Patents

Literature

65 results about "Bilge keel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bilge keel is a nautical device used to reduce a ship's tendency to roll. Bilge keels are employed in pairs (one for each side of the ship). A ship may have more than one bilge keel per side, but this is rare. Bilge keels increase hydrodynamic resistance to rolling, making the ship roll less. Bilge keels are passive stability systems.

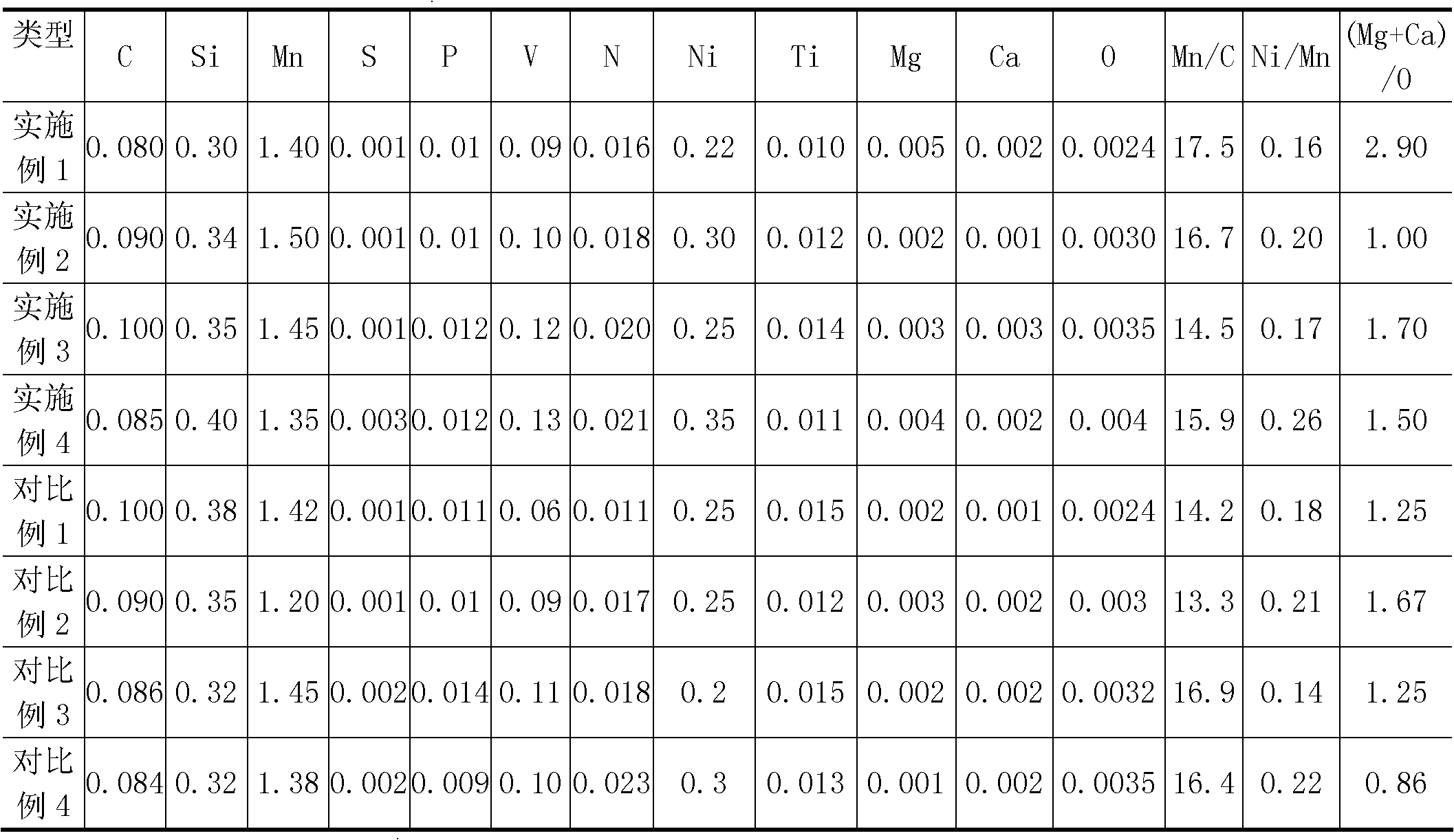

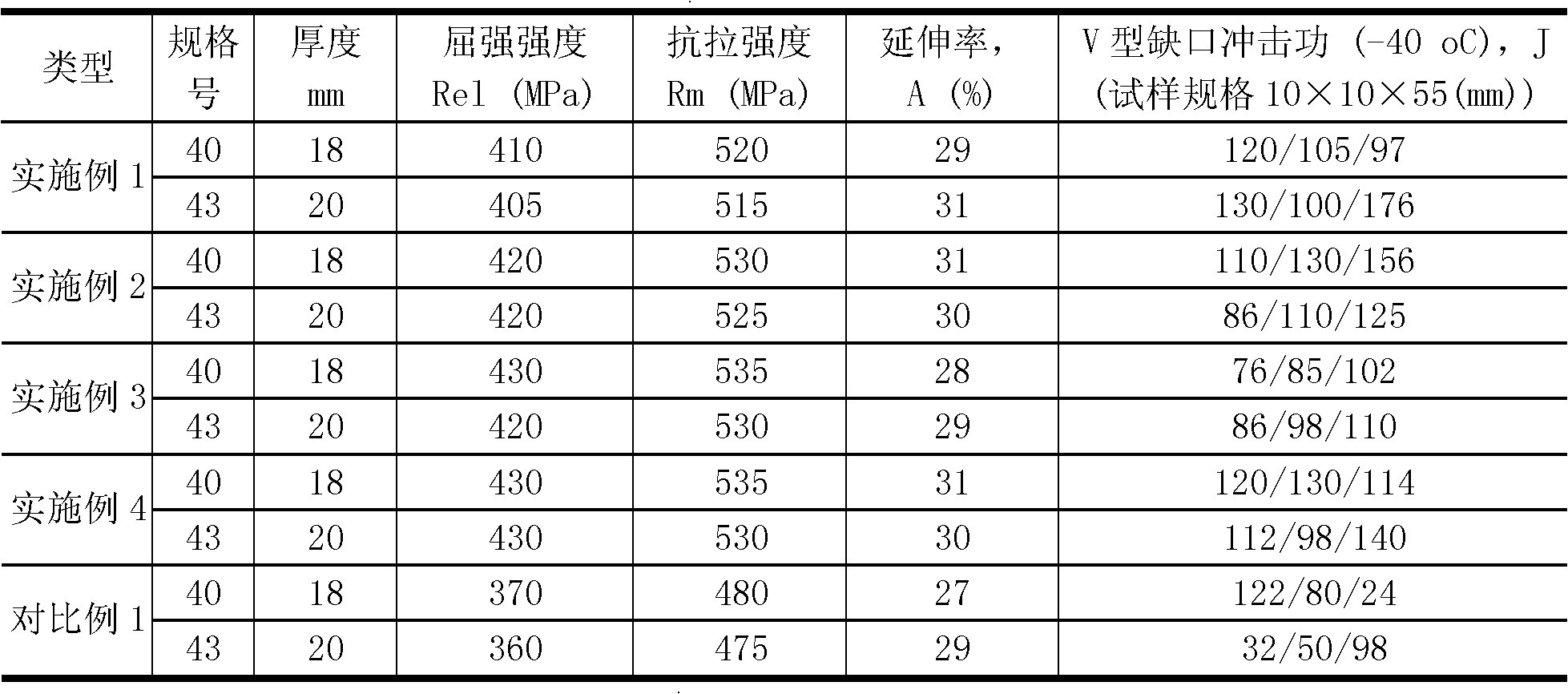

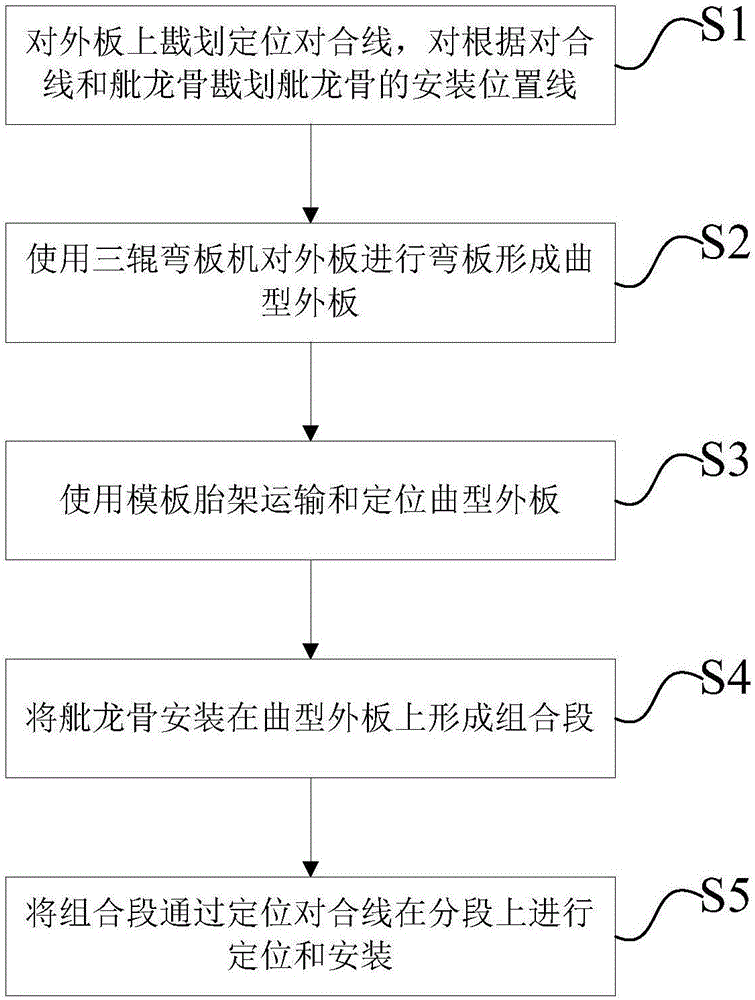

Large-specification and high-strength D40 hot-rolled flat-bulb steel for ships and production process for hot-rolled flat-bulb steel

The invention relates to large-specification and high-strength D40 hot-rolled flat-bulb steel for ships and a production process for the hot-rolled flat-bulb steel, and belongs to the technical field of marine structural steel. The large specification of the large-specification and high-strength hot-rolled flat-bulb steel is No. 40 and over No.40. The steel comprises the following chemical ingredients in percentage by weight: 0.08 to 0.15 percent of C, 0.10 to 0.50 percent of Si, 1.15 to 1.75 percent of Mn, less than or equal to 0.020 percent of S, less than or equal to 0.020 percent of P, 0.08 to 0.15 percent of V, 0.10 to 0.50 percent of Ni, 0.01 to 0.03 percent of Ti, 0.001 to 0.01 percent of Mg, 0.001 to 0.01 percent of Ca, 0.001 to 0.01 percent of O, 0.016 to 0.025 percent of N and the balance of Fe and inevitable impurities, wherein Mn / C is more than or equal to 14.0, Ni / Mn is more than or equal to 0.15, and (Mg+Ca) / O is more than or equal to 1.0. The production process comprises the following steps of: feeding a vanadium nitrogen alloy wire with the diameter of 13 millimeters and a Mg-Ca alloy wire with the diameter of 10 millimeters into molten steel after vacuum is finished, and blowing argon and stirring at the bottom; and in the hot rolling process, heating a low-temperature blank, performing final rolling for large deformation and cooling after rolling. The large-specification and high-strength D40 hot-rolled flat-bulb steel has the advantages that: the requirements of yield strength and impact toughness at the low temperature of -40 DEG C can be met, the flat-bulb steel is used for stiffeners at bilge keels of large-scale ships, and the rigidity of the ships and the safety coefficients of the ships used at the low temperature are improved obviously under the condition that the weight of the ships is not improved.

Owner:CENT IRON & STEEL RES INST

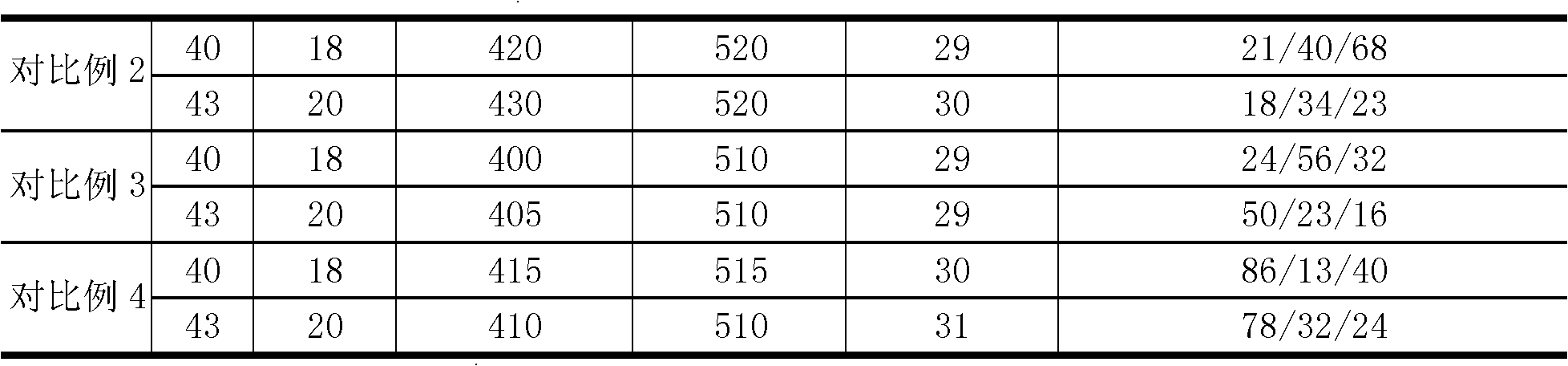

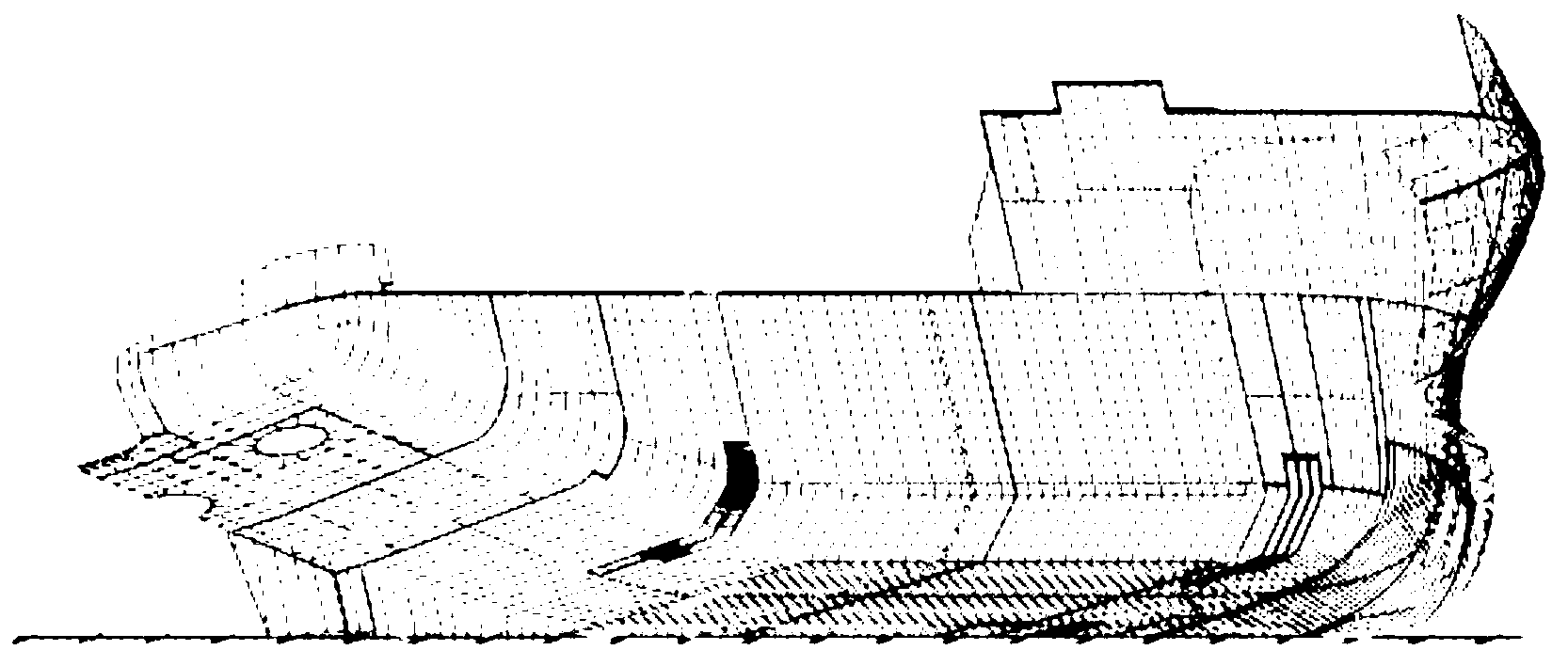

Ship bilge keel positioning and mounting method

ActiveCN106516001AOptimize the segmented construction processReduce installation difficultyVessel designingBilgeKeel

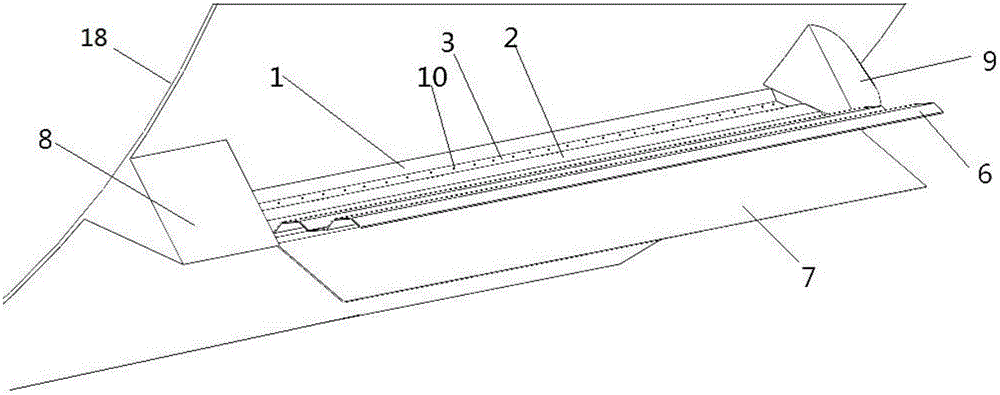

The invention provides a ship bilge keel positioning and mounting method. A bilge keel is mounted on an outer curved plate which is positioned in a bilge section. The method includes steps: S1, marking a positioning joining line on the outer plate, and marking a bilge keel mounting position line according to the positioning joining line and the bilge keel; S2, adopting a three-roll plate bending machine for linear curvature processing of the outer plate to form the outer curved plate; S3, using a moulding bed for transporting and positioning the outer curved plate; S4, mounting the bilge keel on the outer curved plate to form a combined section; S5, positioning and mounting the combined section on the bilge section according to the positioning joining line. At a bilge keel mounting stage, after completion of a large section group, curvature processing of the outer plate of the bilge section is performed before mounting of the bilge keel. A normal-posture faceup installation way of the bilge keel is optimized into a horizontal faceup installation way to lower installation difficulty. Bilge keel installation precision is optimized from rough installation to accuracy control, subsequent reworking is avoided due to angle control of the bilge keel, and the moulding bed guarantees linear precision of the outer curved plate in a placement and transport process to avoid subsequent reworking.

