Method for treatment of oily sewage at bottom of bilge of vessel and method for preparation of magnetic activated carbon for decontamination of oily sewage

A technology of magnetic activated carbon and powdered activated carbon, which is applied in the direction of separation methods, inorganic material magnetism, chemical instruments and methods, etc., can solve problems such as adhesion layer or membrane pore clogging, affect membrane separation efficiency, shorten membrane service life, etc., to prevent membrane Effects of pollution, easy automatic control, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

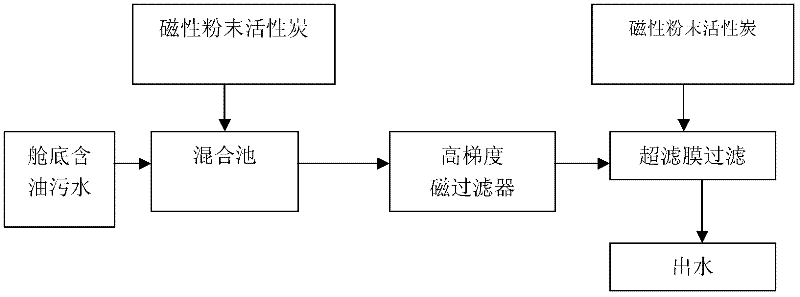

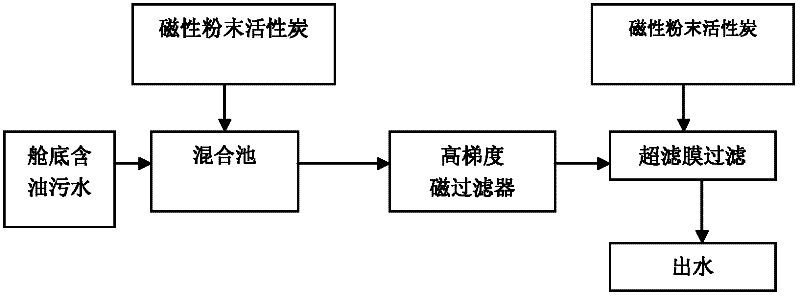

[0027] combine figure 1 , a method for treating ship bilge sewage in the present invention combines the method of adding magnetic powder activated carbon twice with ultrafiltration membrane technology to treat ship bilge oily sewage.

[0028] The first time to add magnetic powder activated carbon is to add a certain amount of magnetic activated carbon continuously in the mixing tank when the oily sewage in the bilge enters the mixing tank, and keep the powder activated carbon in a suspended state by mechanical stirring for adsorption and degreasing, and then through high-gradient magnetic The filter is used to filter and retain the suspended particles in the bilge water and the magnetic powder activated carbon that has absorbed part of the oil. After the high-gradient magnetic filtration step, the ultrafiltration membrane is used to further treat the oily sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com