Bilge mechanism of bulk cargo ship

A bulk carrier and bilge technology, applied in the field of shipbuilding, can solve the problems of small utilization space, occupied space, rigidity, etc., and achieve the effect of increasing utilization space, improving utilization space and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

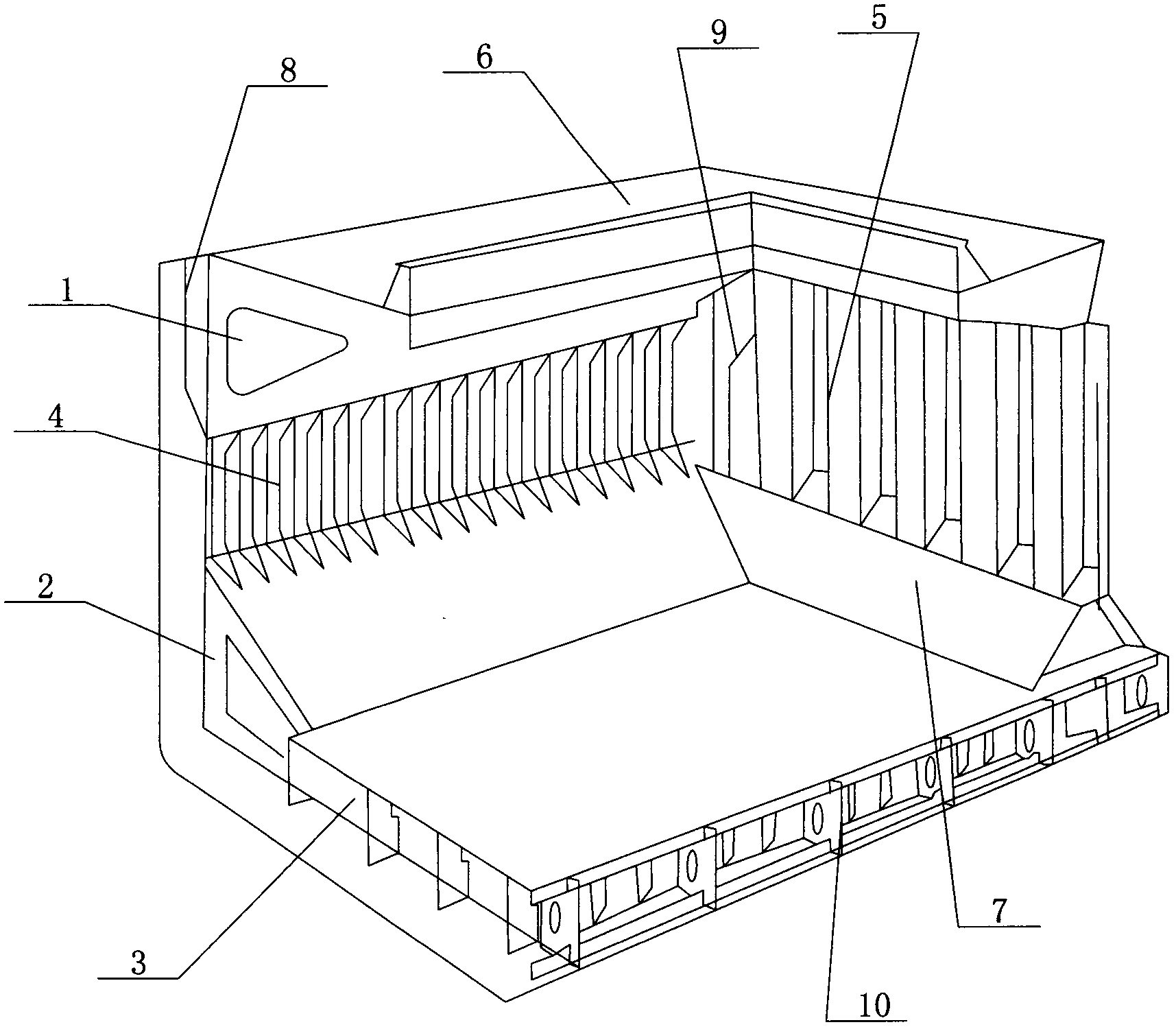

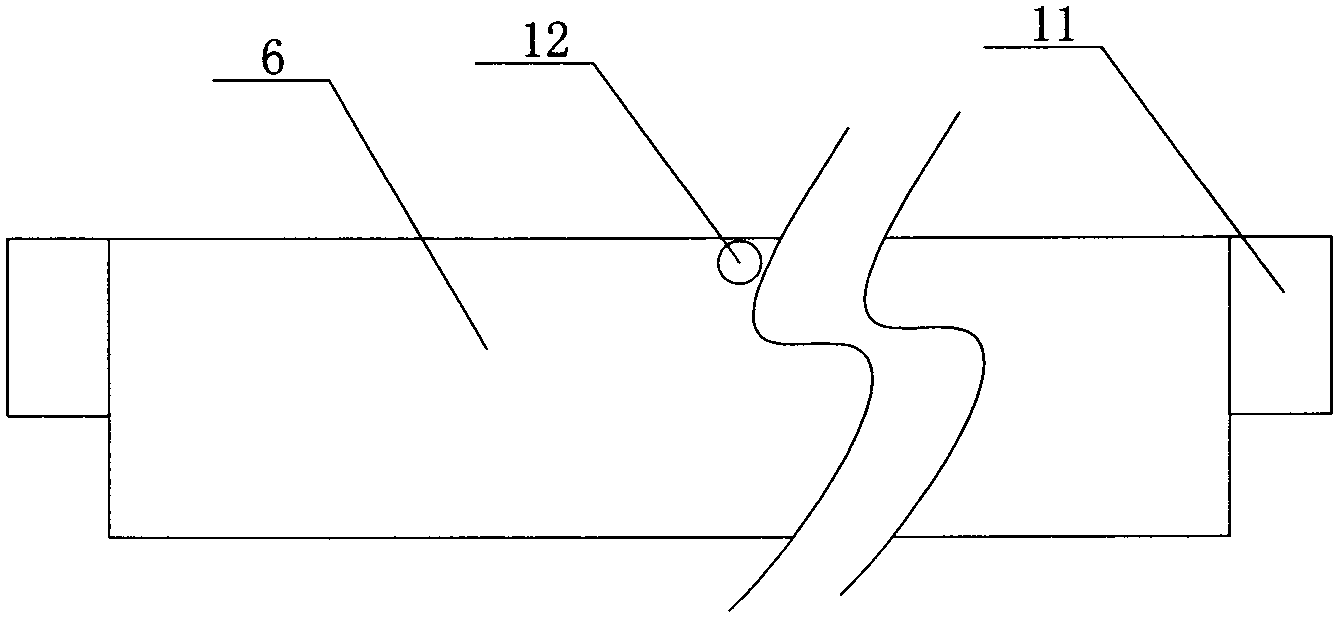

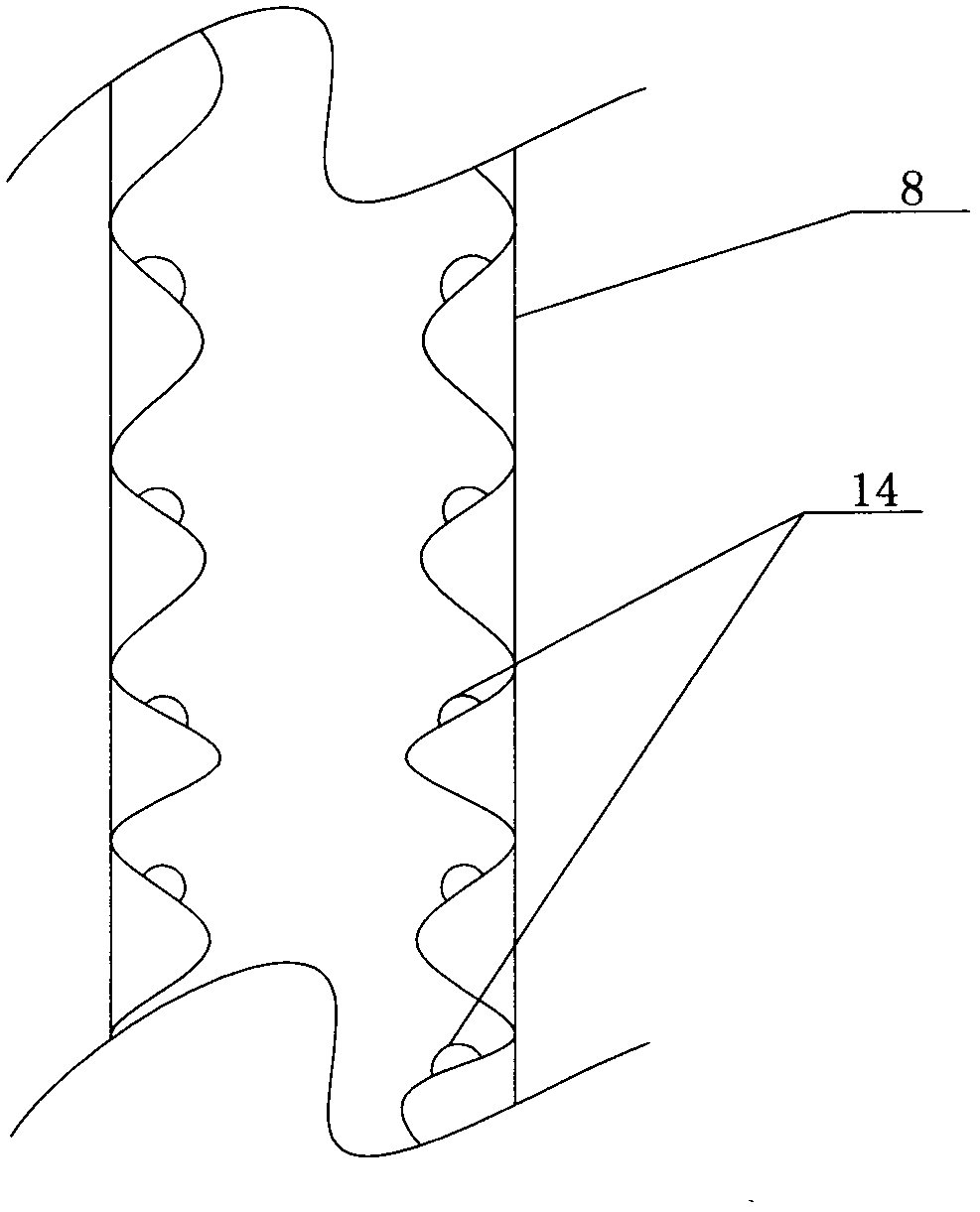

[0019] see Figure 1 to Figure 4 , the specific embodiment adopts the following technical solutions: it includes topside tank 1, hopper tank 2, double bottom tank 3, side ribs 4, transverse bulkhead 5, upper stool 6, lower stool 7, upper slideway 8 , glideway 9, floor plate 10, clamping block 11, height detector 12; topside tank 1 and hopper tank 2 are connected by side ribs 4, hopper tank 2 is connected with double bottom tank 3, double bottom tank 3 Several ribs 10 are evenly arranged in the middle of the bottom tank 3, the upper stool 6 is arranged on the topside tank 1, the upper stool 6 and the lower stool 7 are connected by a transverse bulkhead 5, and the bottom of the upper stool 6 is arranged on the upper In the slideway 8, the top of the lower stool 7 is set in the slideway 9, both sides of the upper stool 6 and the lower stool 7 are provided with clamping blocks 11, and the middle of the upper stool 6 and the lower stool 7 is provided with a height detector 12.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com