Method for positioning butt joint of two total sections in large dock shipbuilding

A positioning method and docking surface technology, which is applied to ship components, ship construction, ships, etc., can solve problems such as structural deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

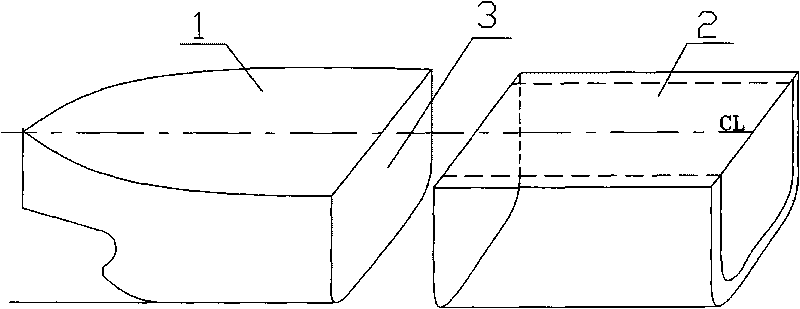

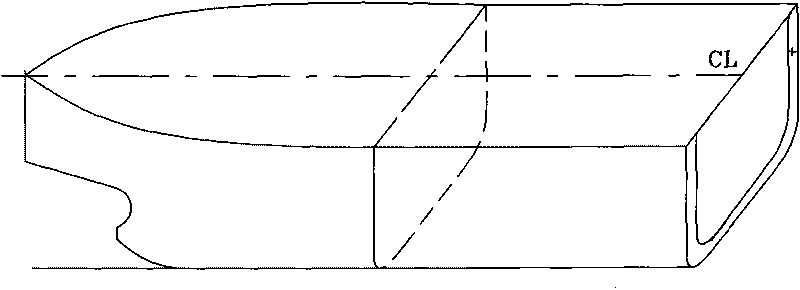

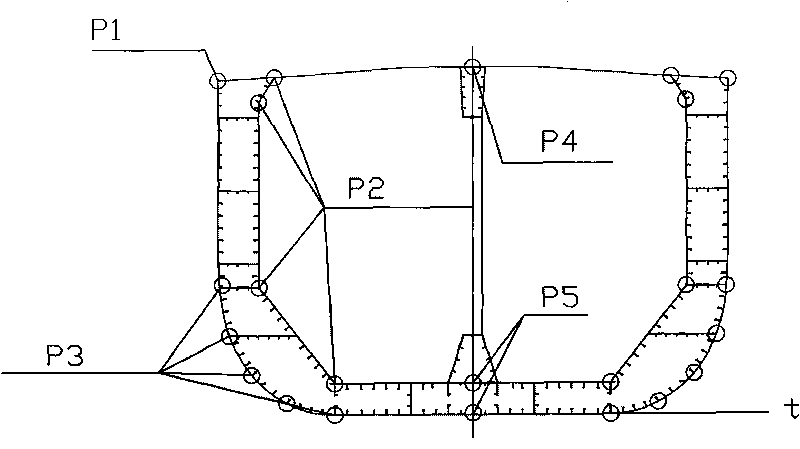

[0010] Such as Figure 1-3 As shown, the present invention is a positioning method for the docking of two general sections of large dock shipbuilding, including the first general section 1 and the second general section 1 to be docked. The inventive method at first measures the following data of the 1st general section 1 docking surface 3, as image 3 As shown, measuring point P1 for molded width or molded depth, measuring point P4 for deck center, measuring point P3 for the outer plating of bilge, measuring point P5 for the center of inner and outer bottom plates, and measuring point P2 for the height of each knuckle of the inner shell plate from the center and baseline . Secondly, the present invention feeds the above-mentioned data back to the second general segment to provide positioning reference data for subsequent positioning of segmental positioning at the closing seam in the second general segment.

[0011] If the present invention wants to ensure the structural ali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com