Method for extracting peanut dietary fibers through steam explosion modification and enzymatic hydrolysis coupling

A dietary fiber and modification technology, which is applied in the field of combining steam explosion modification and enzymatic hydrolysis to extract peanut dietary fiber, can solve the problems of unfavorable industrial production, lack of effective combination, low product activity, etc. The effect of increasing oil force and swelling force and improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

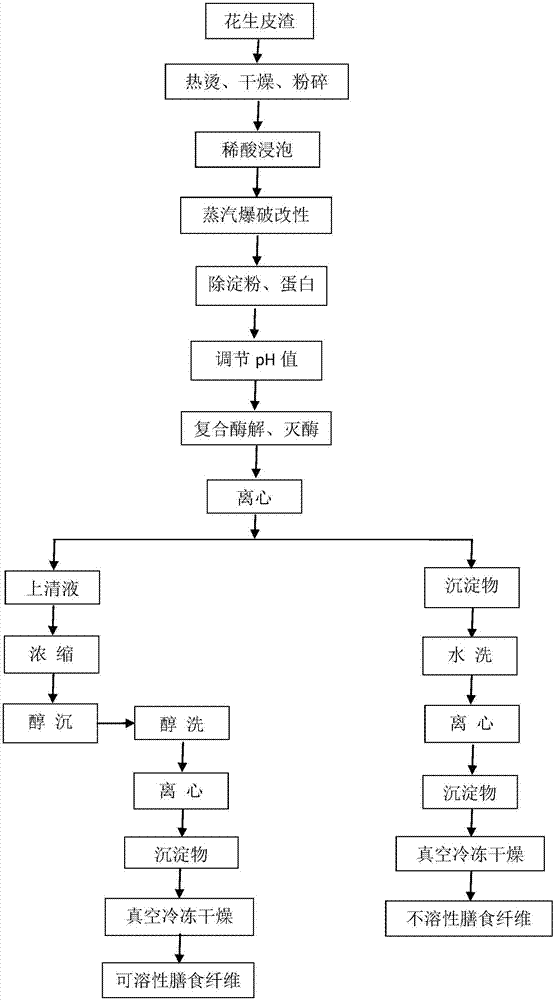

Image

Examples

Embodiment 1

[0036] (1) Wash the peanut skins, blanching them with hot water at 85°C for 2 minutes, drain the blanched peanut skins and put them in a 60°C electric constant temperature blast drying oven to dry for 24 hours to make the water content 8%, crush To 60 mesh, obtain the pretreated peanut shell dregs powder;

[0037] (2) According to the ratio of powder and 0.5% (v / v) sulfuric acid 1g:2mL, add sulfuric acid to soak for 3min, the soaking temperature is 70°C, filter out the acidolysis solution, the humidity of the obtained peanut skin dregs is 50%, and then soak it under a pressure of 2.0 MPa, pressure holding time 10min, steam explosion at a temperature of 120°C to slurry the material and obtain the modified material;

[0038] (3) According to the ratio of modified material and water 1g:3mL, add distilled water to disperse to obtain a dispersion, adjust its pH value to 6.5 with a concentration of 0.5mol / L NaOH solution, and then add high-temperature-resistant α-starch with a mass ...

Embodiment 2

[0046] (1) Wash the peanut skins, blanching them with hot water at 95°C for 3 minutes, drain the blanched peanut skins and put them in a 70°C electric constant temperature blast drying oven to dry for 36 hours to make the water content 6%, crush them To 70 orders, obtain the pretreated peanut shell dregs powder;

[0047] (2) According to the ratio of powder and 1.0% (v / v) sulfuric acid 1g: 3mL, add sulfuric acid to soak for 5min, the soaking temperature is 80°C, filter out the acidolysis solution, the humidity of the obtained peanut skin dregs is 60%, and then soak under a pressure of 3.0 MPa, pressure holding time 15min, and steam explosion at 130°C to slurry the material and obtain the modified material;

[0048] (3) According to the ratio of modified material and water 1g:4mL, add distilled water to disperse to obtain a dispersion, adjust its pH value to 7.0 with a concentration of 0.5mol / L NaOH solution, and then add high-temperature-resistant α-starch with a mass of 0.20%...

Embodiment 3

[0056] (1) Wash the peanut skins, scald them with hot water at 100°C for 1 min, drain the blanched peanut skins and put them in an 80°C electric constant temperature blast drying oven to dry for 24 hours to make the water content 5%, crush them To 80 mesh, obtain the pretreated peanut shell dregs powder;

[0057] (2) According to the ratio of powder and 0.9% (v / v) sulfuric acid 1g: 4mL, add sulfuric acid to soak for 5min, the soaking temperature is 75°C, filter out the acidolysis solution, the humidity of the obtained peanut skin dregs is 60%, and then soak it under a pressure of 2.0 MPa, pressure holding time 20min, steam explosion at a temperature of 140°C to slurry the material and obtain the modified material;

[0058] (3) According to the ratio of modified material and water 1g:5mL, add distilled water to disperse to obtain a dispersion, adjust its pH value to 7.5 with a concentration of 0.5mol / L NaOH solution, and then add high-temperature-resistant α-starch with a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com