Method of improving solubility, water retention and oil retention of soy protein isolate by utilizing ultra-high pressure homogenization combined with enzymatic modification

A soybean protein isolate and soybean protein technology, which is applied in the field of ultra-high pressure homogenization combined with enzymatic modification to improve the solubility and water and oil retention of soybean protein isolate, can solve the problems of decreased emulsifying ability, increased emulsifying activity and stability, etc., to achieve Improved water and oil retention, improved functional properties, and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: present embodiment modifies soybean protein isolate according to the following steps:

[0025] 1. Mix soybean protein and water at a mass ratio of 3-7:100 to prepare a soybean protein isolate solution. After stirring and mixing evenly, it is homogenized by a high-speed homogenizer to better dissolve the soybean protein isolate and avoid ultra-high pressure. During homogenization, clogging occurs due to poor protein solubility, and then ultra-high pressure homogenization treatment is performed. The ultra-high pressure homogenization pressure is controlled at 80-150MPa, and the number of homogenization is 1-3 times;

[0026] 2. Add neutral protease Protex 7L to the soybean protein liquid in step 1 for enzymolysis treatment. The enzyme treatment conditions are: pH=5.5-8.5, water bath temperature 40-60°C, and the amount of neutral protease Protex 7L added is 100-1000U / g soybean protein, the reaction time is 15-120min; heat in a boiling water bath f...

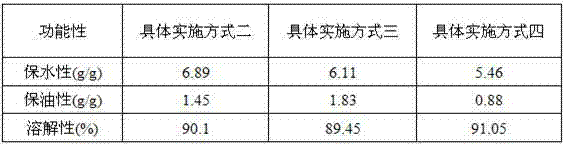

specific Embodiment approach 2

[0028] Specific embodiment two: present embodiment modifies soybean protein isolate according to the following steps:

[0029] 1. Mix soybean protein and water at a mass ratio of 5:100 to prepare a soybean protein isolate solution. After stirring and mixing evenly, first homogenize through a high-speed homogenizer, and then perform ultra-high pressure homogenization treatment, and control the ultra-high pressure homogenization pressure to 100MPa, homogenization times 2 times;

[0030] 2. Add neutral protease Protex 7L to the soybean protein solution in step 1 for enzymatic hydrolysis treatment. The enzyme treatment conditions are: pH=6.5, water bath temperature 45°C, and the amount of neutral protease Protex 7L added is 500U / g soybean protein. The time is 60 minutes; the enzyme is inactivated by heating in a boiling water bath for 15 minutes, and freeze-dried to obtain a modified soybean protein isolate product.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 2 in that the pH value of the enzymolysis treatment solution is 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com