Owner:JIANGNAN SHIPYARD GRP CO LTD

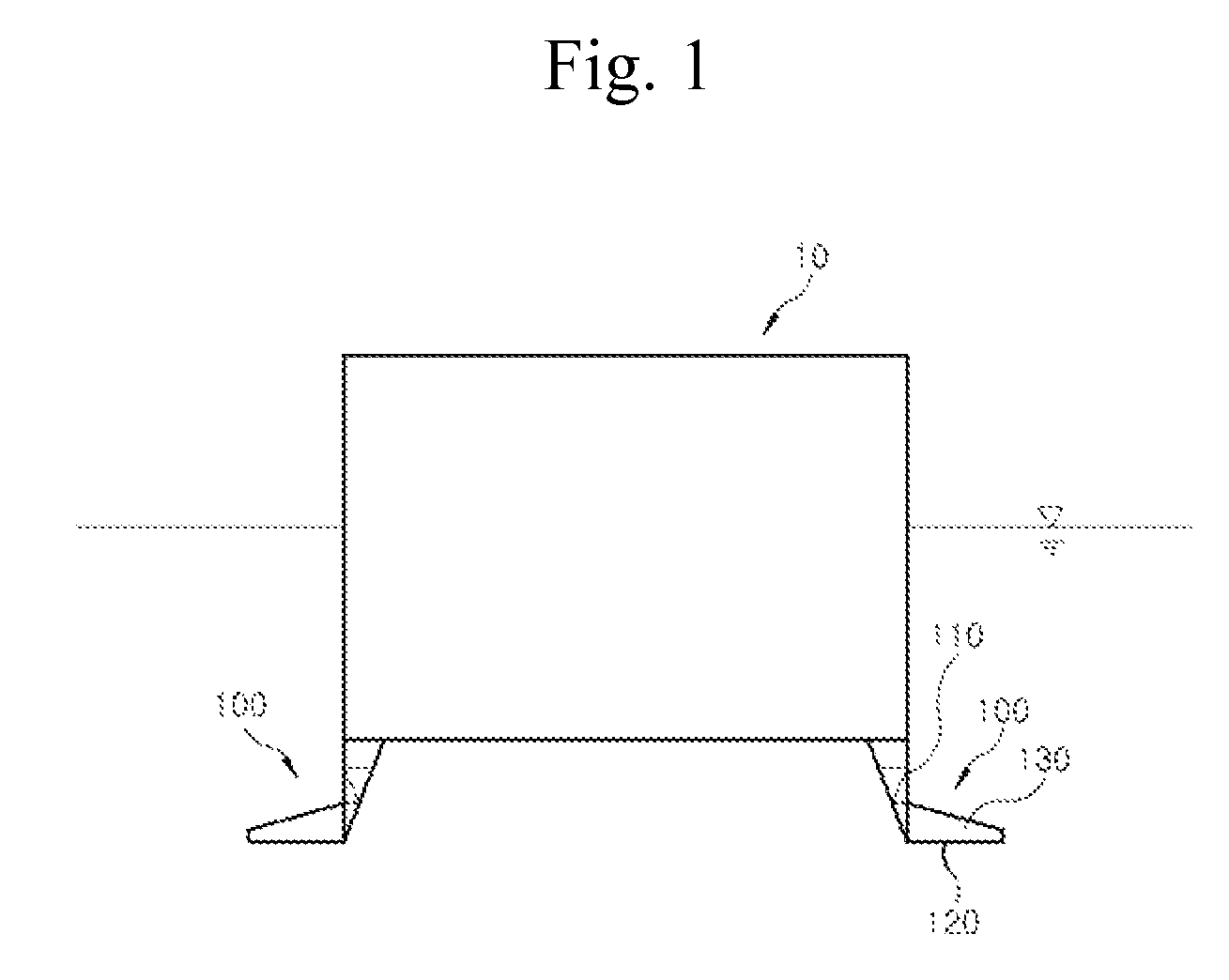

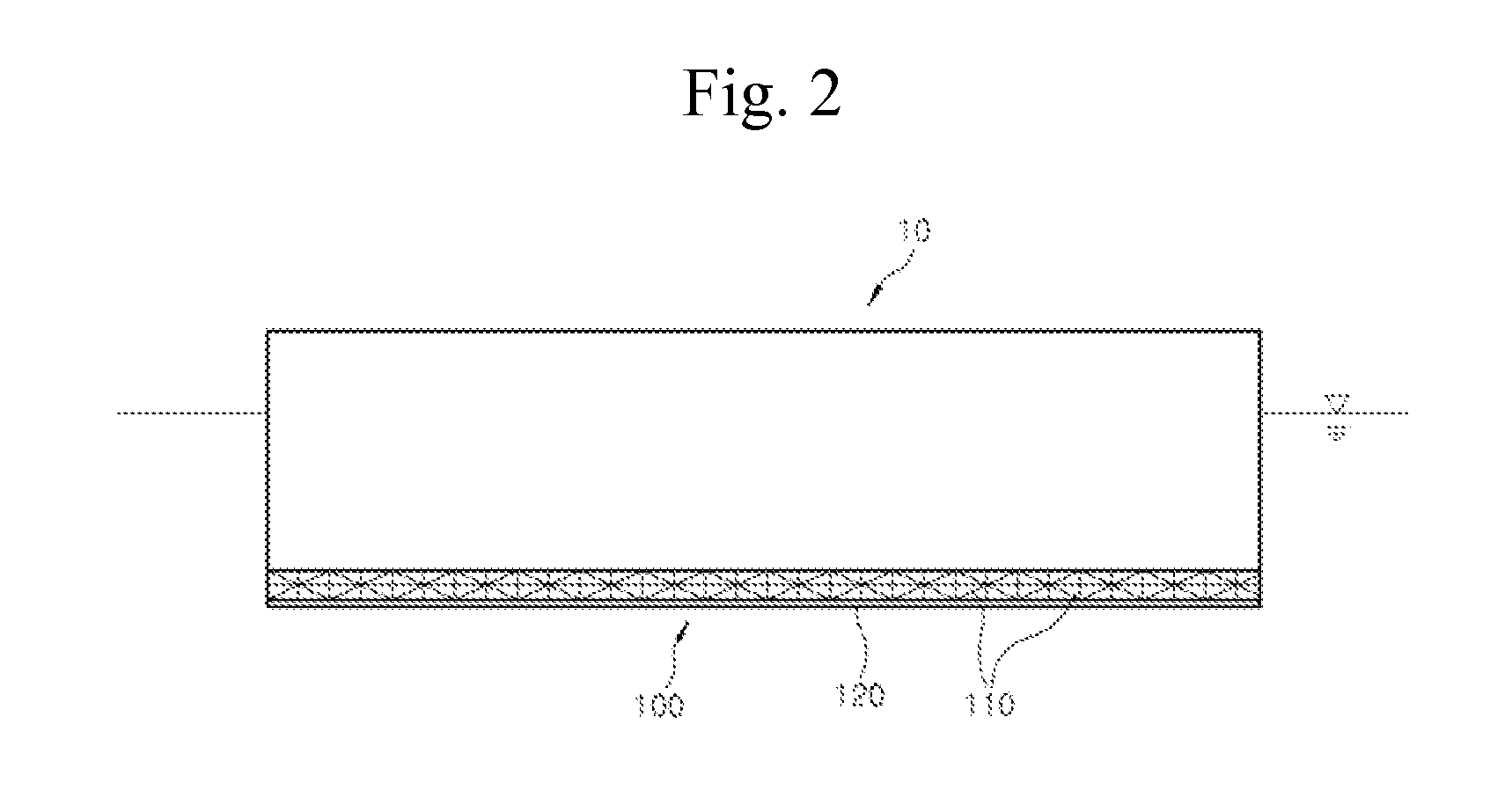

Roll suppression device for offshore structure

InactiveUS20110061578A1Improve efficiencyImprove stabilityVessel movement reduction by foilsVessel safetyMarine engineeringKeel

The present disclosure relates to a roll-suppression device for an offshore structure. The device includes a damping plate separated downward from a hull to be placed below a bottom of the offshore structure by a connection unit, so that the width of the damping plate may be effectively enlarged without occurrence of collision during shuttle docking or ship-to-ship operation. Accordingly, the device may maximize roll-suppression, as compared with a bilge-keel or a step, and a detachable design of the device facilitates ship construction or shore operation inside a drydock.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

