Method for efficiently treating oil-in-water emulsion by using super-hydrophilic nanofiber membrane with gradient structure

A technology of nanofiber membrane and gradient structure, which is applied in fiber treatment, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve the problems of less involvement, achieve simple operation, excellent anti-pollution performance, and use in the preparation of raw materials less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

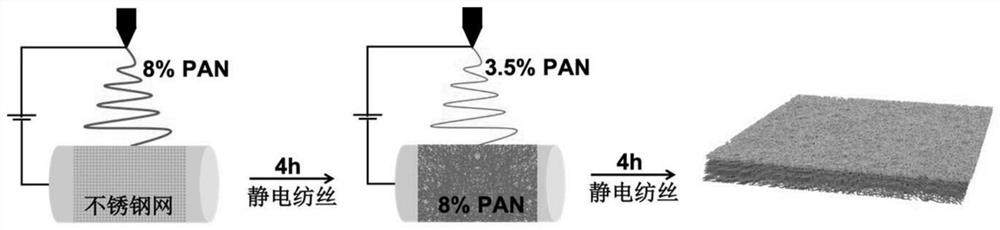

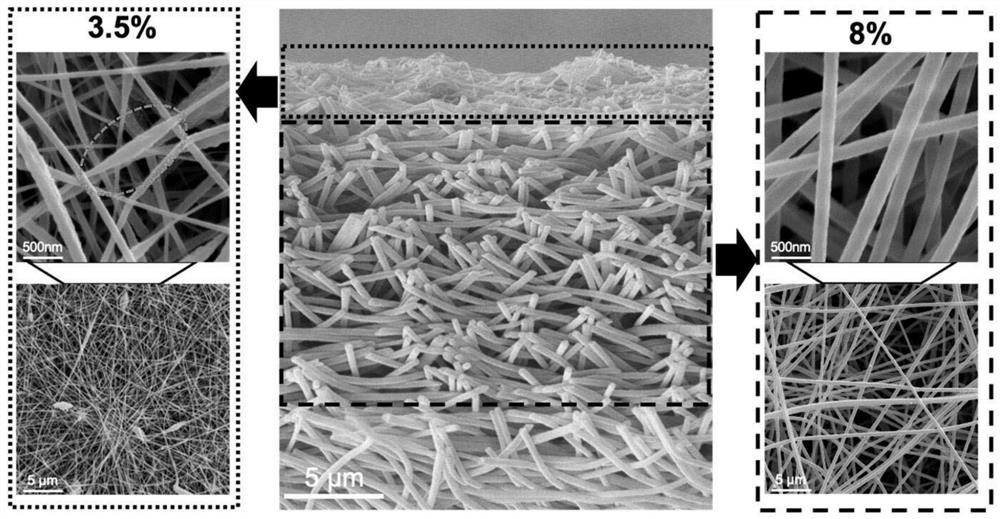

[0049] See attached figure 1 , to prepare superhydrophilic nanofibrous membranes with gradient structures. Select a 500-mesh stainless steel mesh, cut it to a size of 300 mm in length and 210 mm in width, place it in acetone, ethanol, and distilled water for 5 minutes, and then dry it for later use. Weigh 1.6g PAN and dissolve it in 20mL N,N-dimethylformamide, stir magnetically at 500rpm at room temperature for 12h to prepare the first concentration electrospinning working solution with a PAN concentration of 8%, weigh 0.7g PAN and dissolve it in 20 mL of N,N-dimethylformamide was stirred at room temperature at 500 rpm for 12 hours to prepare a second concentration electrospinning working solution with a PAN concentration of 3.5%. Use adhesive tape to fix the stainless steel mesh on the receiving roller of the electrospinning machine, and spin the working solution with a PAN concentration of 8% on the stainless steel mesh. The operating voltage of the electrospinning machine ...

Embodiment 2

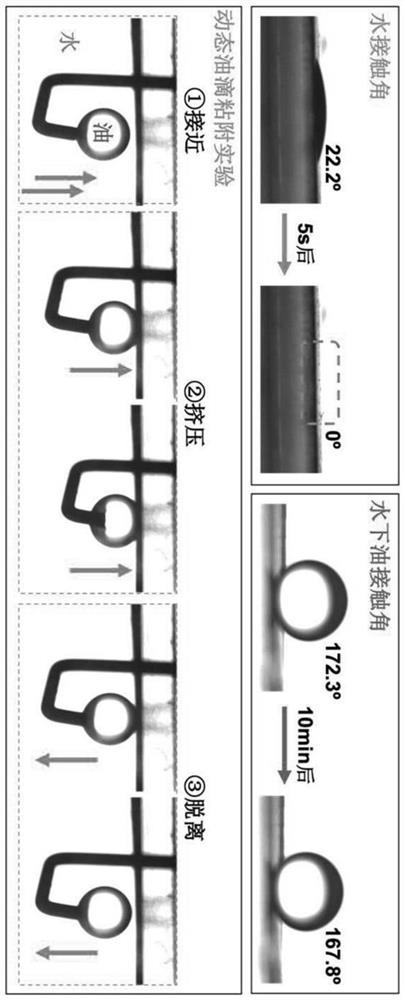

[0053] The ultra-hydrophilic nanofiber membrane with gradient structure prepared in Example 1 was used to treat the surfactant-stabilized nanoscale oil-in-water emulsion NE1 with a driving force of 3.0kPa, and multiple cycles were used continuously for oil-water separation. The efficiency, treatment flux and flux recovery rate were used to investigate the oil-water separation effect, anti-pollution and reusability. The results are attached Figure 4 As shown, using this method to treat nano-scale oil-in-water emulsion NE1, the treatment flux is 1143.33LMH, and the flux recovery rate is as high as 99.98%; in the process of continuous use for 8 times, the oil retention rate is 94.16%-97.20%, Percentage of treatment flux and initial flux (Ji / J 0 ) are higher than 90.9%, and the flux recovery rate is still greater than 86% after being reused for 6 times, which proves that the prepared superhydrophilic nanofibrous membrane with gradient structure of the present invention has highe...

Embodiment 3

[0055] The nano-scale oil-in-water emulsions NE1 and NE2 stabilized by anionic or cationic surfactants were treated with the superhydrophilic nanofibrous membrane with a gradient structure prepared in Example 1. The driving force was 3.0 kPa, and the oil rejection rate, filtrate The light transmittance and treatment flux were used to examine the oil-water separation effect. The results are attached Figure 5As shown, using this method to deal with anion / cation surfactant-stabilized nanoscale oil-in-water emulsions can achieve a very ideal oil-water separation effect, and the oil interception of anionic surfactant (SLS)-stabilized nanoscale emulsion NE1 The rate and light transmittance are 95.68% and 94.3% respectively, and the treatment flux is 1143.33LMH / bar, while the treatment of cationic surfactant (CTAB) stabilized nano-emulsion NE2 is slightly inferior, and the oil retention rate and light transmittance are respectively 92.51% and 92.4%, the processing flux is 935.45LMH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com