Seawater hole plate of gate at low holds of ship

A technology for inflow holes and seawater, applied to ship accessories, hulls, ship salvage, etc., to achieve the effect of blocking seawater, safe and easy operation, and preventing detachment or loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

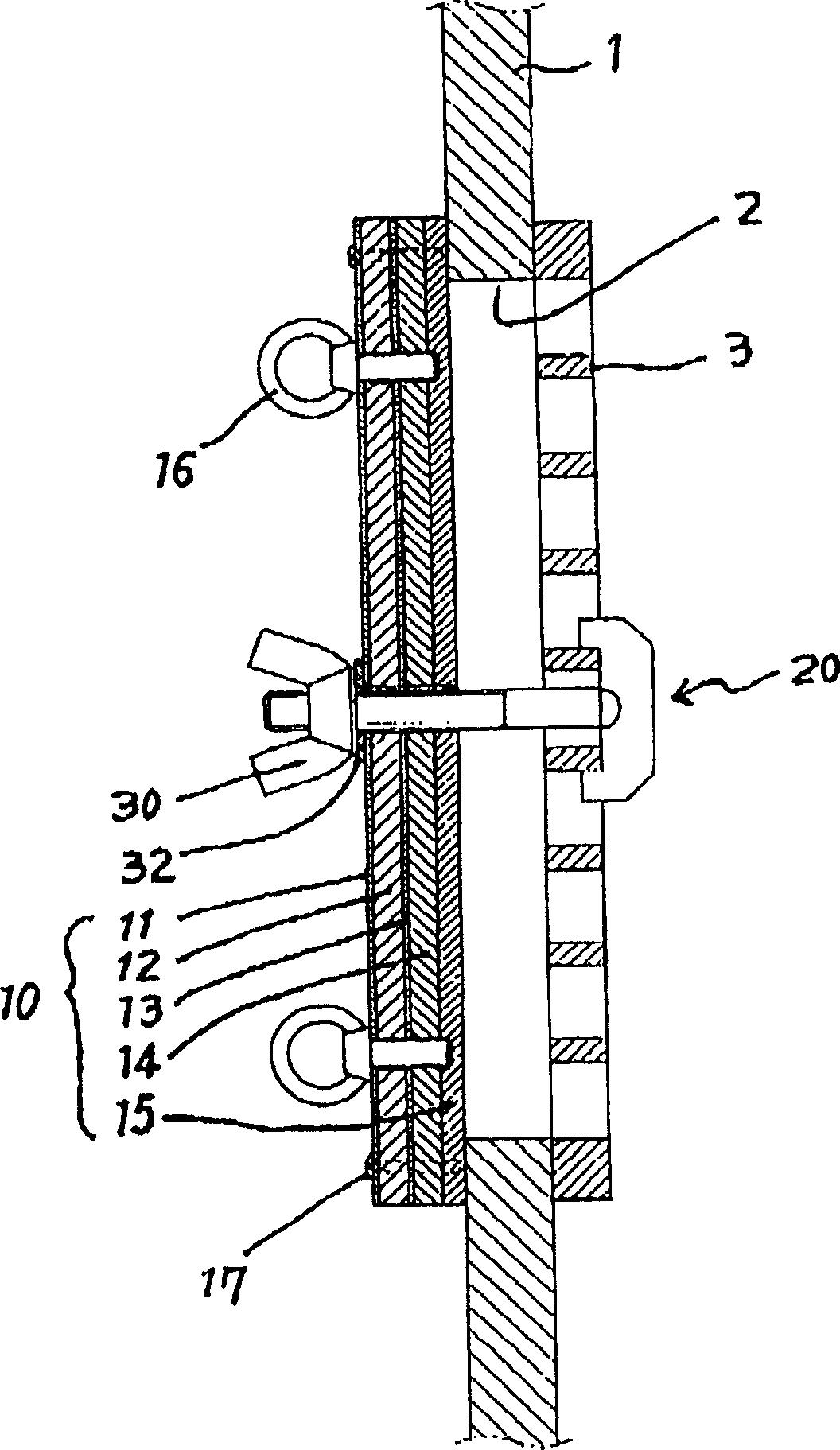

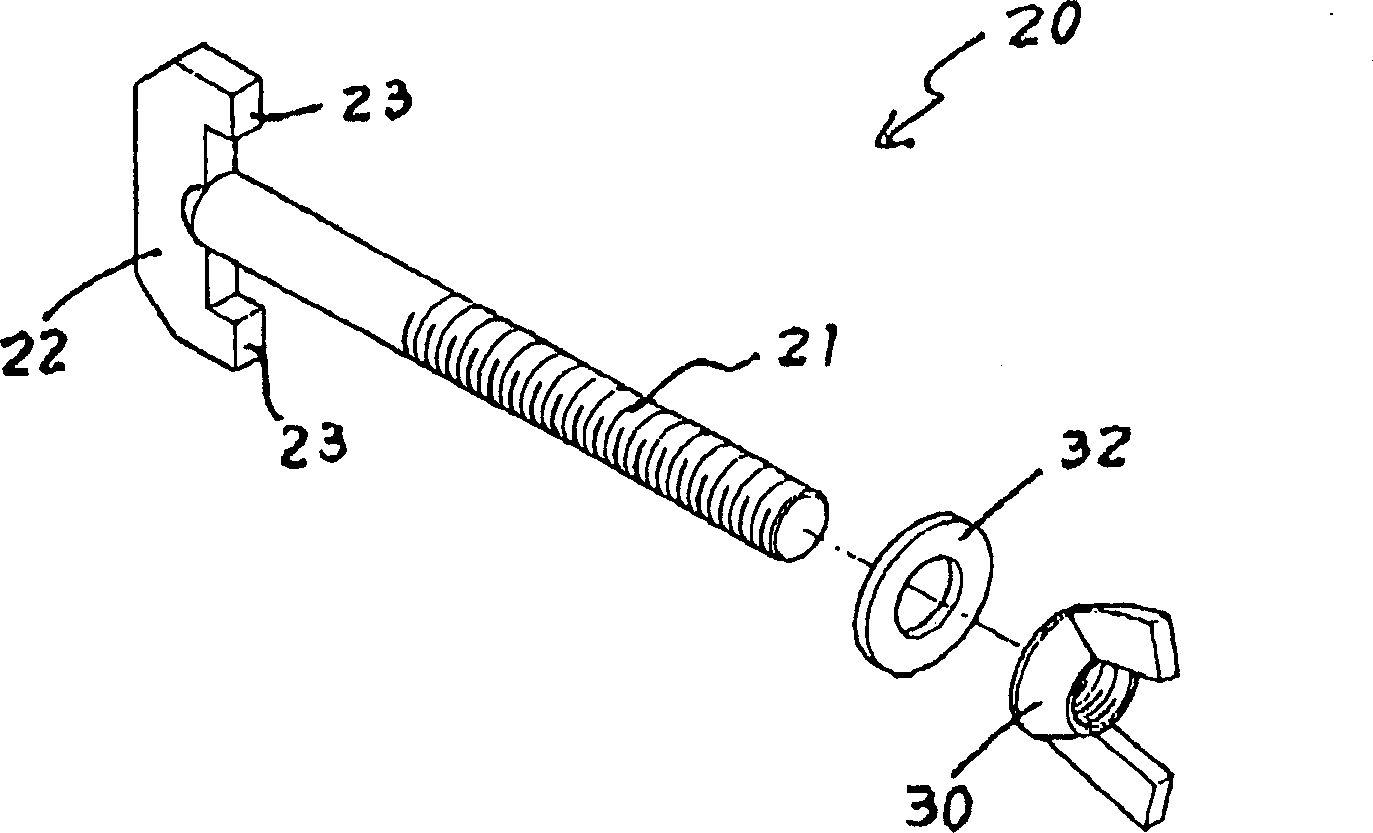

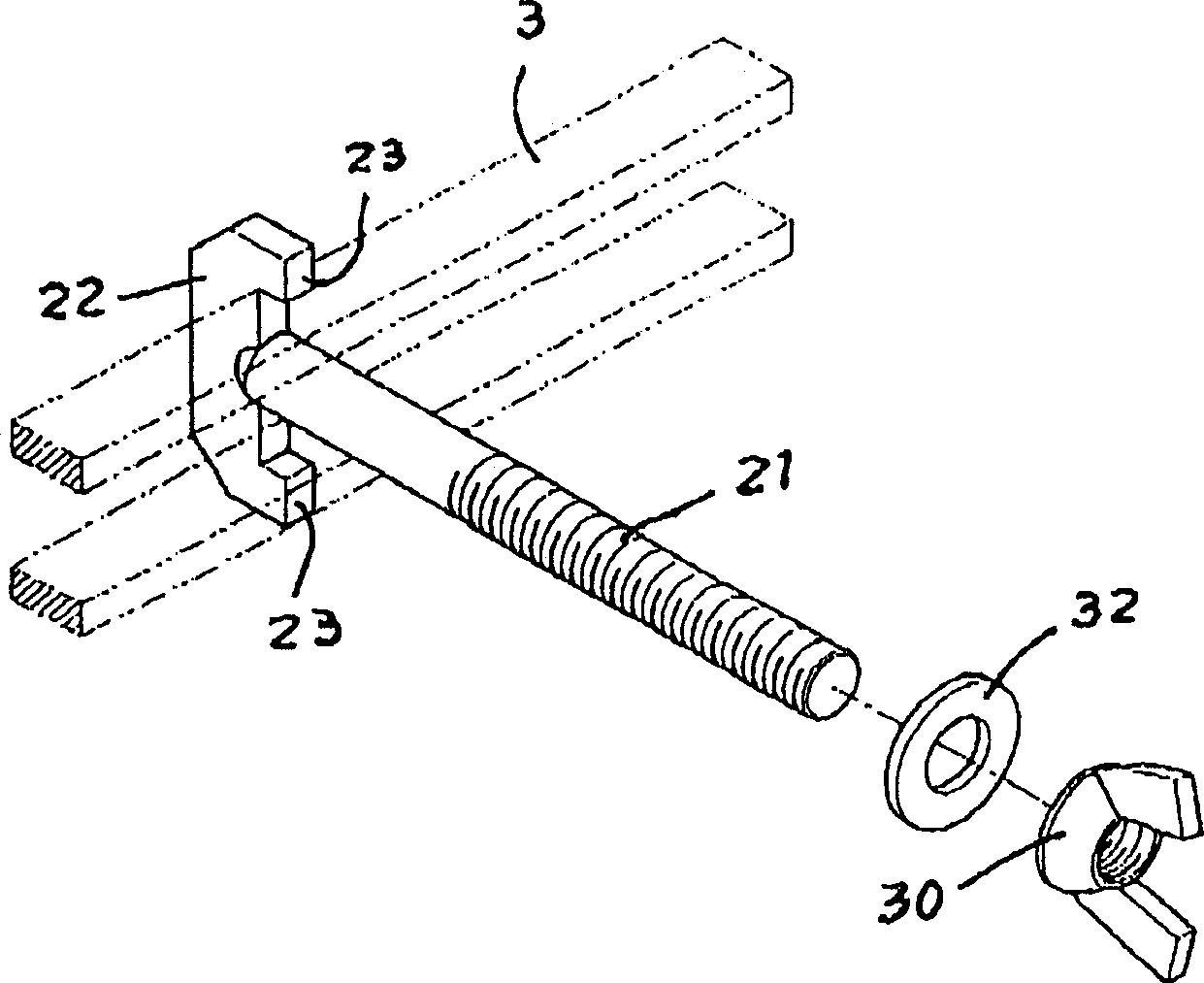

[0025] like Figure 5 As shown, the present invention designs the style of the baffle plate 10 on the basis of the seawater inflow hole 2 formed on the plane part of the hull 1, and takes this as an example for description. If the bilge door 1a including the seawater inflow hole 2 is formed on a part of the hull that constitutes a quadratic curve or a cubic curve, the shape of the baffle plate 10 according to the present invention is also configured as a quadratic curve or a cubic curve. shape. That is, the structure of the baffle plate 10 in the present invention remains unchanged, and still has the shape of a quadratic curve or a cubic curve. At this time, it is possible to use a stamping operation or a casting mold, and realize the curve forming through a general material plastic operation. However, this technology is well-known technology, so it will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com