Production method for soybean protein

A production method and technology of soybean protein, which are applied to the protein composition of vegetable seeds, protein food ingredients, food science and other directions, can solve the problems of water absorption, low oil absorption, and limit the amount of use, so as to improve the texture of food and increase the amount of use. , the effect of high water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

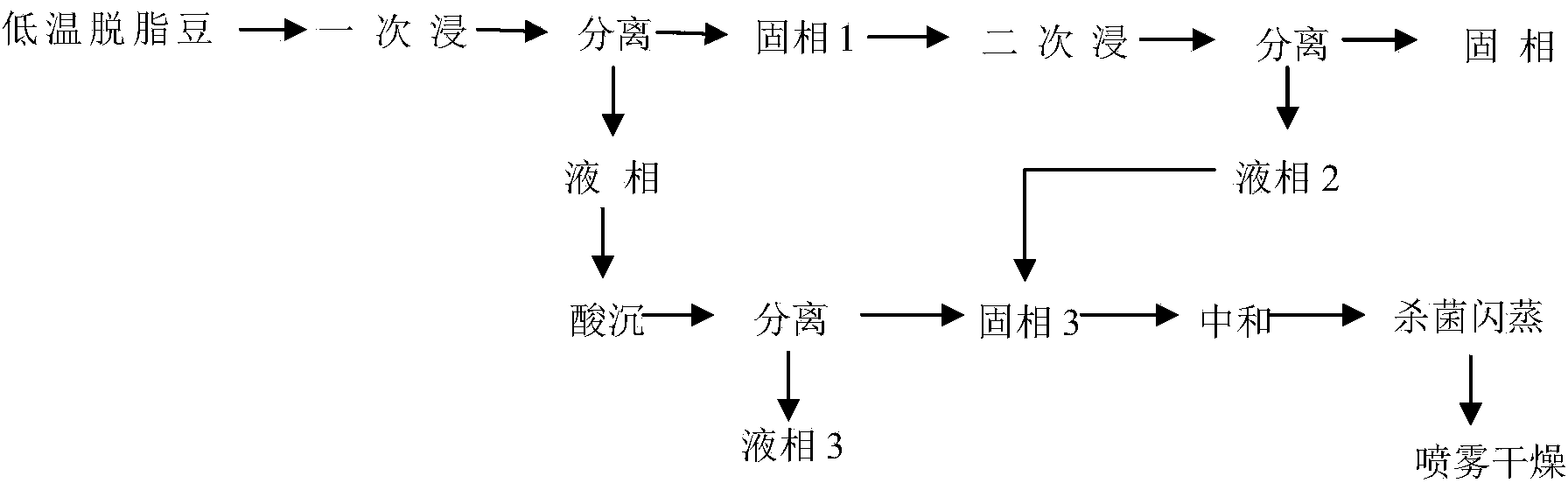

[0034] (1) Primary extraction: mix the raw material low-temperature defatted soybean meal with water at a ratio of 1:10 by weight, adjust the pH value to 7.5, and stir;

[0035] (2) primary separation: after the primary leaching is completed, the extract is centrifuged with a separator, and the separated solid phase 1 enters the secondary leaching process;

[0036] (3) secondary leaching: the solid phase 1 separated by primary leaching is mixed with water of 5 times the weight of the raw material for secondary leaching;

[0037] (4) secondary separation: after the secondary leaching is completed, the extract is centrifuged with a separator to obtain liquid phase 2 and solid phase 2;

[0038] (5) Acid precipitation: adjust the pH value of the liquid phase 1 to 4.5 for sedimentation;

[0039] (6) Centrifugal separation: centrifuge the acid precipitation liquid to obtain the solid phase 3; realize the separation of protein and sugar; the separated liquid phase 3 can be used to e...

Embodiment 2

[0045] (1) Primary extraction: mix the raw material low-temperature defatted soybean meal with water in a ratio of 1::2 by weight, adjust the pH value to 7.2, and stir;

[0046] (2) primary separation: after the primary leaching is completed, the extract is centrifuged with a separator, and the separated solid phase 1 enters the secondary leaching process;

[0047] (3) secondary leaching: the solid phase 1 separated by primary leaching is mixed with water of 5 times the weight of the raw material for secondary leaching;

[0048] (4) secondary separation: after the secondary leaching is completed, the extract is centrifuged with a separator to obtain liquid phase 2 and solid phase 2;

[0049] (5) Acid precipitation: adjust the pH value of the liquid phase 1 to 4.4 for sedimentation;

[0050] (6) Centrifugal separation: centrifuge the acid precipitation liquid to obtain the solid phase 3; realize the separation of protein and sugar; the separated liquid phase 3 can be used to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com