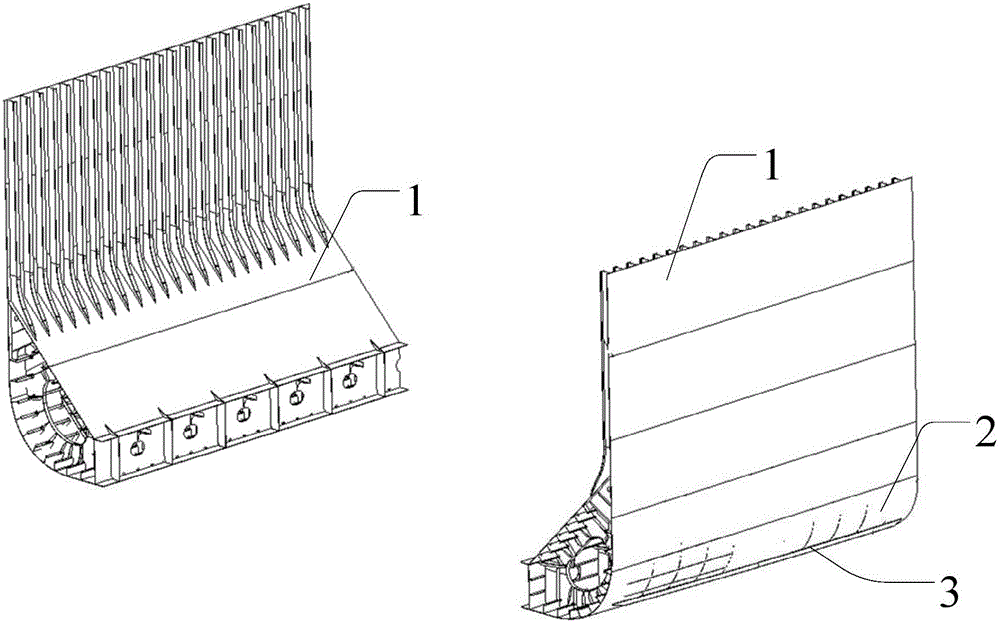

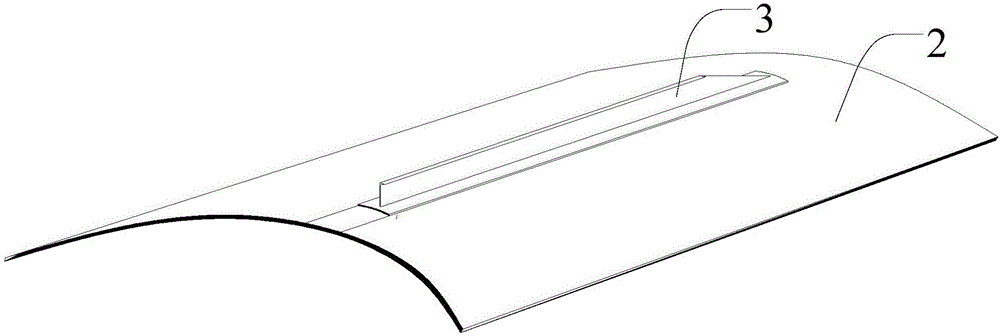

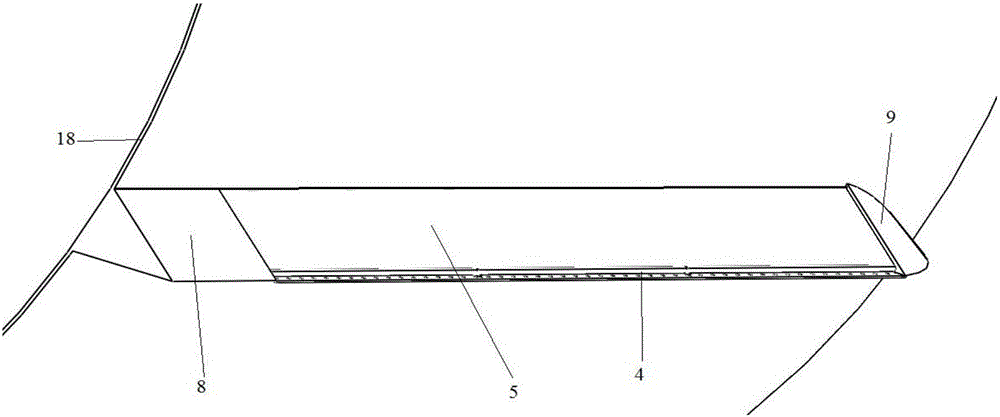

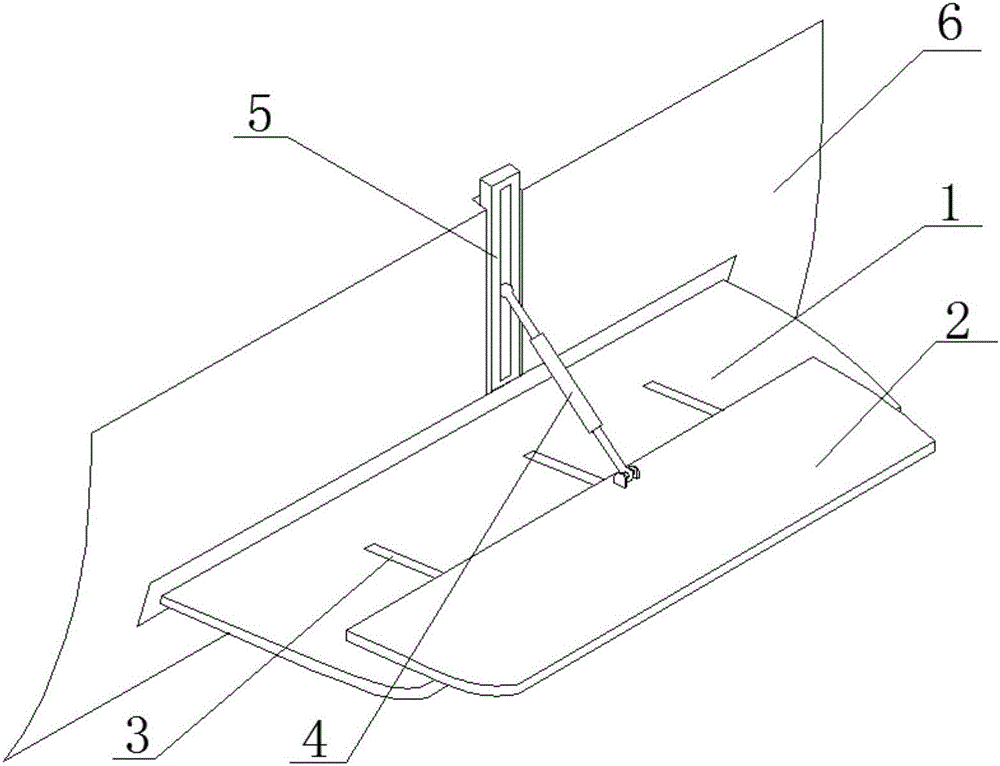

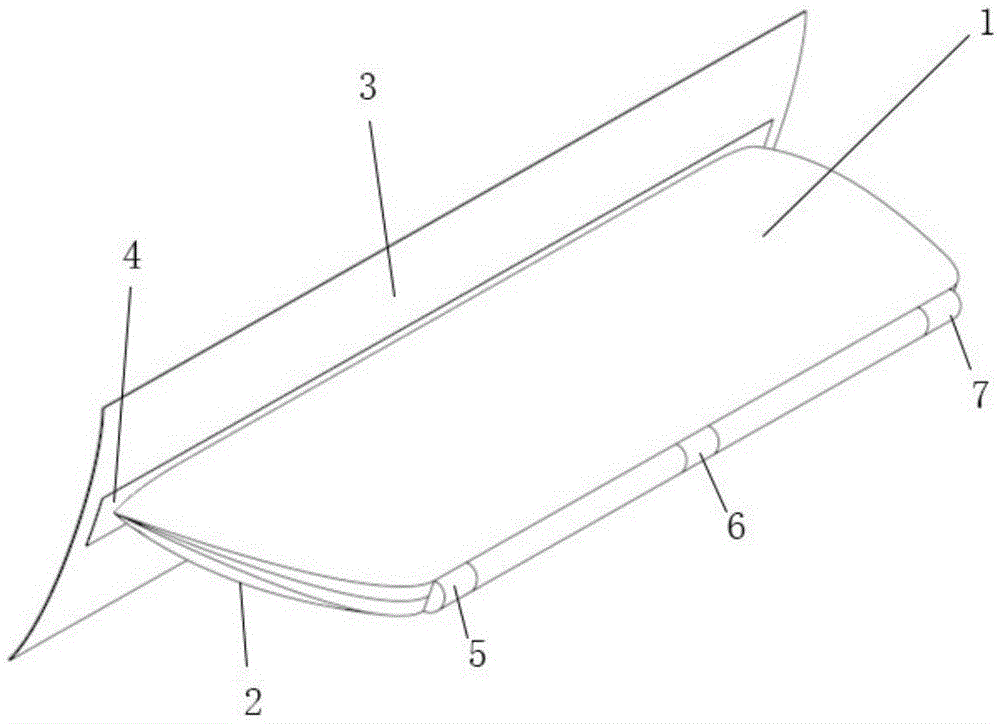

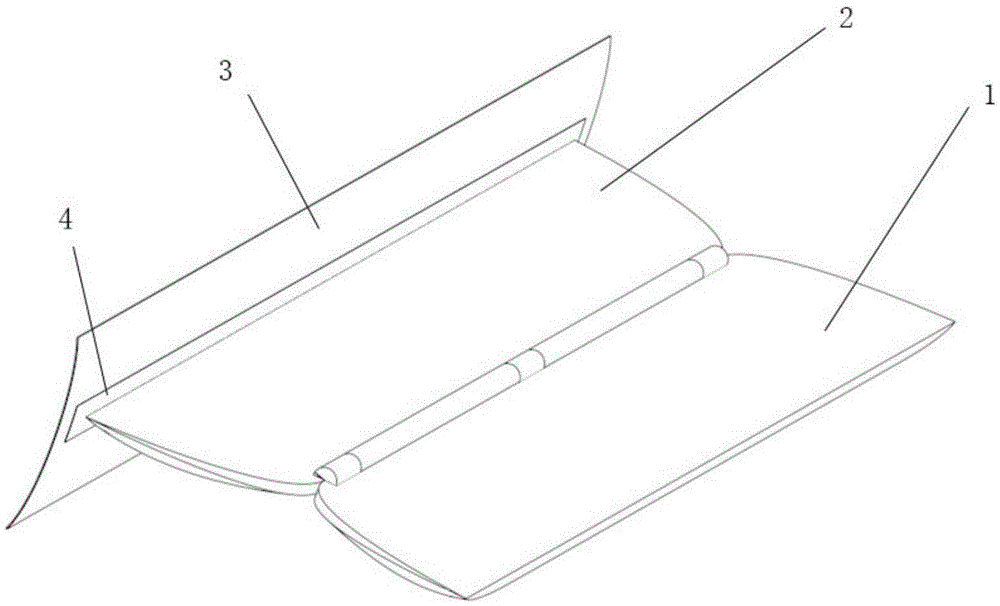

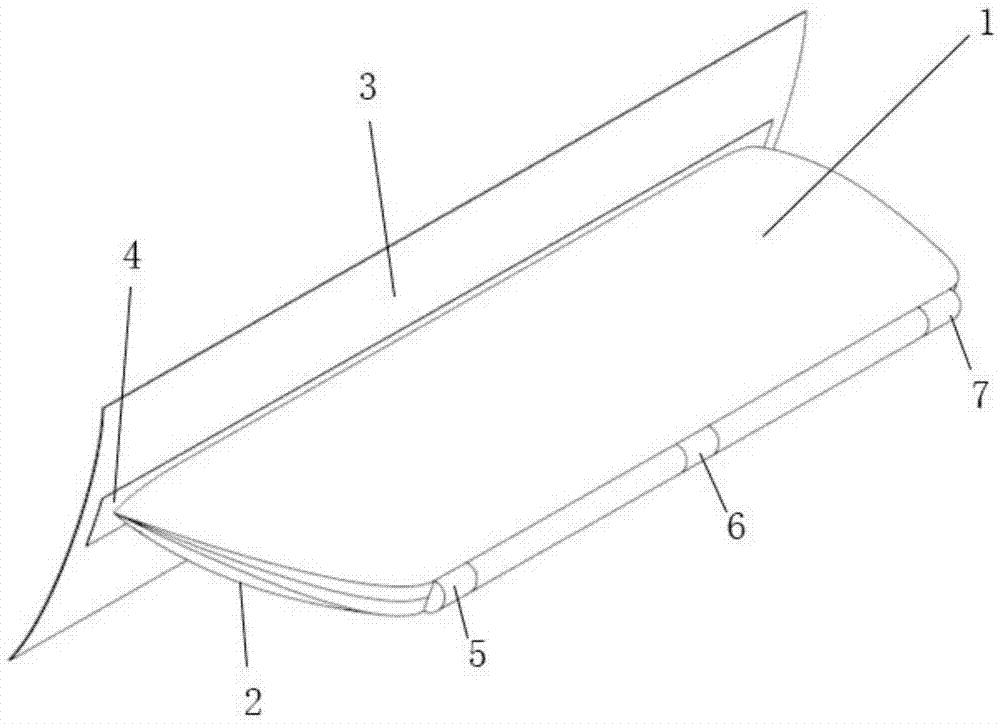

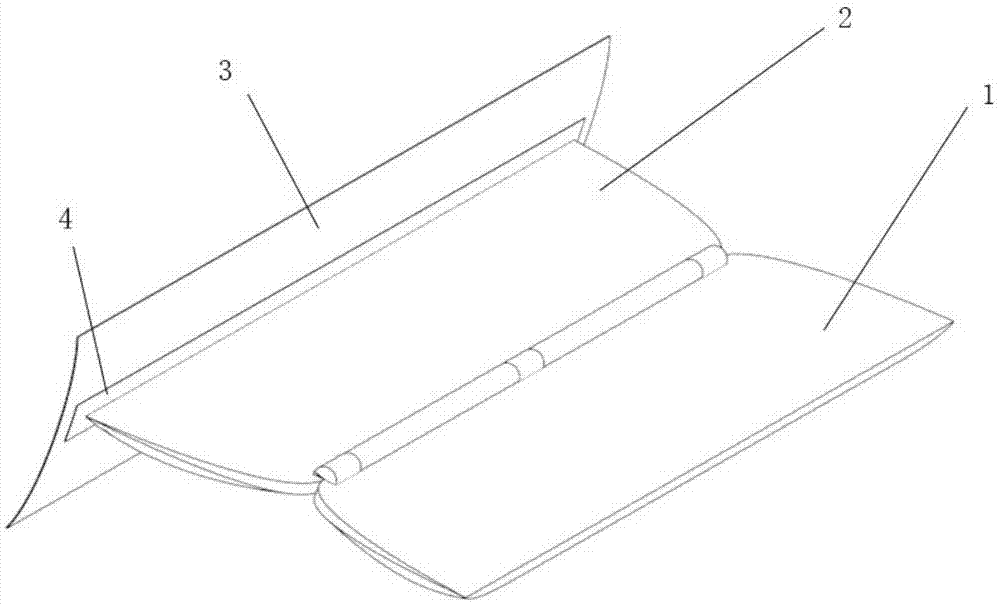

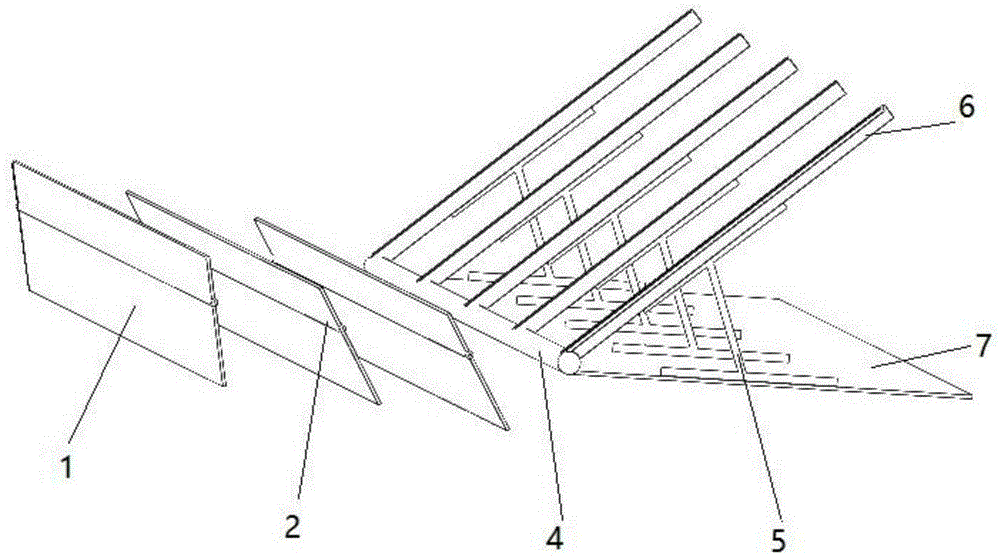

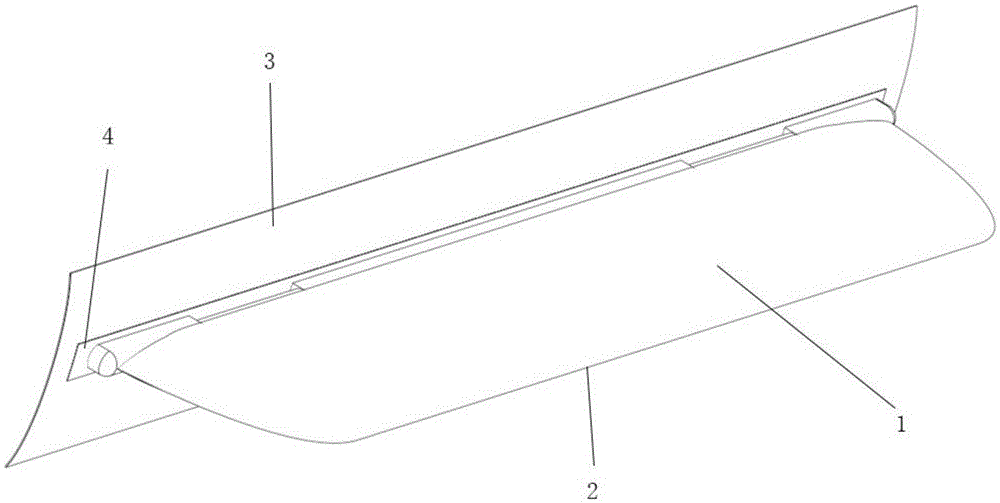

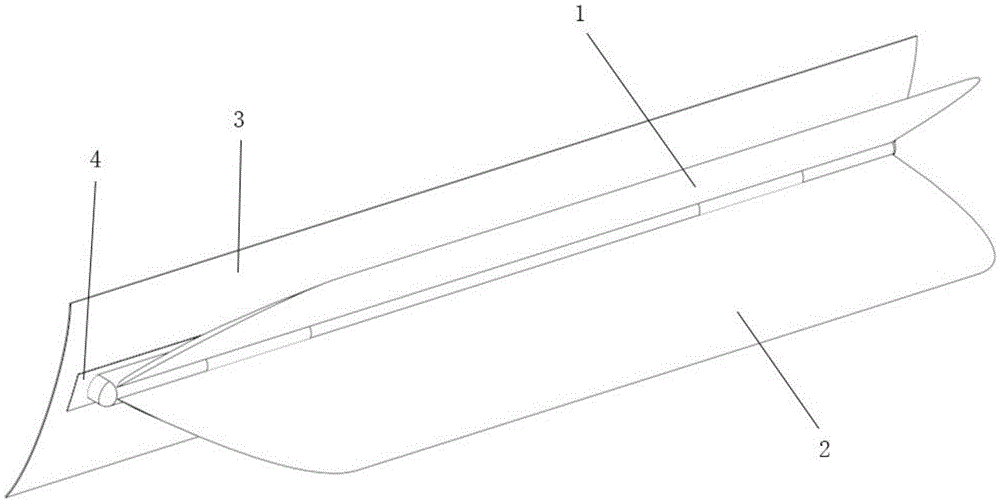

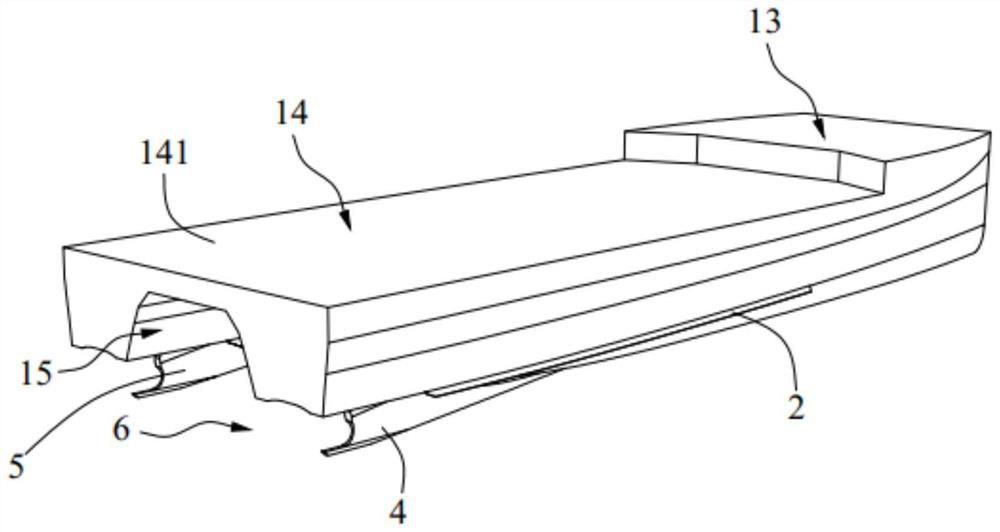

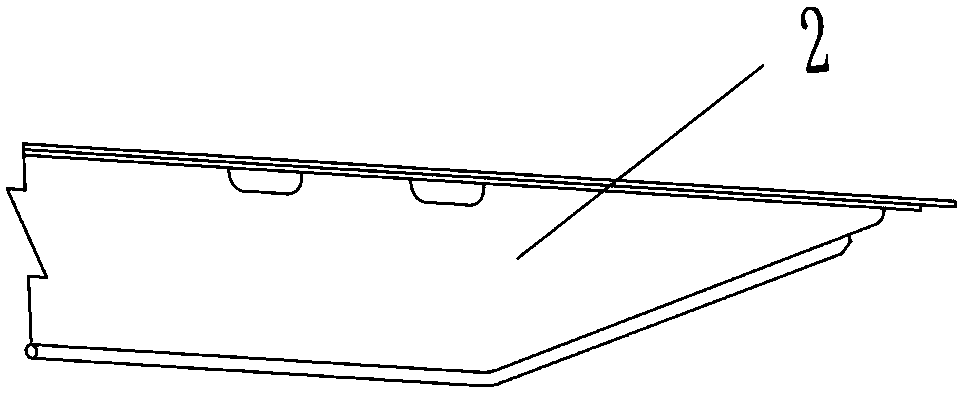

External-opened retractable bilge keel

InactiveCN105539757ADoes not affect speedIncrease dampingVessel movement reduction by foilsStrakeBilge

The invention relates to an external-opened retractable bilge keel. A main body structure comprises two parts of a fixed shell structure (2) and a rotary shell structure (1), wherein after being closed, the two parts are in a flat shape; front and tail ends of the main body structure is shaped like a streamline; the fixed shell structure (2) is fixedly connected with a bilge strake (3); the rotary shell structure (1) is connected with the fixed shell structure (2) through a rotating shaft system; and the rotating shaft system is used for opening and closing the shell structure (1). The external-opened retractable bilge keel provided by the invention is advantaged in that the rolling damping of a ship can be increased, the rolling of the ship is effectively reduced and the rolling stability is enhanced.

Owner:TIANJIN UNIV

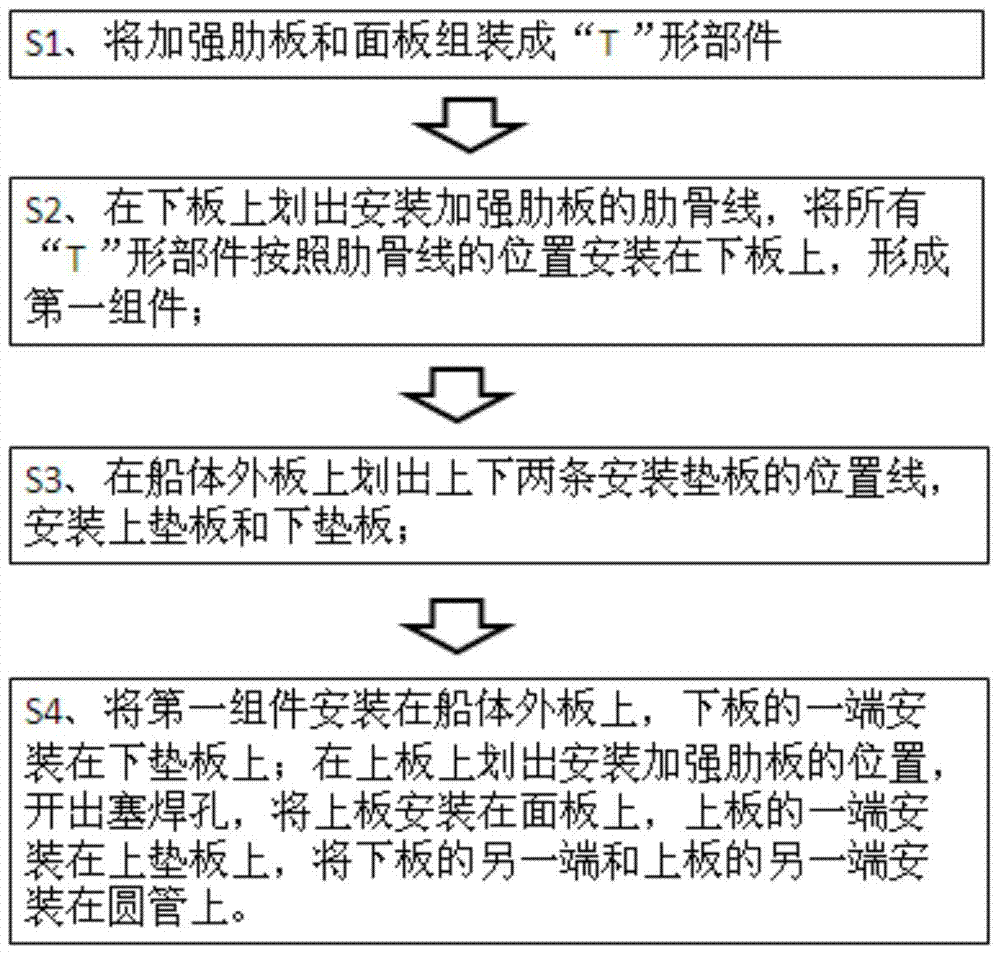

Mounting and positioning method for bilge keel

ActiveCN106985966AImprove the anti-shake effectSuppress rollVessel movement reduction by foilsVessel designingMarine engineeringKeel

