Device and method for integrally treating oily sewage at bilge of ship

A treatment method and technology of a treatment device, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as difficult oil-water separation, filter material pollution, blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

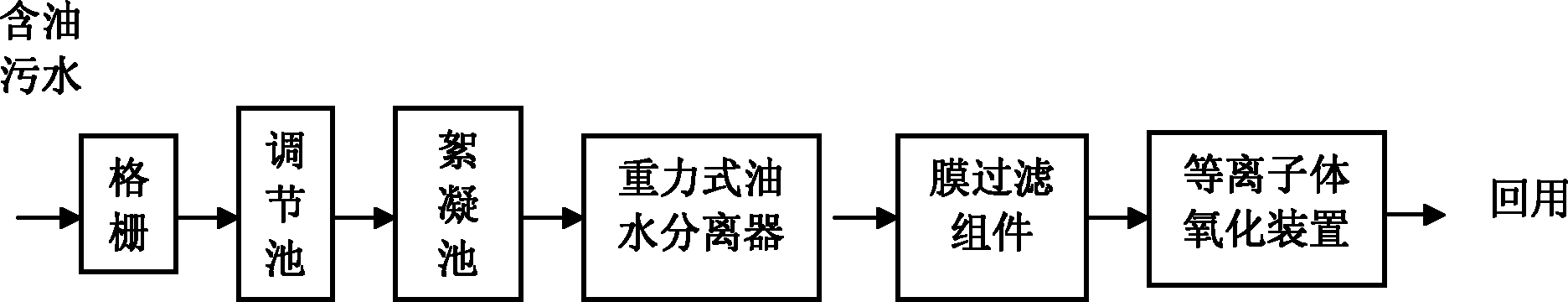

[0025] Specific implementation mode one: the following combination figure 1 A flow chart of the method is described in detail. The oily sewage in the bilge passes through the collection pipeline, passes through the grid 1, and enters the adjustment tank 2. When the water volume reaches a certain level, it enters the flocculation reaction tank 3, and after flocculation, it enters the gravity oil-water separator 4. After passing through the separation action of the gravity oil-water separator, the oily sewage to be treated enters the membrane separation unit 5 . The oily sewage treated by the ultrafiltration membrane enters the mixed gas-liquid two-phase discharge device 6, and the water after final treatment is discharged through the pipeline 7 for use.

