crosslinking agent (0.1g divinylbenzene ), stirred evenly, raised the temperature to 70°C, and continued to stir and react for 6h. After the reaction, the product was cooled, washed with hot water at 60°C, and then washed with ethanol, suction filtered, and dried to obtain granular oil-absorbing materials. The oil absorption ratio of this material to toluene is 12.75g / g.

[0030] In this embodiment, the weight ratio of each raw material is: 58.3 parts of butyl methacrylate, 41.7 parts of styrene, 1 part of initiator, 0.5 part of crosslinking agent, and 3 parts of dispersant.

Embodiment 3

[0032] Preparation of acrylate-attapulgite composite oil-absorbing material: Add 60ml of polyvinyl alcohol aqueous solution (containing 0.6g of polyvinyl alcohol) into a three-necked flask equipped with a stirrer and a condenser tube, then raise the temperature to 50°C, 2In the case of protection, add monomer (11.66g butyl methacrylate and 8.34g styrene), initiator (0.2g azobisisobutyronitrile), crosslinking agent (0.1g divinylbenzene ) and silane coupling agent-modified attapulgite (0.6g), stir evenly, raise the temperature to 70°C, continue to stir and react for 6h, after the reaction is completed, cool the product, wash it with hot water at 60°C, and then use Wash with ethanol, filter with suction, and dry to obtain granular composite oil-absorbing material.

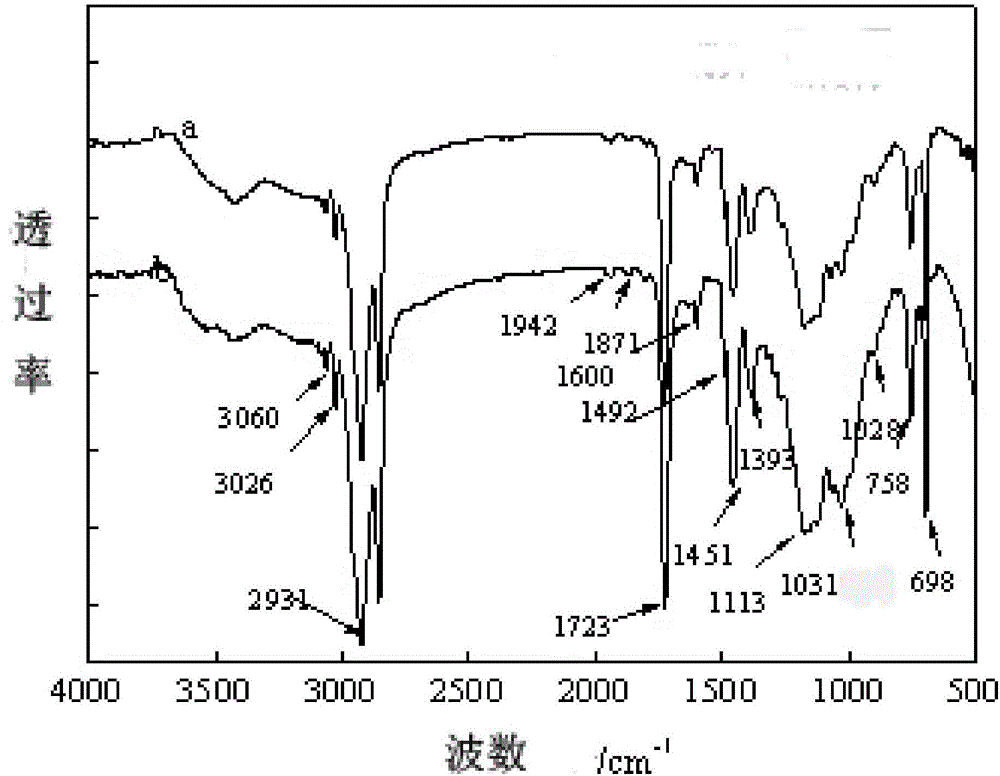

[0033] The infrared spectrum of the oil-absorbing material prepared in embodiment 2 and embodiment 3 is as follows: figure 2 , where curve a represents the oil-absorbing material without modified attapulgite, and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com