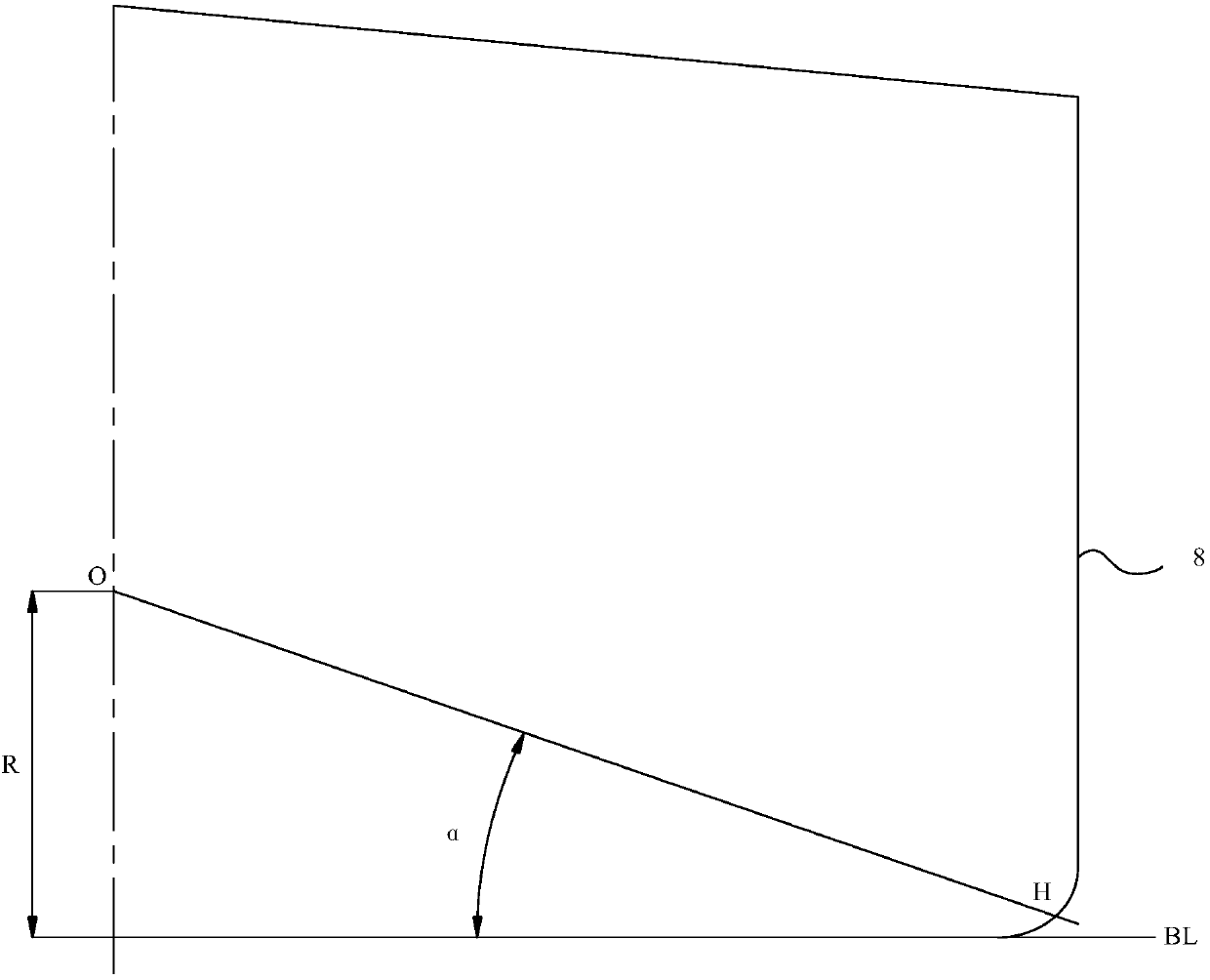

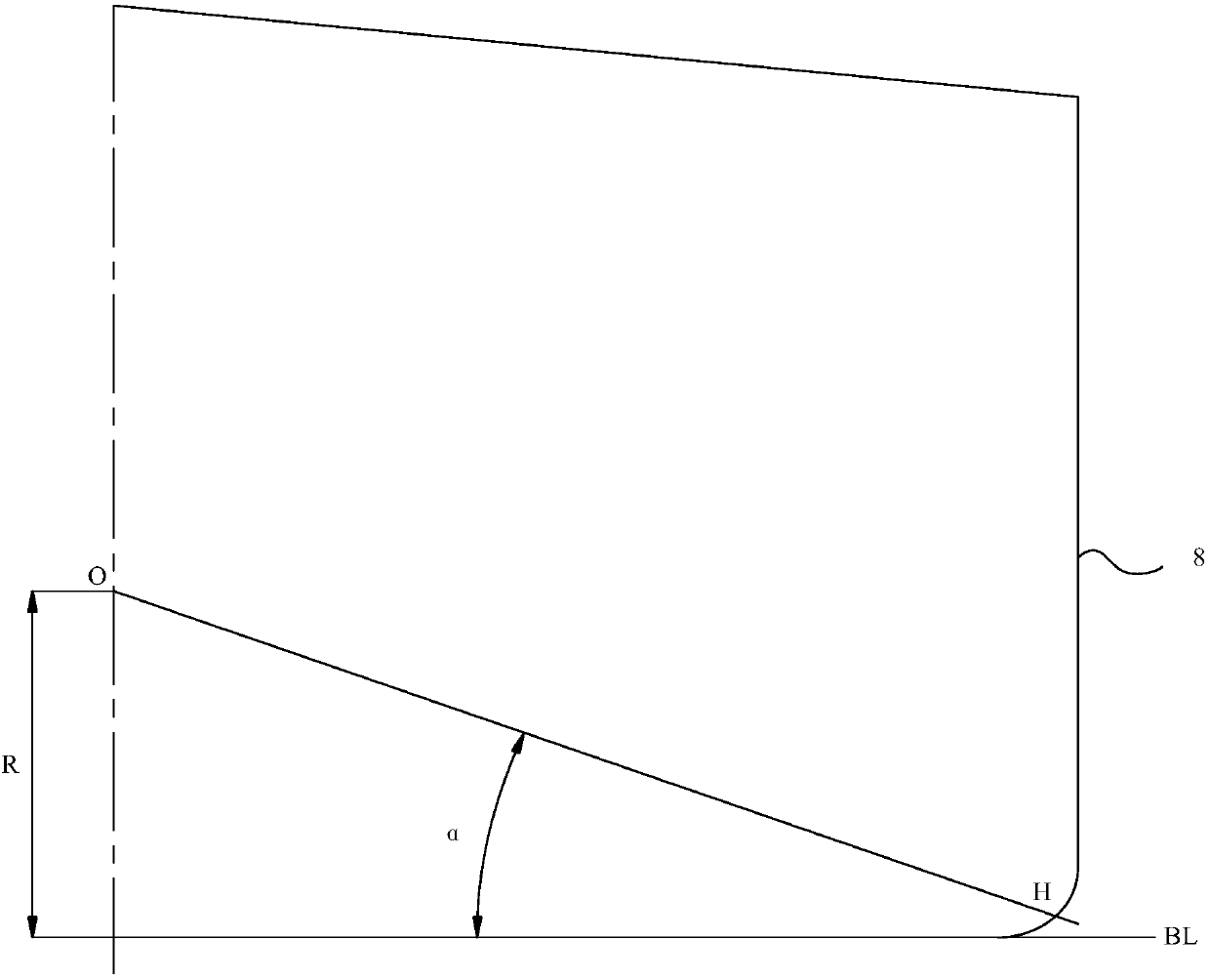

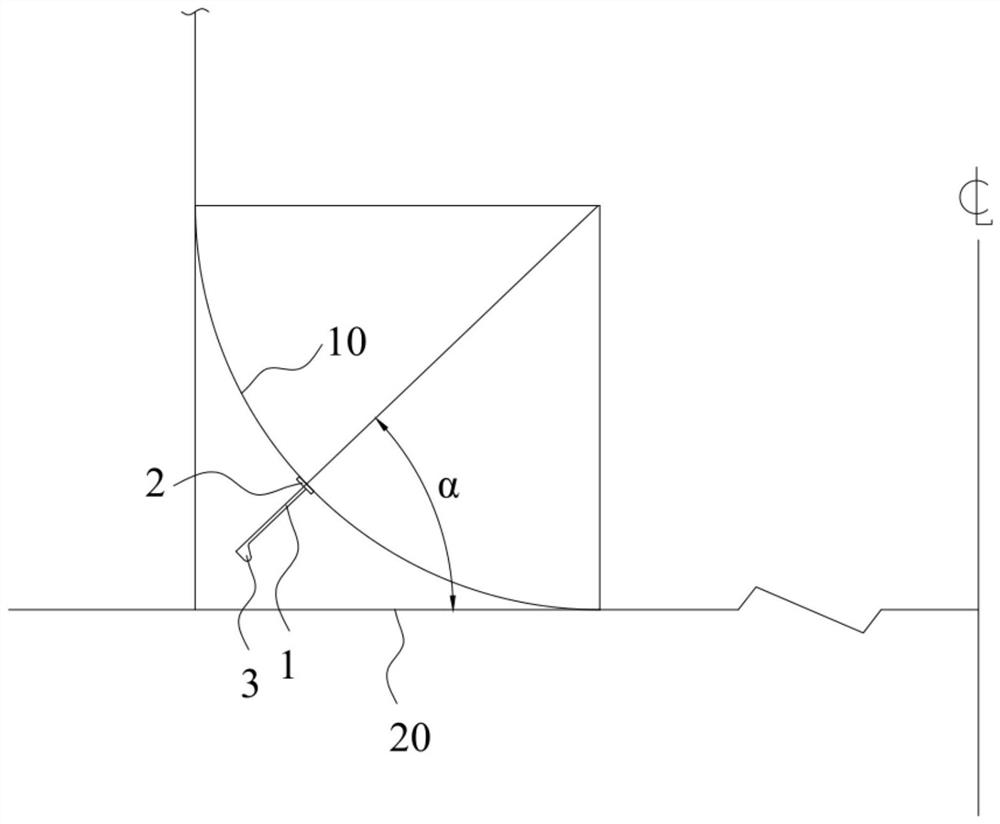

The invention discloses a mounting and positioning method for a bilge keel. The method comprises the following steps that S1, in a cross section drawing of a hull, a mounting point of the bilge keel and a rolling central point of a ship are connected; S2, the angle formed by a connecting line of the mounting point of the bilge keel and the rolling central point of the ship and a base line is the positioning angle of the bilge keel, wherein the base line is a tangent line of the cross section of the hull and the inner surface of a ship bottom plate; and S3, the bilge keel is mounted according to the positioning angle of the bilge keel. The height R of the rolling central point from the base line is calculated according to the following formula: R=D / 4+T / 2, wherein D is the molded depth, and T is the draft of the ship under the ballast working condition. The operation working condition with the most severe rolling serves as a preferred working condition for determining the positioning angle of the bilge keel so as to determine the positioning angle of the bilge keel, so that severe rolling of the working condition can be restrained in a maximum mode, meanwhile, rolling of other working conditions also can be restrained, and accordingly the bilge keel reaches a good overall rolling reducing effect.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

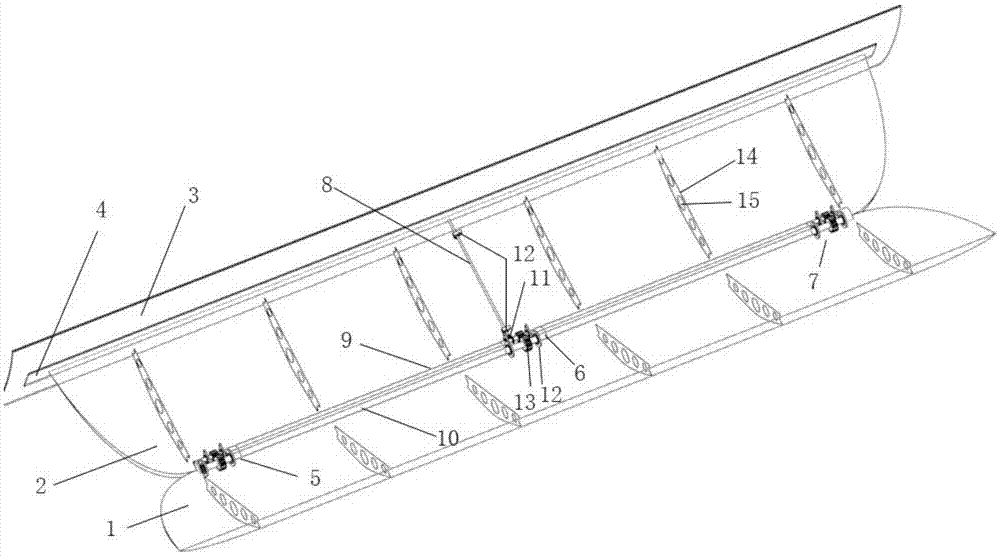

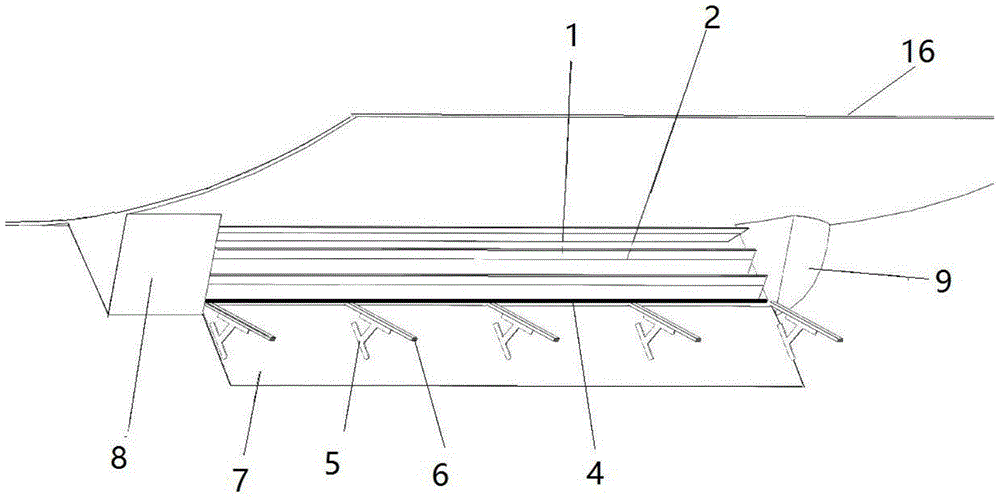

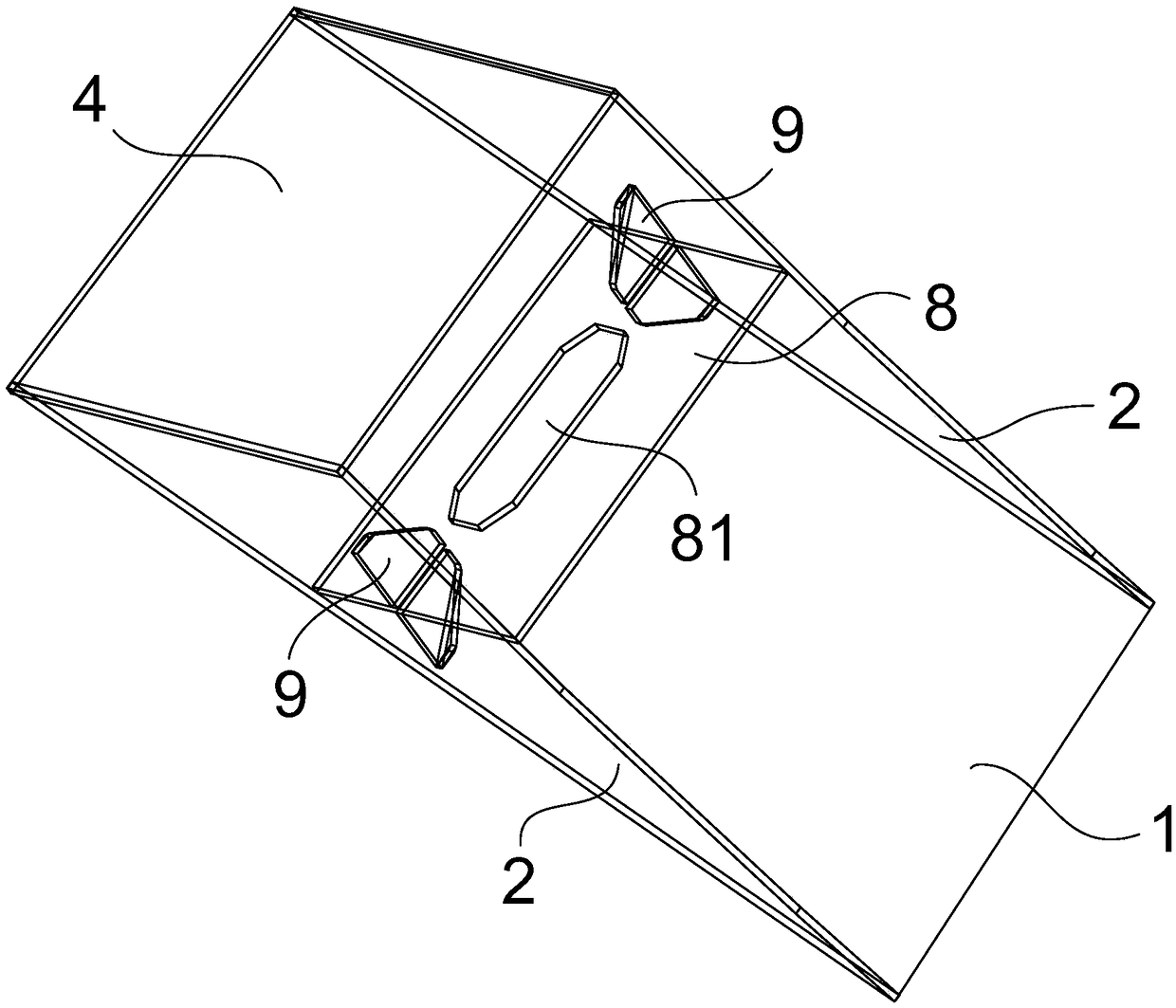

Foldable bilge keel with groove-shaped base plate

ActiveCN105083466AAvoid destructionIncrease roll dampingBilge keelsEngineeringMechanical engineering

The invention discloses a foldable bilge keel with a groove-shaped base plate. The foldable bilge keel comprises the base plate and a rotary plate. The base plate is formed by connecting two structural styles, namely, base plate convex plates and base plate concave plates, in a staggered mode. A shaft sleeve is welded to the outer edge of the base plate, and a rotary shaft is arranged in the shaft sleeve. The rotary plate is composed of an inner plate and a cover plate, one end of the inner plate and one end of the cover plate are in rigid connection with the rotary shaft, the inner plate and the cover plate are arranged in a V shape, the inner plate is formed by connecting two structural styles, namely, inner plate convex plates and inner plate concave plates, in a staggered mode, the inner plate convex plates and the inner plate concave plates correspond to the base plate convex plates and the base plate concave plates in position, and therefore the inner plate can be attached to the base plate after rotating around the rotary shaft. The cover plate is a flat and straight plate, a front supporting box and a rear control box are fixed to the two ends of the rotary shaft through shaft sleeves in a welded mode, the shaft sleeves are rotatably connected with the rotary shaft, a rotary shaft driving device is arranged in the rear control box, and the rotary shaft is connected with the rotary shaft driving device. According to the structure, a folding state can be adopted in a limited channel or small wind waves, and damage such as grounding and collisions is avoided.

Owner:北京传奇优声文化传媒有限公司

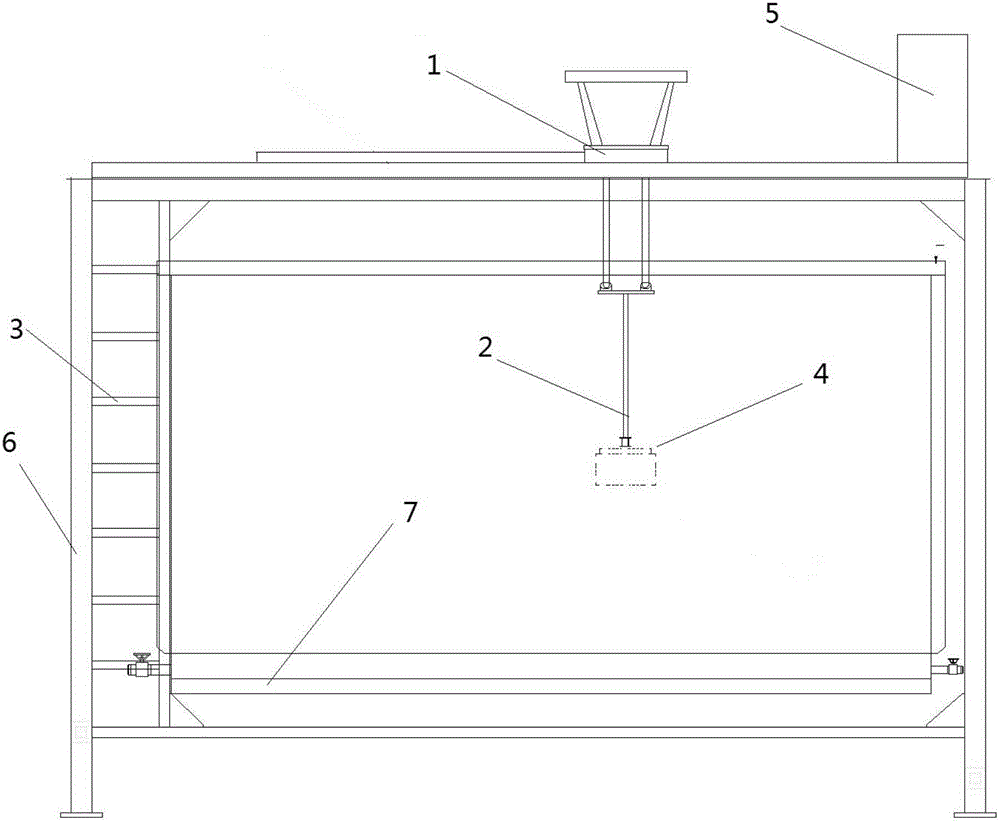

Ocean structure fine model viscosity performance test platform

InactiveCN105865976AReduce spanReduce vibrationFlow propertiesHydrodynamic testingBilgeMulti degree of freedom

The invention discloses an ocean structure fine model viscosity performance test platform. The ocean structure fine model viscosity performance test platform comprises a water tank with the upper portion open, a transmission rod and a multi-degree-of-freedom moving mechanism, wherein the lower end of the transmission rod can be connected with a test model and stretches into the water tank, and the multi-degree-of-freedom moving mechanism is connected to the upper end of the transmission rod and can drive the transmission rod to carry out front-back translational movement, vertical translational movement, front-back swing movement and left-right swing movement. The test platform enables the test model to simulate surging, heaving, pitching and yawing movement of a ship, and is suitable for viscosity hydrodynamic performance study of various ocean structures such as heaving plates, bilge keels, anchor chains, vertical pipes and tension legs.

Owner:SHANGHAI JIAO TONG UNIV

Glass fiber reinforced plastic ship bilge keel installation method

The invention discloses a glass fiber reinforced plastic ship bilge keel installation method. The method includes the steps that a hull mold is provided with a horizontally-marked groove, and a boss in the shape the same as that of a bilge keel installation face is installed at a bilge keel installation position; a hull is prefabricated, and a steel plate is arranged at the bilge keel installation position and clamped in the prefabricated glass fiber reinforced plastic hull; a bilge keel is prefabricated, and a connecting steel plate is arranged on a bilge keel connecting end face; mold release is conducted, and the bilge keel is installed in a bilge keel installation groove in the hull; a drill bit is used for drilling the hull, the prefabricated steel plate in the glass fiber reinforced plastic hull and the steel plate on the bilge keel connecting end face from the inner side of the hull, and connecting threads are tapped on through holes in the steel plate on the bilge keel connecting end face; single-end bolts are adopted to penetrate the prefabricated steel plate in the glass fiber reinforced plastic hull from the inner side of the hull to be in threaded connection with the steel plate on the bilge keel connecting end face; and a gap between the bilge keel and the hull is pasted through glass fiber reinforced plastic, and surface treatment is conducted. The method has the beneficial effects that localization is accurate, installation is convenient, the connecting strength is high, and a use effect is good.