specific Embodiment approach 2

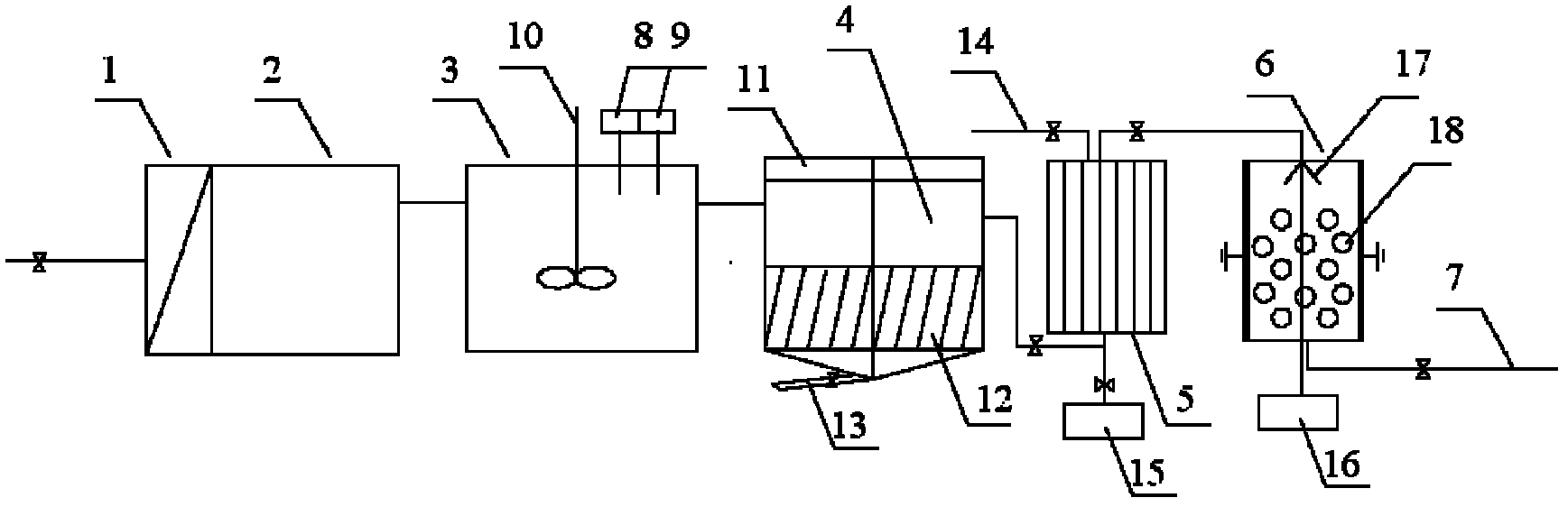

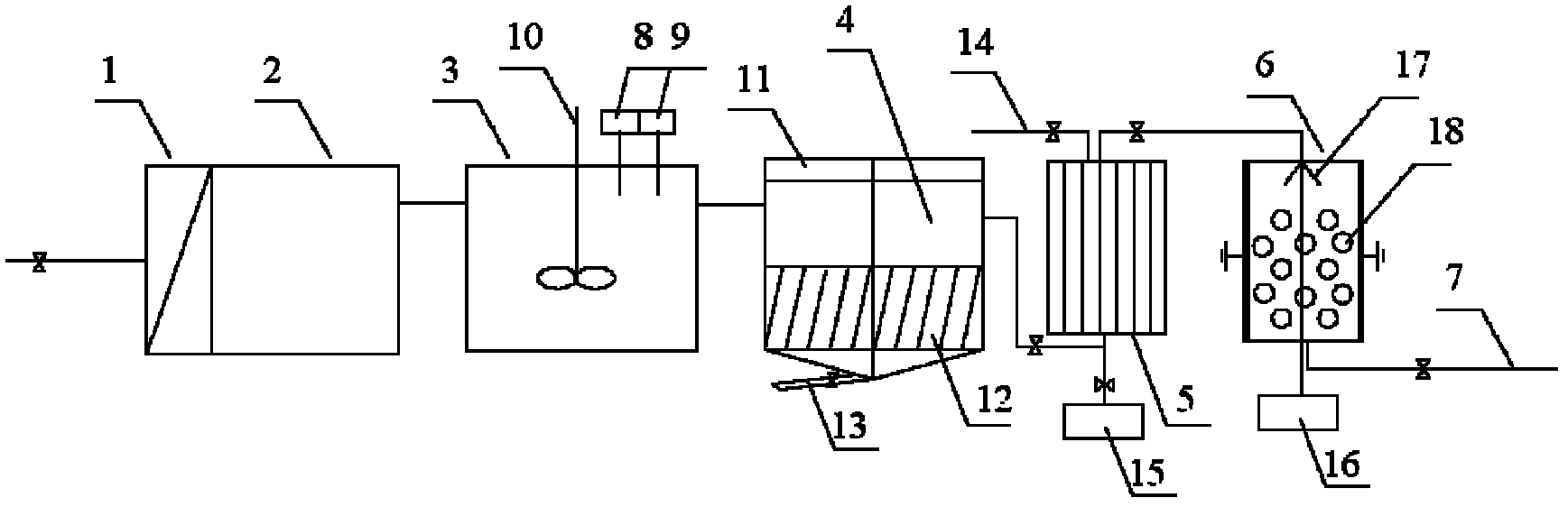

[0026] Specific implementation mode two: the following combination figure 2 A diagram of the setup illustrating the method in detail. The oily sewage in the bilge passes through the collection pipeline, passes through the grille 1, and enters the adjustment tank 2. When the water volume reaches a certain level, it enters the flocculation reaction tank 3, and the coagulant polyaluminum chloride and the coagulant polyacrylamide pass through respectively. Dosing machines 8 and 9 are put into the flocculation reaction tank. The dosage ratio of coagulant and coagulant aid is 100:1-10:1, and the residence time in the flocculation tank is 10-30 minutes. The mechanical flocculation method is adopted, and 10 is a mixer. After flocculation, it enters the gravity oil-water separator 4. The upper part of the gravity type oil-water separator has an oil scraper 11 to collect floating objects; the lower part is a sloping plate structure 12, which allows the dirt with a specific gravity gr...

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the coagulant is polysilica-alumina or polyferric sulfate. Other composition and connection modes are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com