Straight wall constant wetted length slideway type round bilge speed boat shape

A wet and long slide type, round bilge technology, applied in the direction of ships, hydrodynamic characteristics/hydrostatic characteristics, hull, etc., can solve the limitation of the traditional double-hull circular bilge speedboat's range of use conditions and the reduction of the stability of the speedboat's longitudinal motion. , Wetting length reduction and other problems, to achieve the effect of expanding the range of use conditions, improving the stability of longitudinal motion, and increasing the speed of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention and design method will be further described below in conjunction with accompanying drawings and specific embodiments.

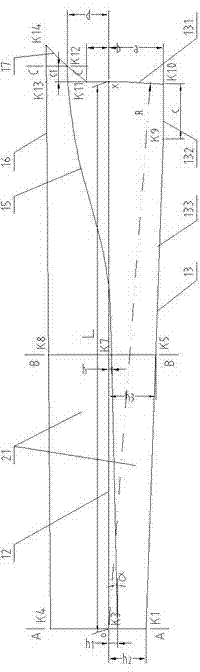

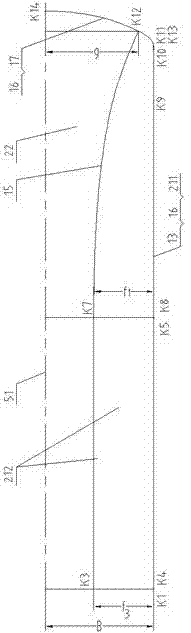

[0022] figure 1 Among them, taking point o as the origin, draw a horizontal line segment ox whose length is equal to the design waterline length L of the hull toward the bow direction, and the line segment ox is the design waterline 12 of the hull.

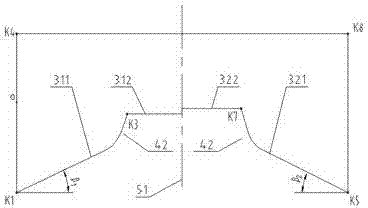

[0023] figure 1 , take point o as the center of the circle, the length L of the design waterline 12 of the hull is the radius R, and an arc K10K11 is drawn to obtain the bow column line 131. The lower endpoint of the arc K10 is below the design waterline 12 of the hull, and the The distance of the design waterline 12 a=L / (9~11), the upper end point K11 of the arc is above the hull design waterline 12, and the distance from the hull design waterline b=(0.2~0.5)a; K10 draws a horizontal straight line toward the stern of the boat, and points K9 are taken on the straight line, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com