Owner:WEIHAI ZHONGFU XIGANG SHIP

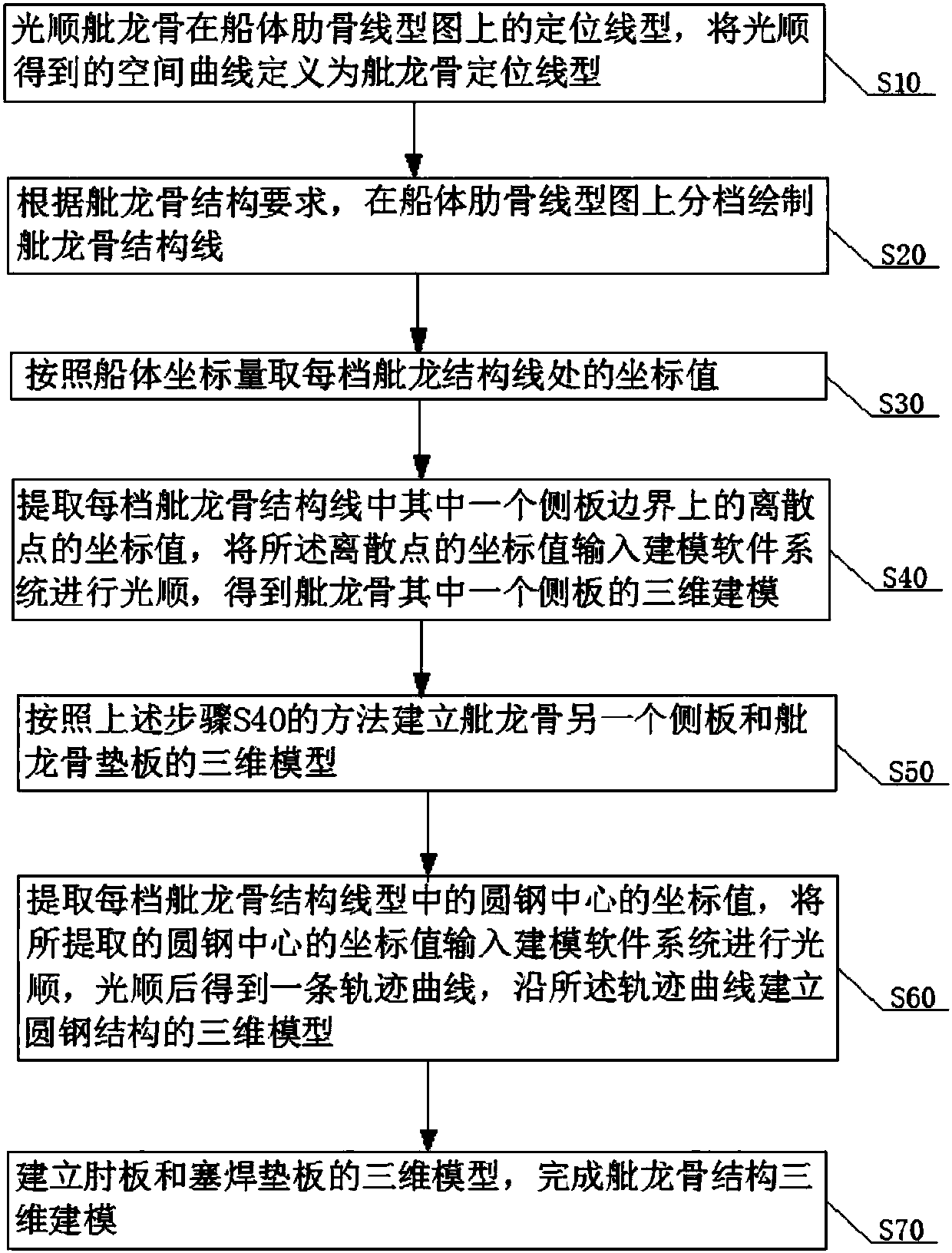

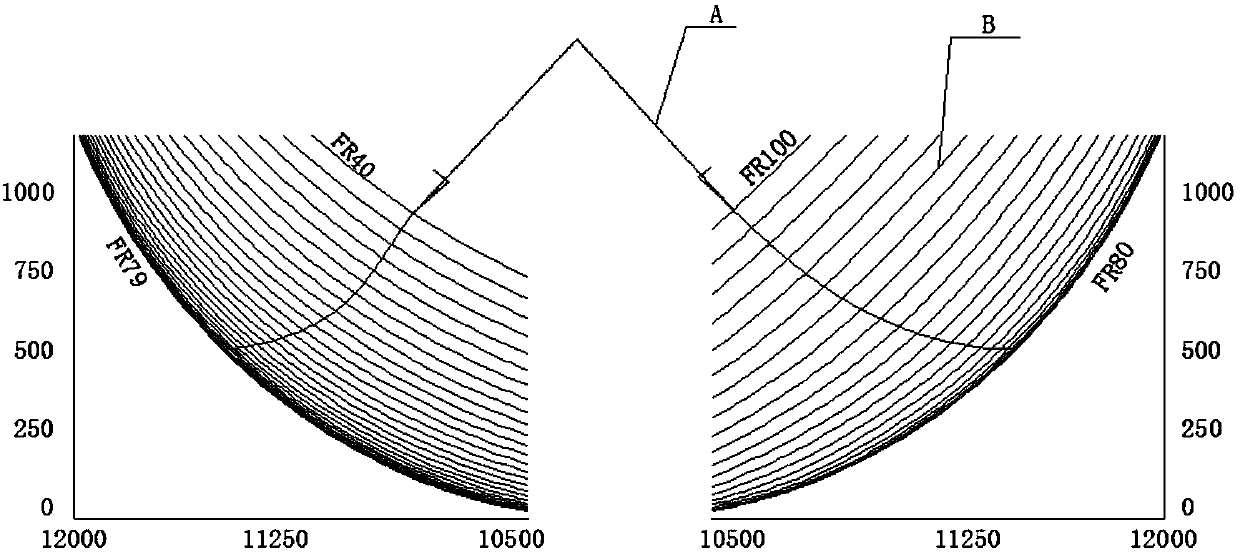

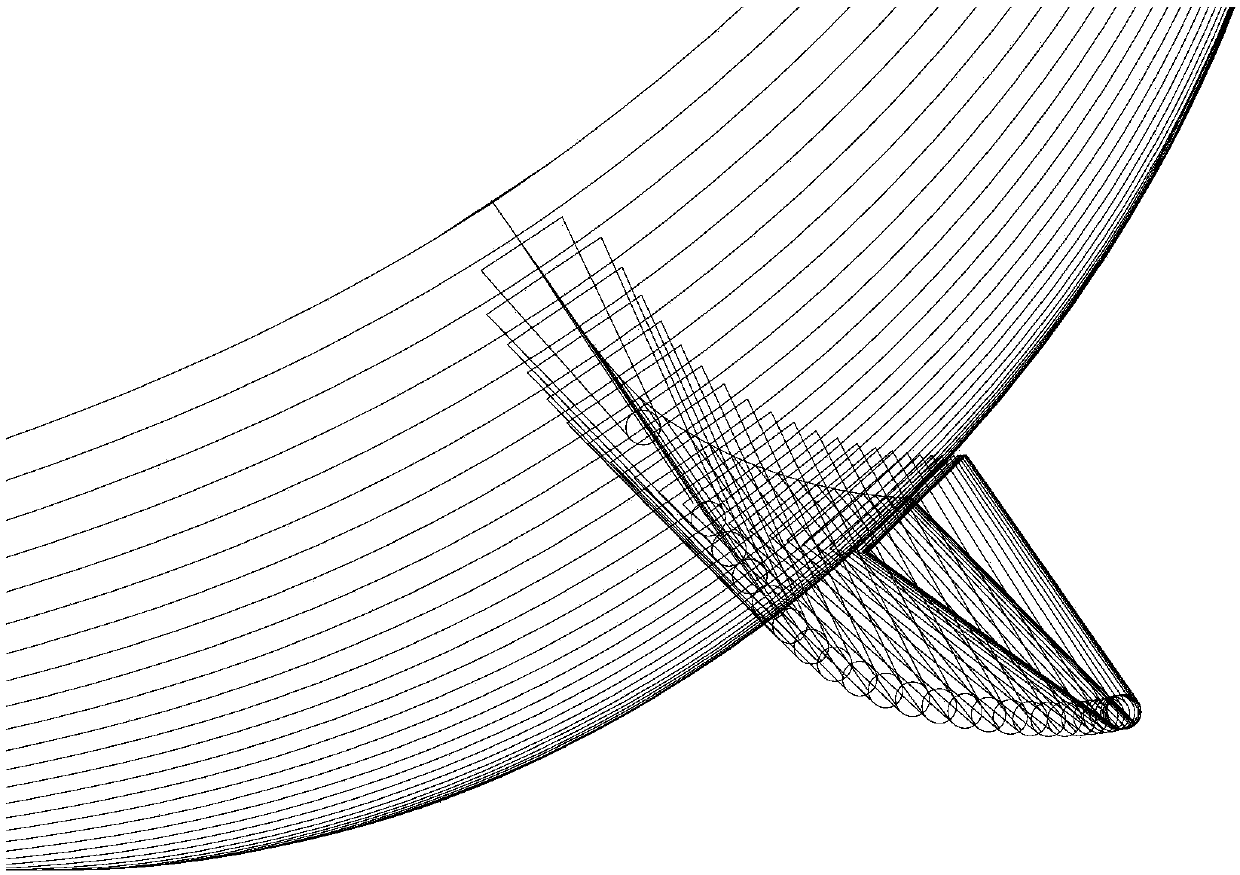

Three-dimensional modeling method for bilge keel structure and bilge keel structure

PendingCN107818226A3D modeling realizationPrevent deviationGeometric CADDesign optimisation/simulationKeelSimulation

The invention relates to a three-dimensional modeling method for a bilge keel structure and the bilge keel structure. The three-dimensional modeling method comprises the following steps: performing graded drawing on bilge keel structure lines according to structural features of the bilge keel; measuring coordinate values at each grade of the bilge keel structure lines; and inputting the coordinatevalues of the acquired discrete points into a modeling software system for fairing, thereby obtaining the three-dimensional model of the bilge keel structure which meets the actual operating requirements and is matched with the ship hull plate. According to the method disclosed by the invention, three-dimensional modeling of the bilge keel is realized, the integrity of the ship body structure model is improved, deviation of the parts of the bilge keel structure caused by manual lofting is avoided, and the structure precision is increased. In addition, the three-dimensional model of the bilgekeel structure obtained by the method can directly participate in calculation of ship weight center of gravity, and the calculation accuracy is improved. Meanwhile, the structural parts are accuratelyand rapidly expanded by the model, and the operating efficiency is increased.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

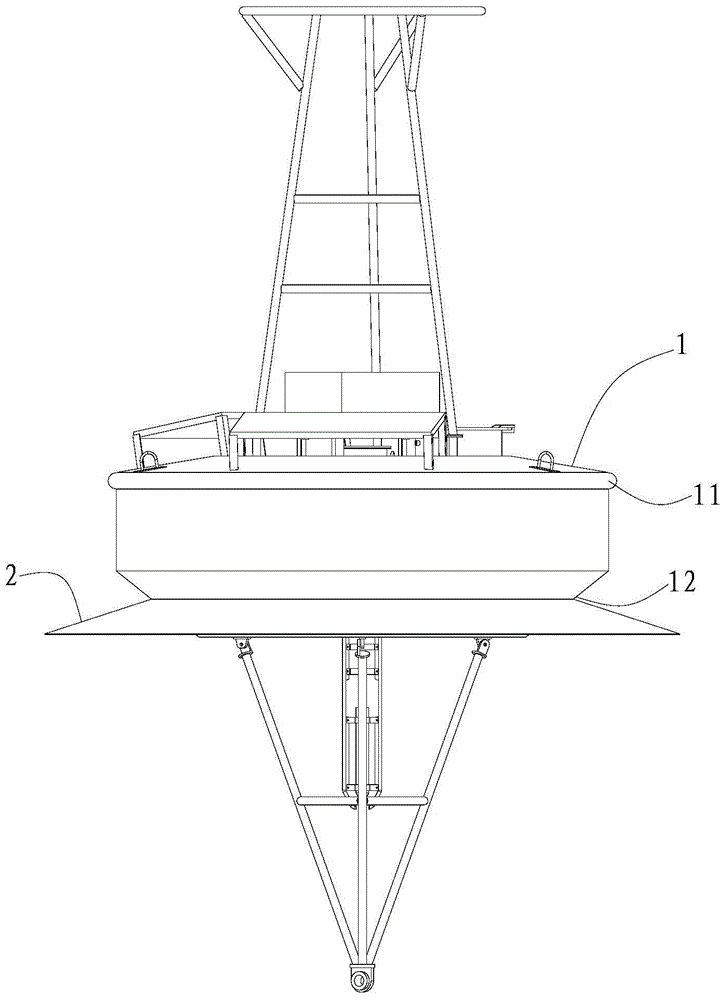

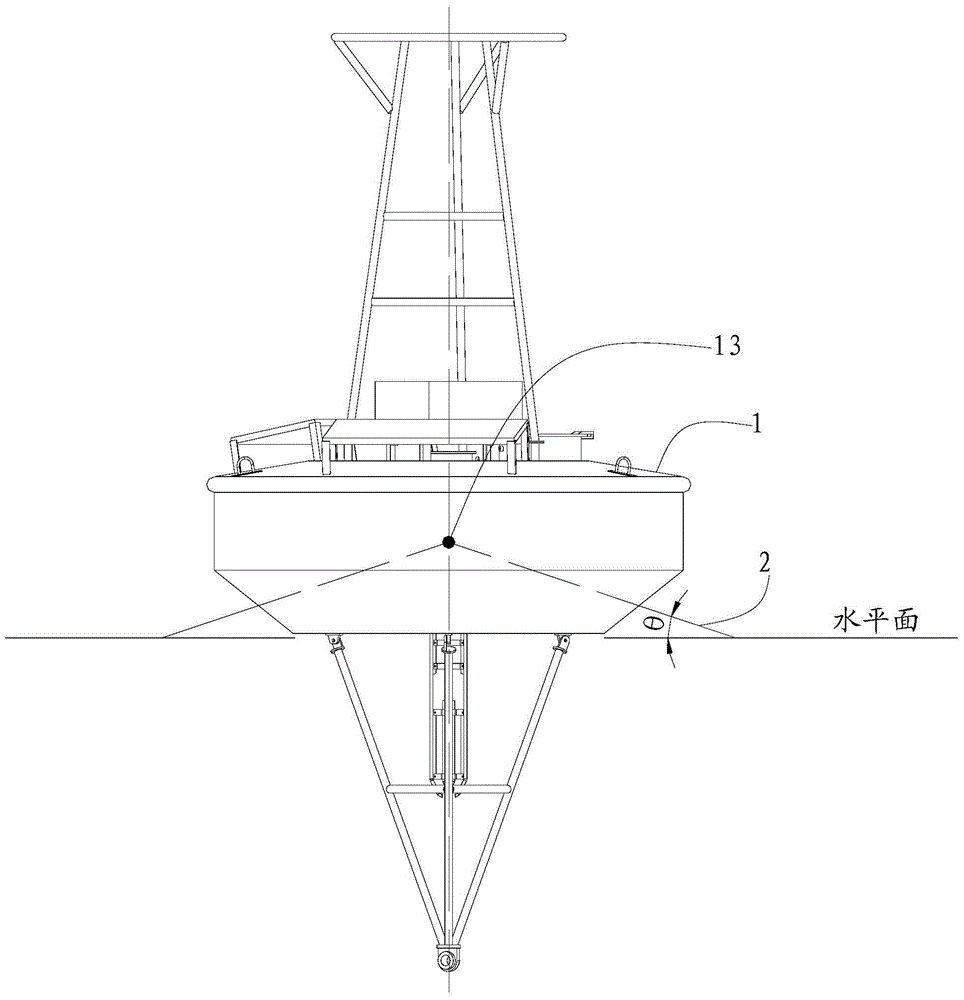

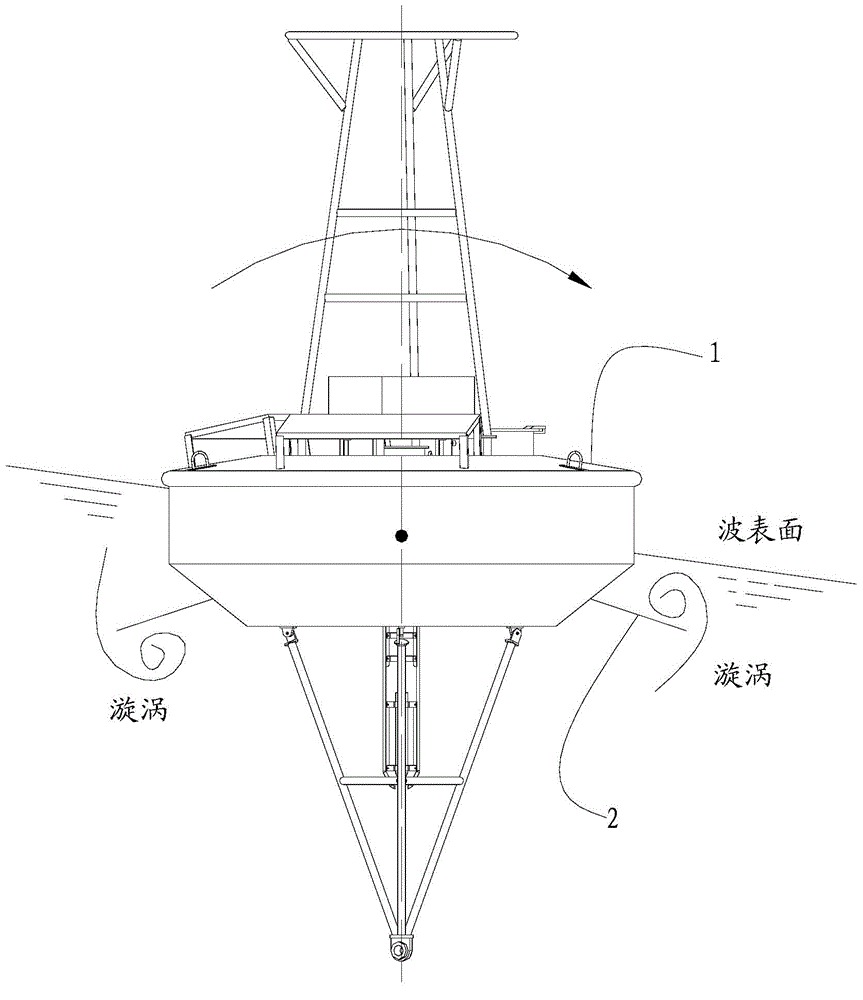

Stabilizing device of buoy

InactiveCN104875851AReduce swingEasy and reliable replacementWaterborne vesselsBuoysKeelWeb structure

A stabilizing device of a buoy comprises bilge keels which are annularly arranged on the bilge part of the buoy at 360 degrees, the included angle between each bilge keel and the horizontal panel is 15-30 degrees, and the extension lines of the bilge keels pass the gravity center of the buoy. The width of the bilge keels is 4%-6% of the diameter of the disk-shaped deck face of the buoy. The bilge kneels can be of a single-web structure or a double-web structure. The stabilizing device can reduce swings of the buoy along with waves, and the buoy is more convenient and reliable to use when an instrument is replaced and maintained. The stabilizing device is simple in structure and low in production cost.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

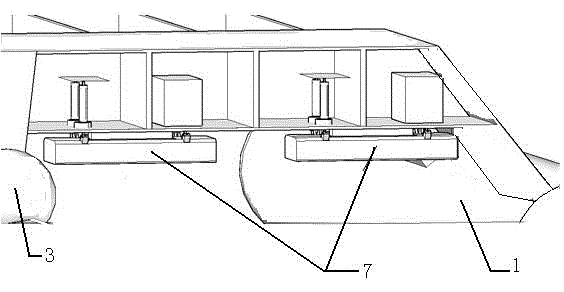

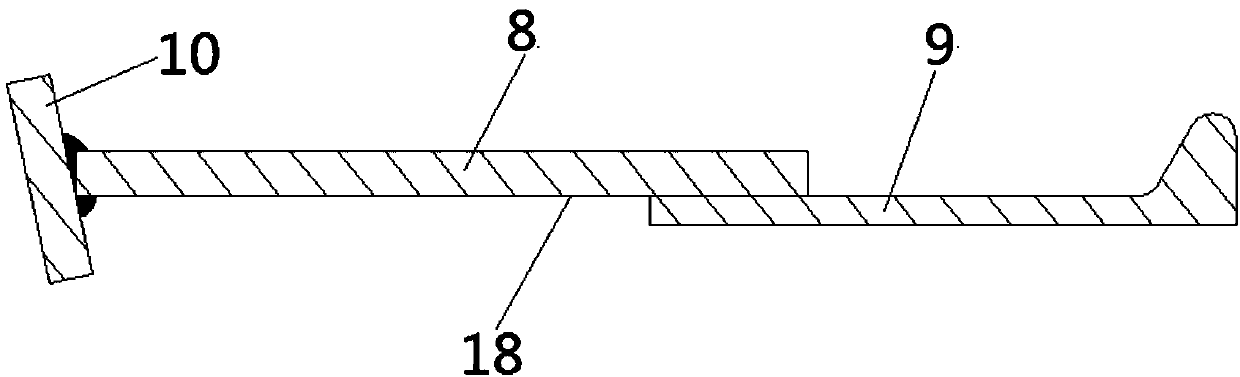

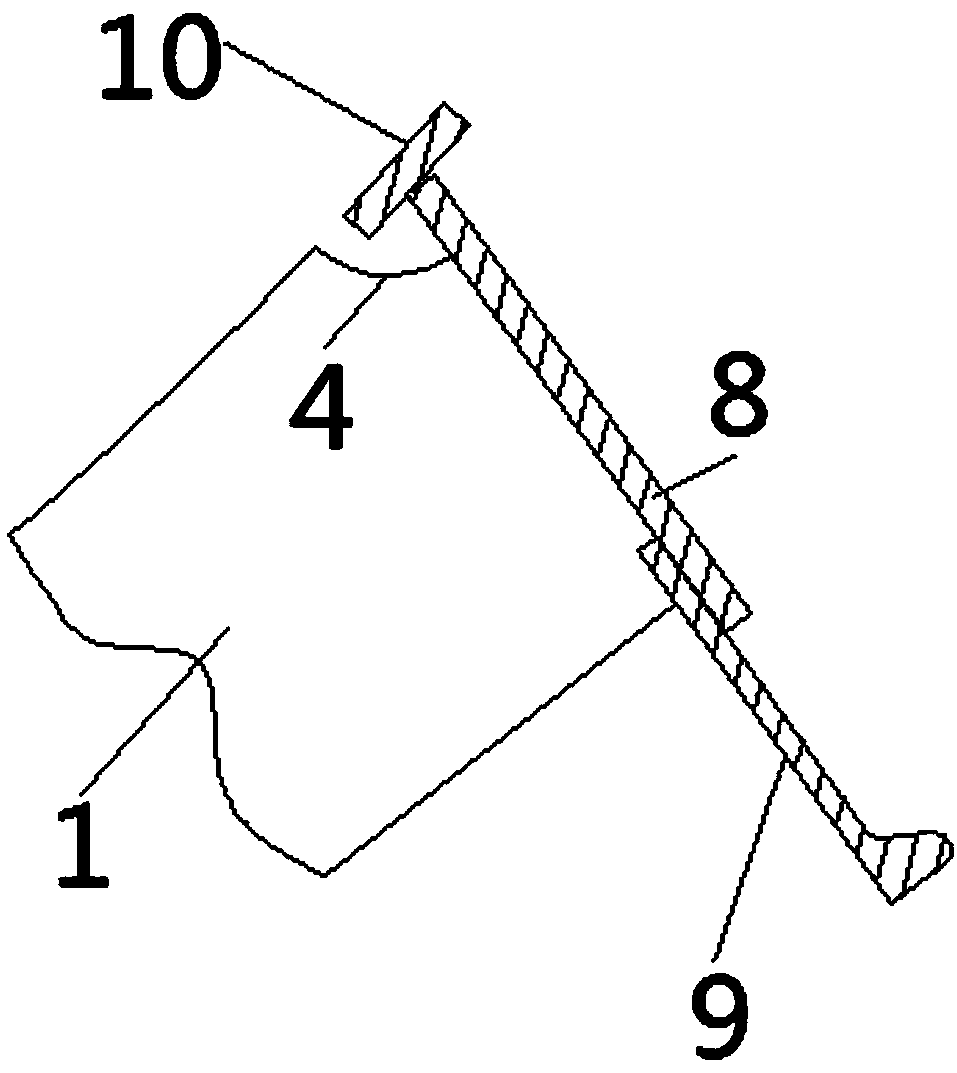

Ship retractable type bilge keel device using guide rails

The invention provides a ship retractable type bilge keel device using guide rails. A bilge keel main board is welded to a ship body and is provided with marching guide rails which are internally provided with a retractable type auxiliary board; the middle position of the retractable type auxiliary board is hinged to one end of a double-head hydraulic push rod; driving guide rails are arranged along the bilge portion of the ship body and are internally provided with a hydraulic rod; and the end portion of the hydraulic rod is hinged to the other end of the double-head hydraulic push rod. According to the ship retractable type bilge keel device using the guide rails, the bilge keel width is expandable, the structure is simple, the size is small, and the ship retractable type bilge keel device using the guide rails is especially suitable for large and middle type ships limited in bilge portion space.

Owner:HARBIN ENG UNIV

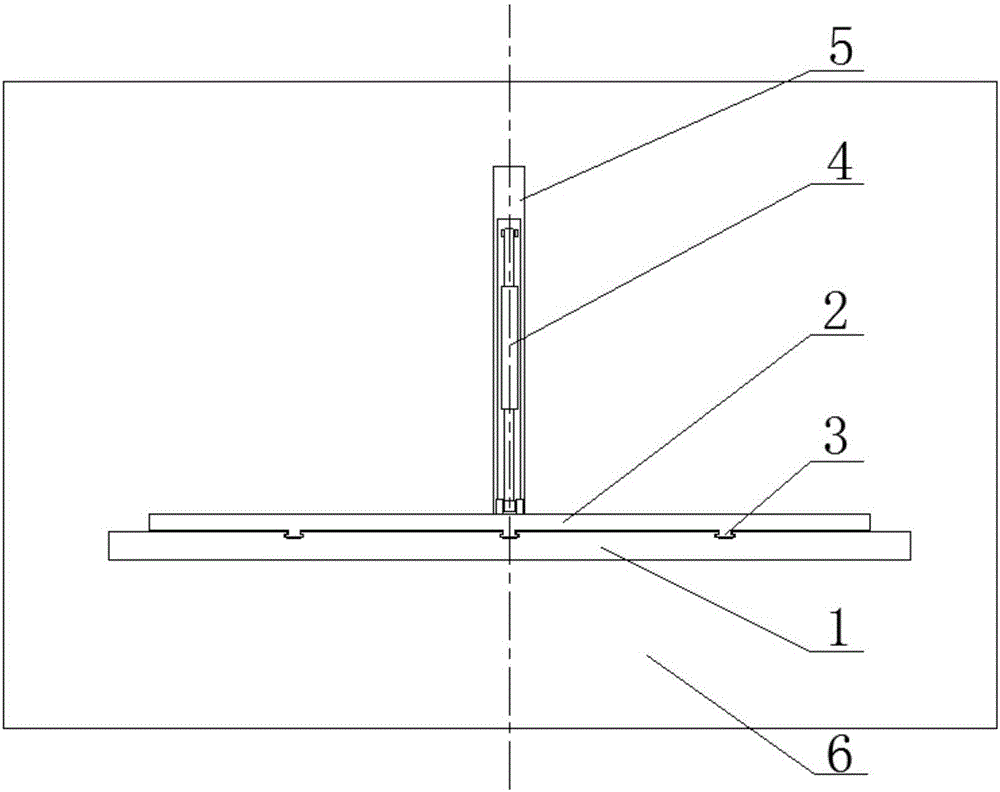

Control method for clam-shaped bilge keel

InactiveCN105539758ADoes not affect speedIncrease dampingVessel movement reduction by foilsLower limitShip stability

The invention relates to a control method for a clam-shaped bilge keel. A main body structure of the lam-shaped bilge keel comprises two parts of a fixed clamshell structure (2) and a rotary clamshell structure (1), wherein the rotary clamshell structure (1) is connected with the fixed clamshell structure (2) through a rotating shaft system. The control method comprises the following steps of monitoring a rolling angle, an angular velocity and an angular acceleration of a ship during ship navigation; obtaining ship draft information; checking ship stability variation; if any one of the three parameters of the rolling angle, the angular velocity and the angular acceleration continuously exceeds a corresponding safety threshold upper limit within a set time, driving the rotating shaft system by using a motor so as to unfold the rotary clamshell structure of the bilge keel; and if the three parameters of the rolling angle, the angular velocity and the angular acceleration are all continuously lower than corresponding safety threshold lower limits within a set time, driving the rotating shaft system by using the motor so as to fold the rotary clamshell structure of the bilge keel. According to the invention, the opening and closing of the bilge keel can be intelligently controlled.

Owner:TIANJIN UNIV

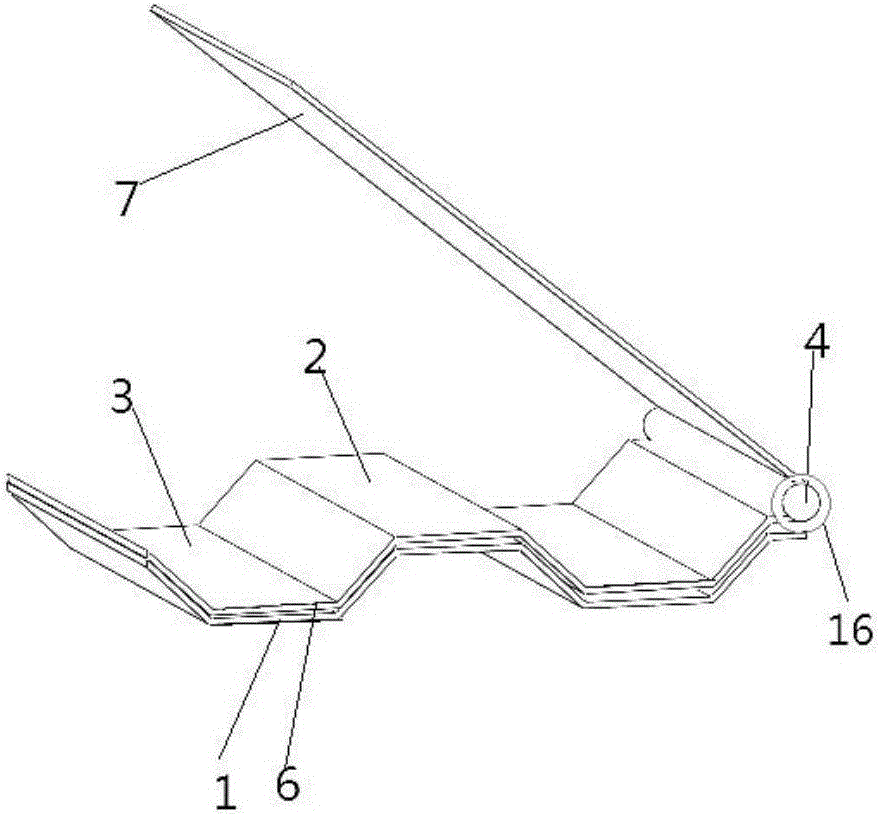

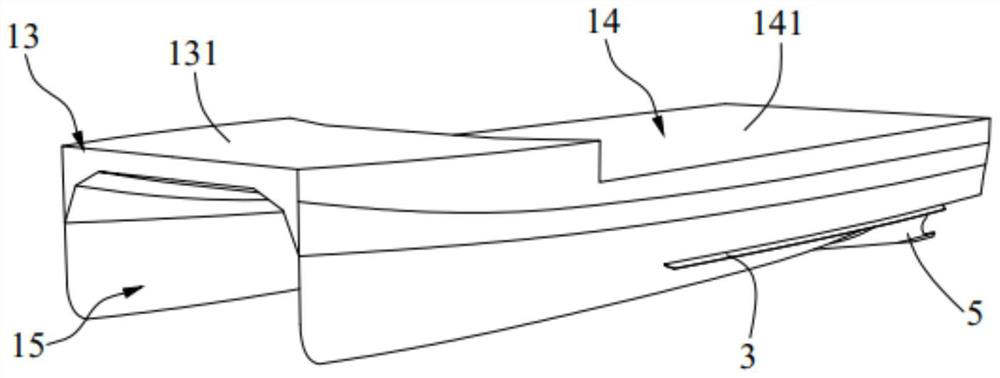

Bilge keel

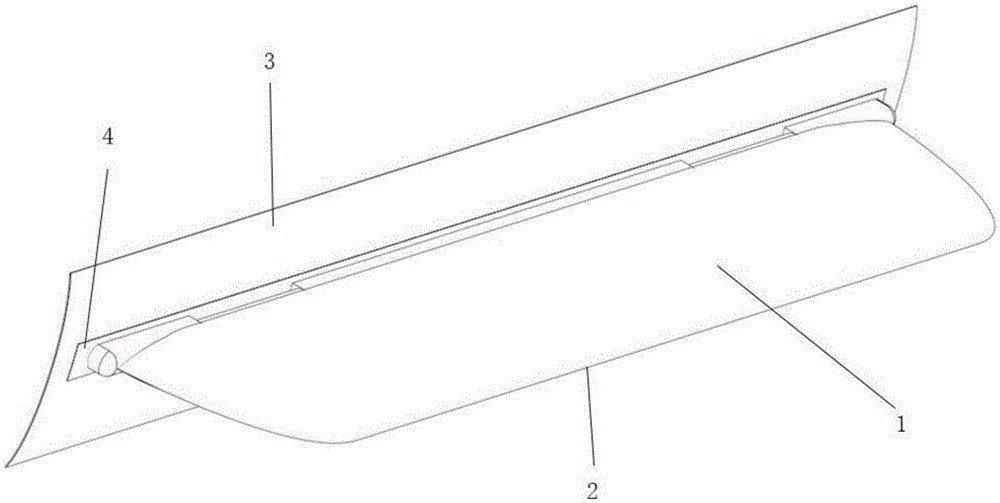

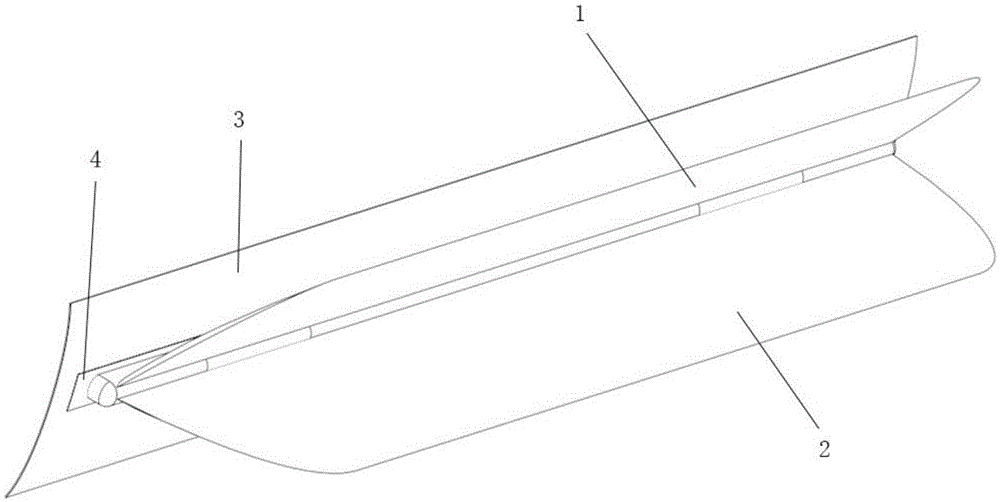

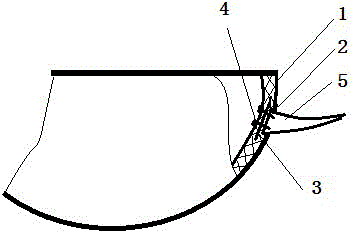

InactiveCN105438414ADoes not affect speedIncrease dampingBilge keelsVessel movement reduction by foilsStrakeBilge

The invention relates to a bilge keel. A body structure of the bilge keel comprises a fixed clamshell structure (2) and a rotary clamshell structure (1) which are in a flat shape after being combined; the head and tail ends are in a streamline shape; the fixed clamshell structure (2) is fixedly connected to a bilge strake (3); the rotary clamshell structure (1) is connected with the fixed clamshell structure (2) through a rotary shaft system; the rotary shaft system is used for opening and closing the rotary clamshell structure (1). The bilge keel can increase the rolling damping of a ship, effectively reduce rolling of the ship and enhance the rolling stability.

Owner:TIANJIN UNIV

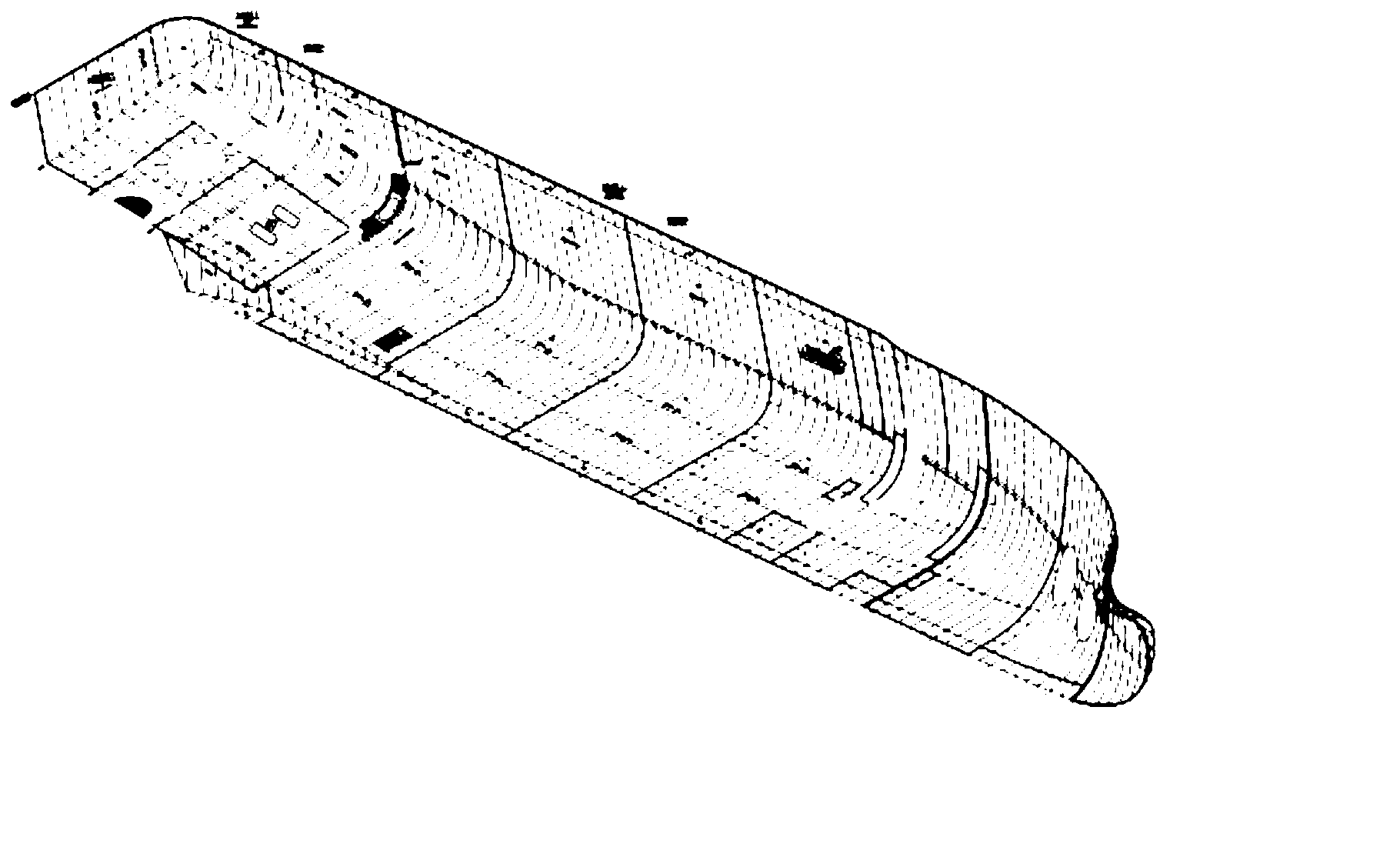

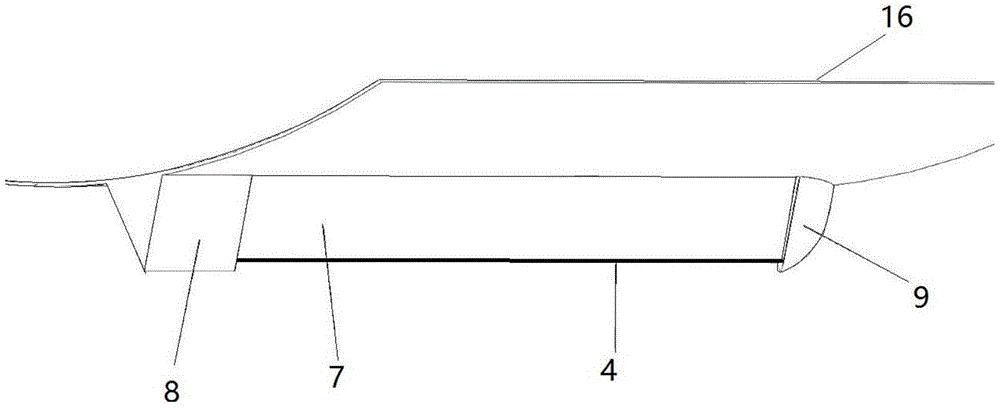

Bilge for ocean engineering auxiliary ship

The invention discloses a bilge for an ocean engineering auxiliary ship. A contour line at a parallel middle body segment of the bilge is folded corner-shaped. Through the folded corner-shaped bilge, the width of a bilge keel can be effectively increased, so that the roll damping is greatly increased; on the premise that an anti-rolling tank and an anti-rolling fin are not installed, the seakeeping performance of the ship is greatly increased, the construction difficulty of the ship is reduced simultaneously, and the construction cost of the ship is saved.

Owner:上海斯迪安船舶设计有限公司

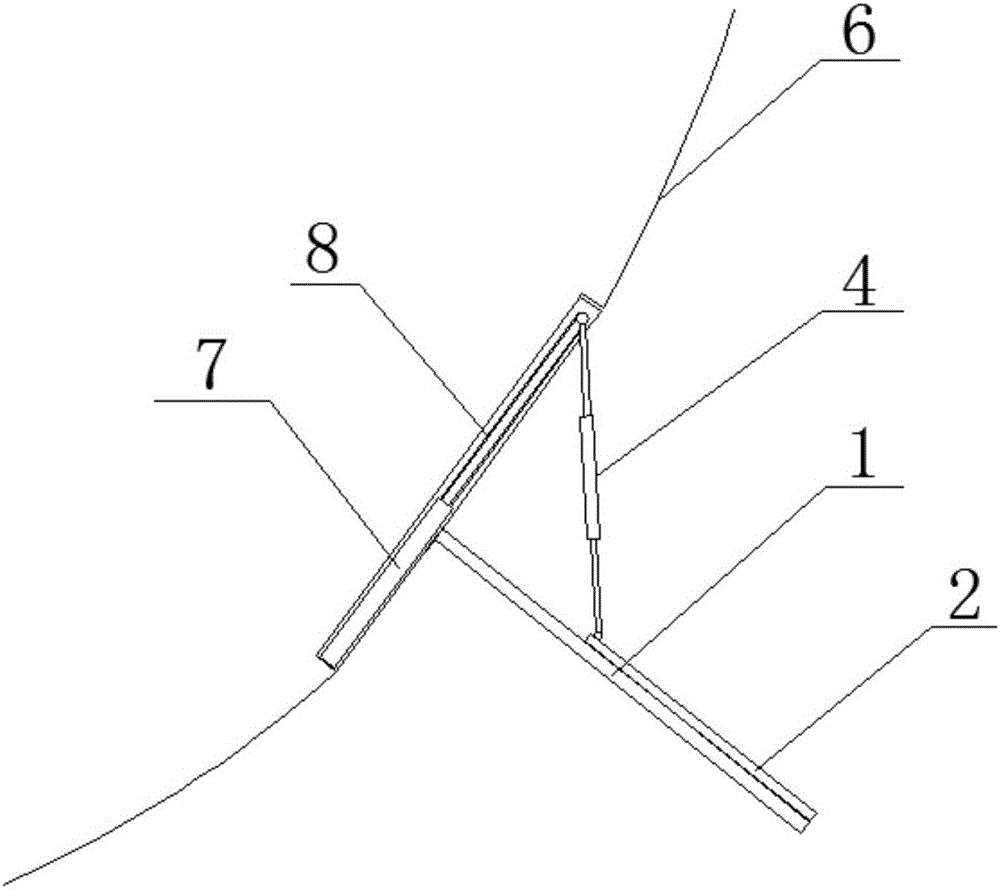

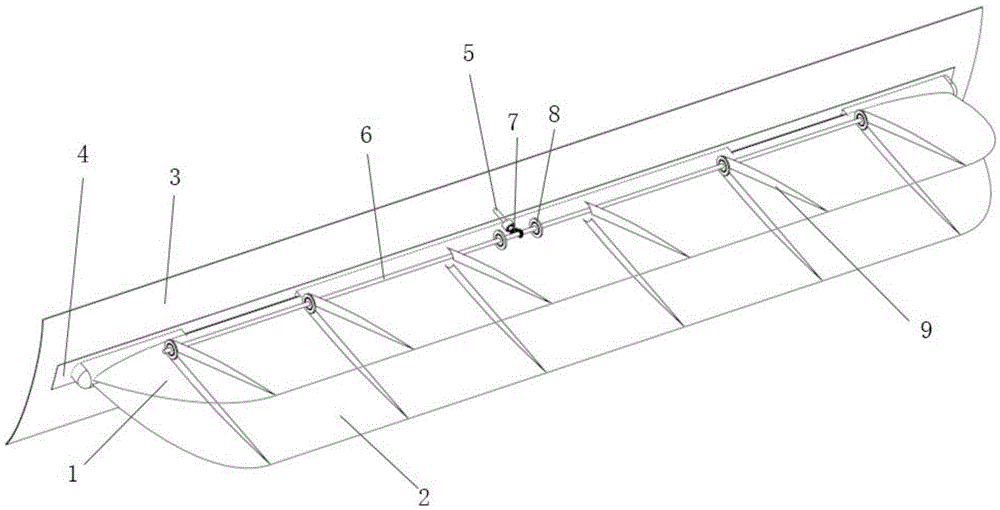

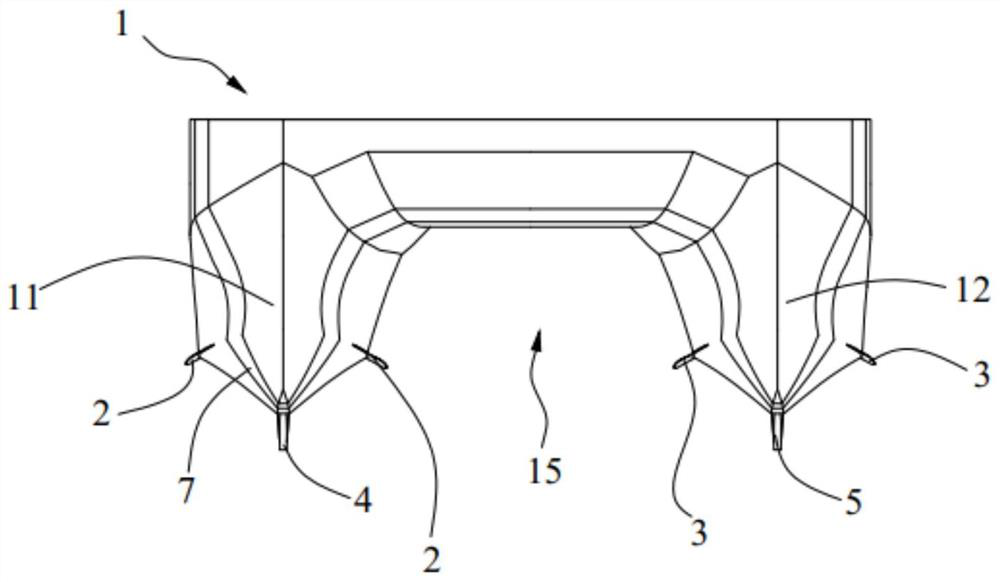

Rotary V-shaped bilge keel provided with guide vanes

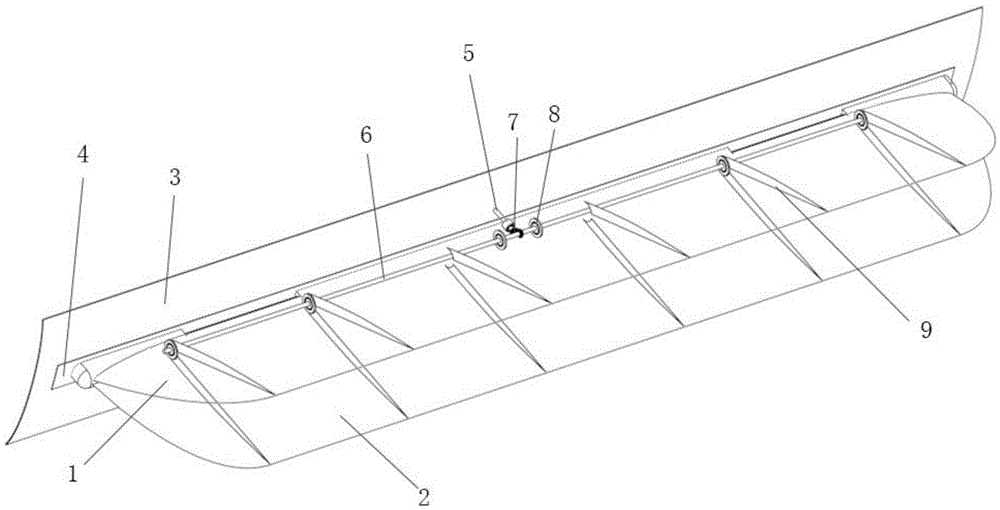

ActiveCN105197197AAvoid destructionIncrease roll dampingVessel movement reduction by foilsStrakeBilge

The invention discloses a rotary V-shaped bilge keel provided with guide vanes. The V-shaped bilge keel comprises a V-shaped rotary plate, wherein the V-shaped rotary plate comprises a V-shaped cover plate and a plurality of inner cross beams arranged in the same plane in parallel at intervals; the outer cover plate adopts a flat and straight plate, and one end of the outer cover plate and one end of each inner cross beam are jointly and fixedly connected with a rotating shaft; the outer cover plate and the inner cross beams are arranged in a V-shaped manner, a bow support box and a stern control box are arranged at two ends of the rotating shaft respectively and fixed on a ship bilge strake, one end of the rotating shaft is connected with a rotating shaft rotation driving device mounted on the stern control box, a plurality of vanes are arranged between the V-shaped rotary plate and the ship bilge strake and rotationally connected to vane limiting holes in the bow support box and the stern control box through vane supporting shafts mounted on the vanes respectively, and the inner cross beams can rotate around the rotating shaft under the drive of the driving device and are attached to the vanes. With the adoption of the device, the bilge keel can be folded in a limited navigation channel or small storm waves, and damage caused by grounding, collision and the like is prevented.

Owner:北京传奇优声文化传媒有限公司

Roll suppression device for offshore structure

InactiveUS8347803B2Improve efficiencyImprove stabilityVessel movement reduction by foilsVessel safetyMarine engineeringKeel

The present disclosure relates to a roll-suppression device for an offshore structure. The device includes a damping plate separated downward from a hull to be placed below a bottom of the offshore structure by a connection unit, so that the width of the damping plate may be effectively enlarged without occurrence of collision during shuttle docking or ship-to-ship operation. Accordingly, the device may maximize roll-suppression, as compared with a bilge-keel or a step, and a detachable design of the device facilitates ship construction or shore operation inside a drydock.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Control method of frog mouth type bilge keel

InactiveCN105539759ADoes not affect speedIncrease dampingBilge keelsVessel movement reduction by foilsLower limitShip stability

The invention relates to a control method of a frog mouth type bilge keel. A main structure of the frog mouth type bilge keel comprises a fixed clamshell structure (2) and a rotary clamshell structure (1). The rotary clamshell structure (1) is connected with the fixed clamshell structure (2) through a rotary shaft system. The control method of the frog mouth type bilge keel includes the steps that when a ship sails, the rolling angle, the angular speed and the angular accelerated speed of the ship are monitored, ship draught information is obtained, and the ship stability change is checked; if any index of the three parameters including the rolling angle, the angular speed and the angular accelerated speed continuously exceeds the upper limit of a corresponding safety threshold value within a set time, a motor is used for driving the rotary shaft system to unfold the rotary clamshell structure of the bilge keel; and if the three parameters including the rolling angle, the angular speed and the angular accelerated speed are continuously lower than the lower limit of the corresponding safety threshold value within the set time, the motor is used for driving the rotary shaft system to fold the rotary clamshell structure of the bilge keel. By the adoption of the control method of the frog mouth type bilge keel, the bilge keel can be intelligently controlled to be unfolded and folded; and the rolling damping of the ship can be increased, rolling of the ship is effectively reduced, and rolling stability is enhanced.

Owner:TIANJIN UNIV

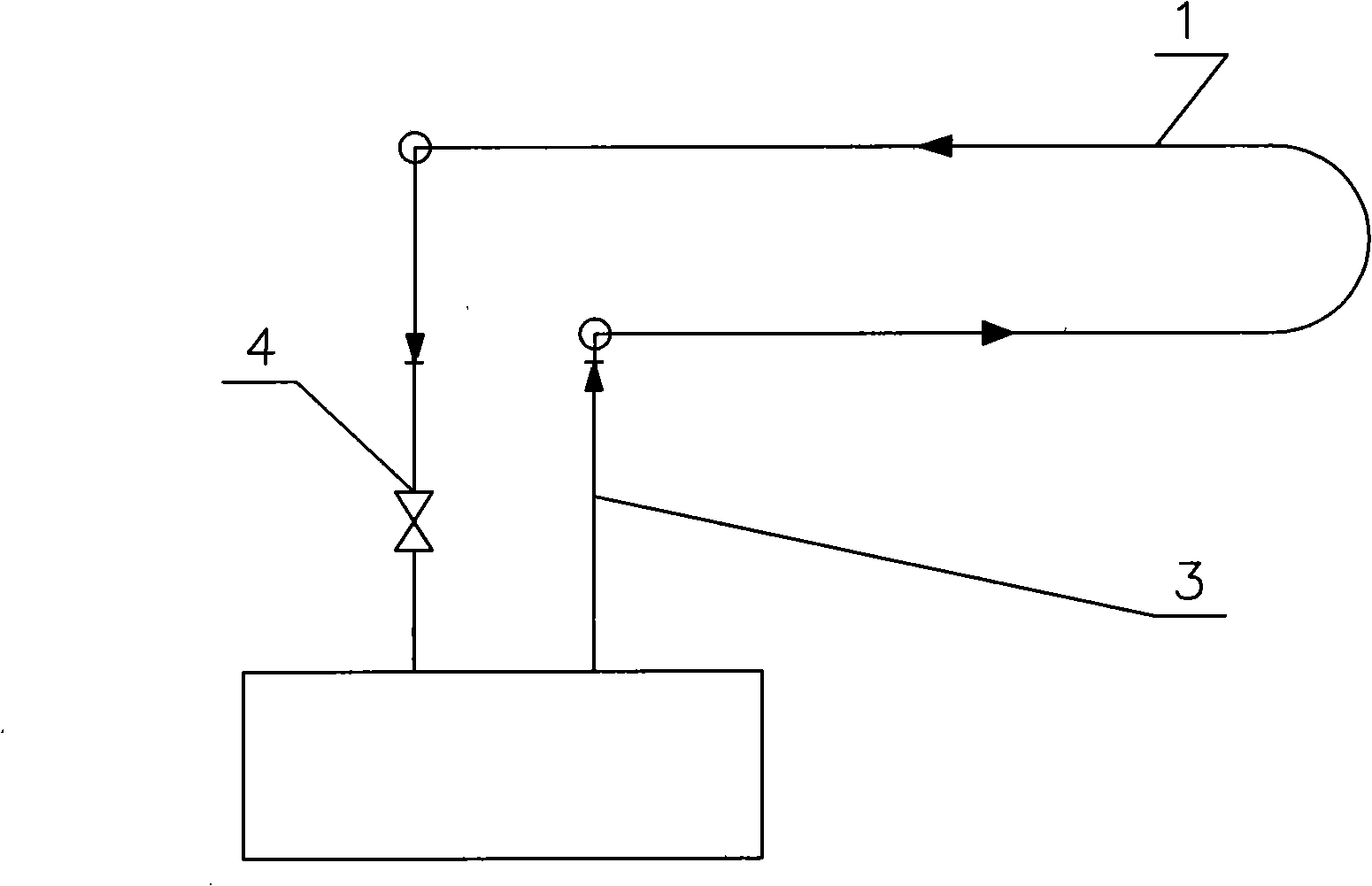

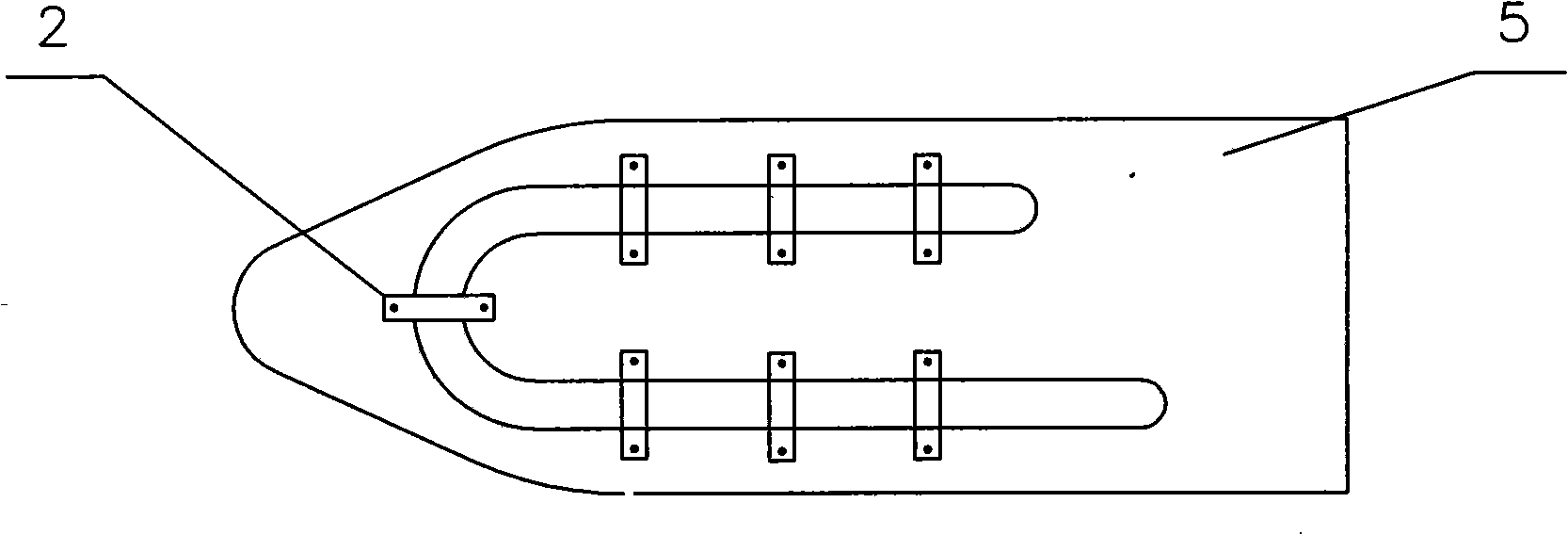

Cooling method and apparatus for cooling circulating water of glass fibre reinforced plastic ship internal-combustion engine

ActiveCN101298282AReduce resistanceDoes not affect speedAuxillariesPropulsion power plantsKeelCooling effect

The invention discloses a cooling method and a cooling device for the recycled cooling water in the internal-combustion engine of the glass reinforced plastic boat, the device is characterized in that a cooling coil is made by lofting firstly according to the linetype of the shell plate at both sides of the bilge keel and secondly bending into the cooling coil which is in line with the linetype of the shell plate, then the coil is directly arranged at the outer side of the shell plate at both sides of the bilge keel through coil clamping code; one end of the cooling coil is connected with an outlet pipe of the drive device and another end is connected with a fresh water pump of the drive device to form a closed type cooling system, the heat of the fresh water in a tubular type outboard cooler is carried away by the seawater. The cooling method and the cooling device of the invention have the advantages of easy production, convenient assembly, energy conservation, good cooling effect, etc.; meanwhile, the speed of the boat is not affected.

Owner:WEIHAI ZHONGFU XIGANG SHIP

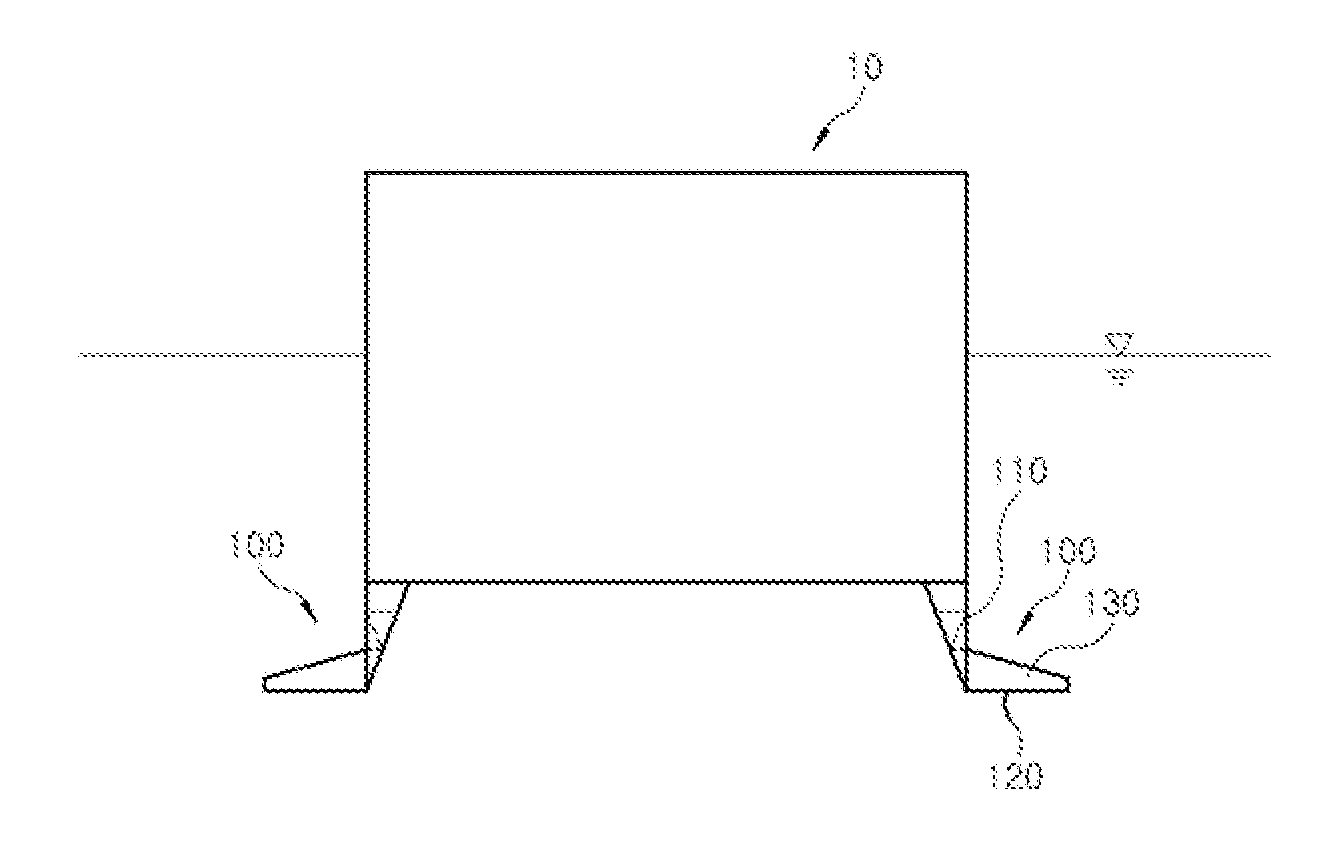

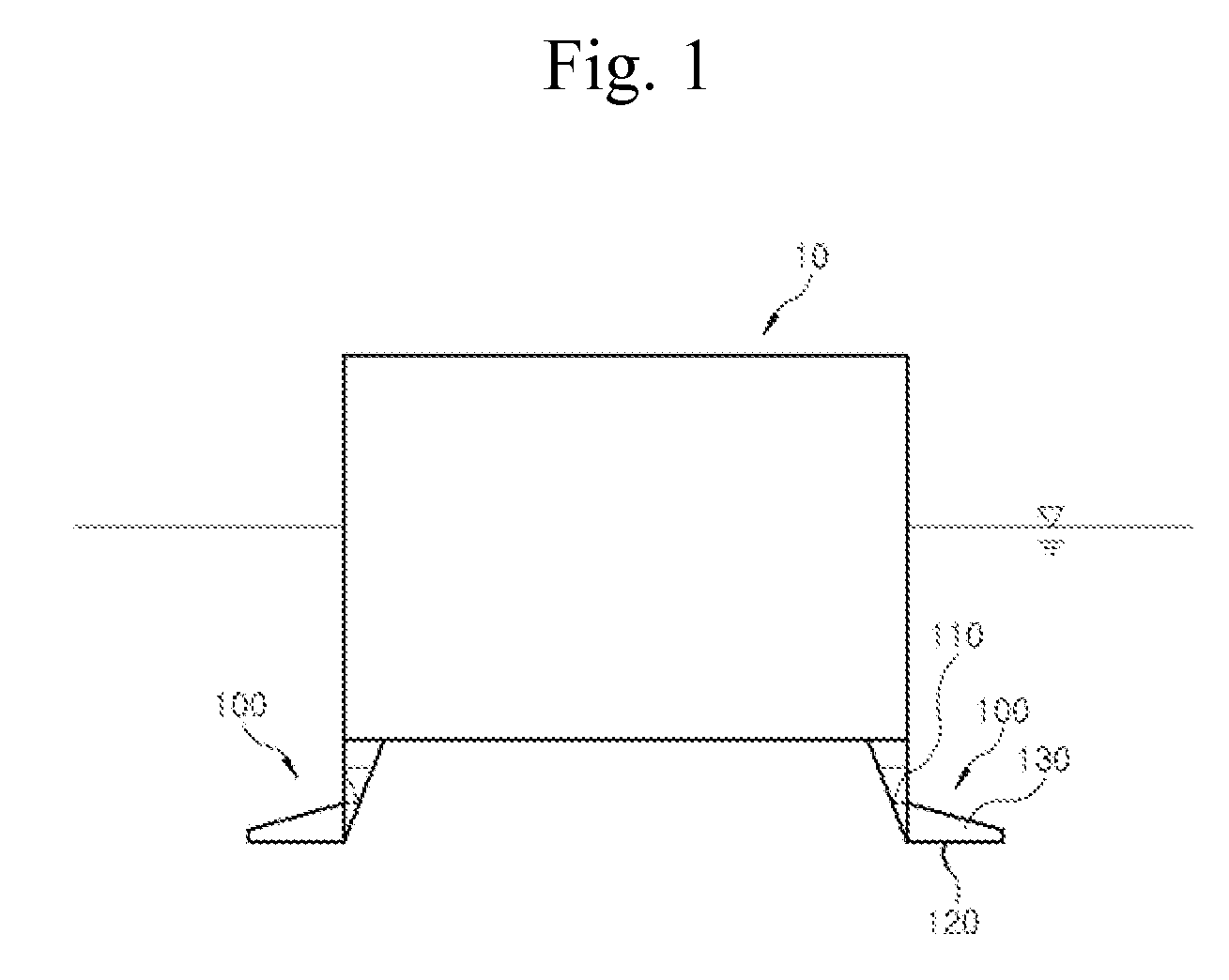

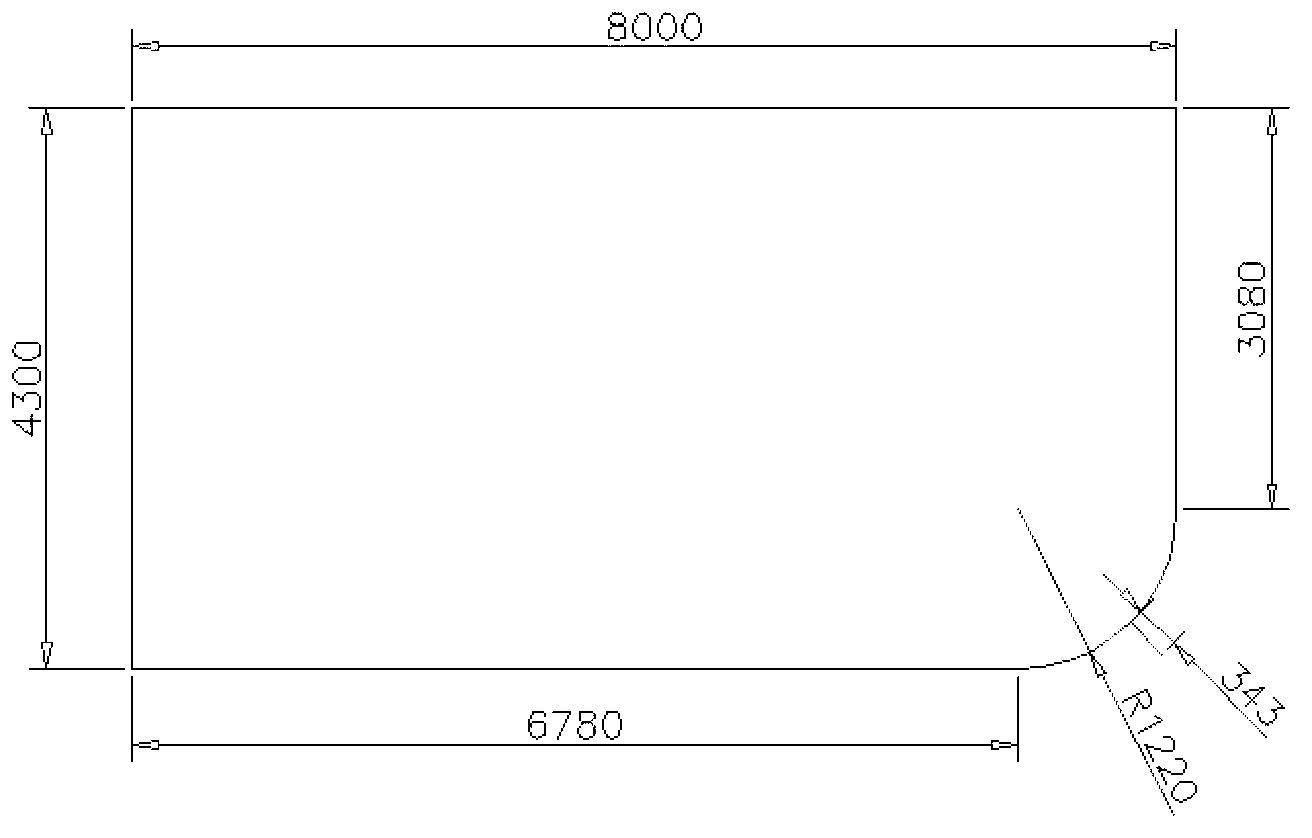

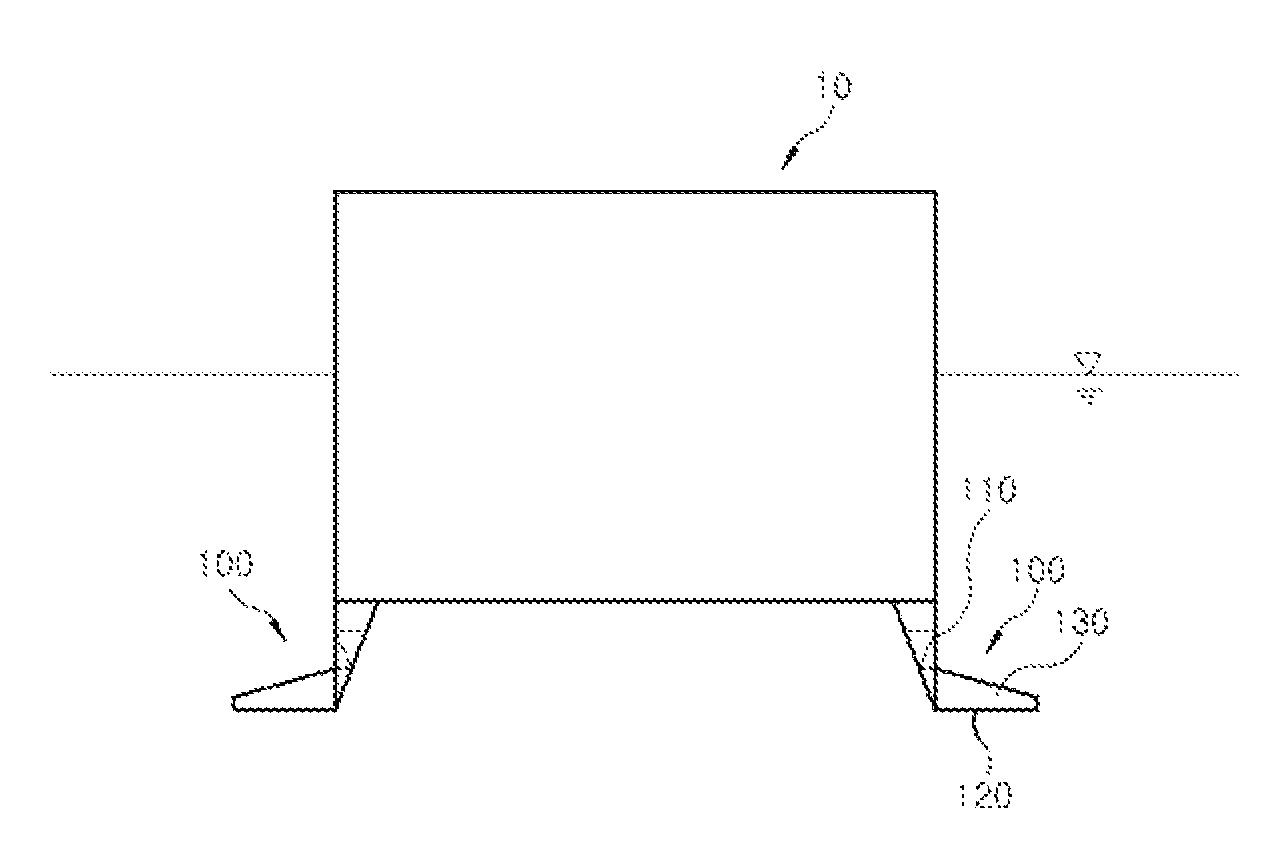

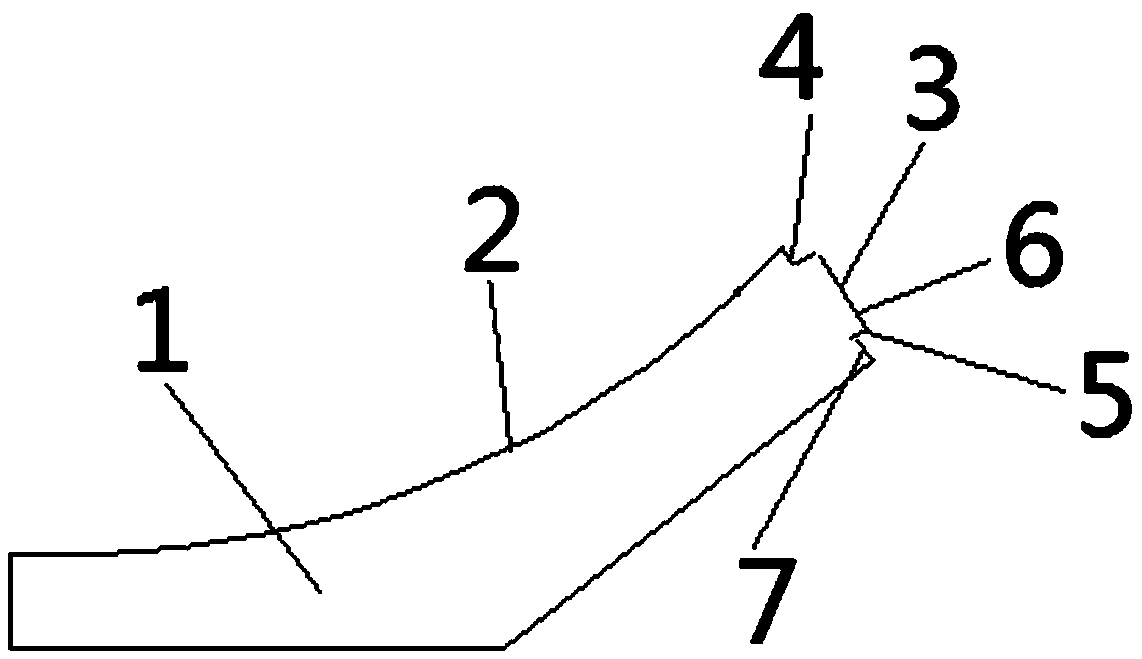

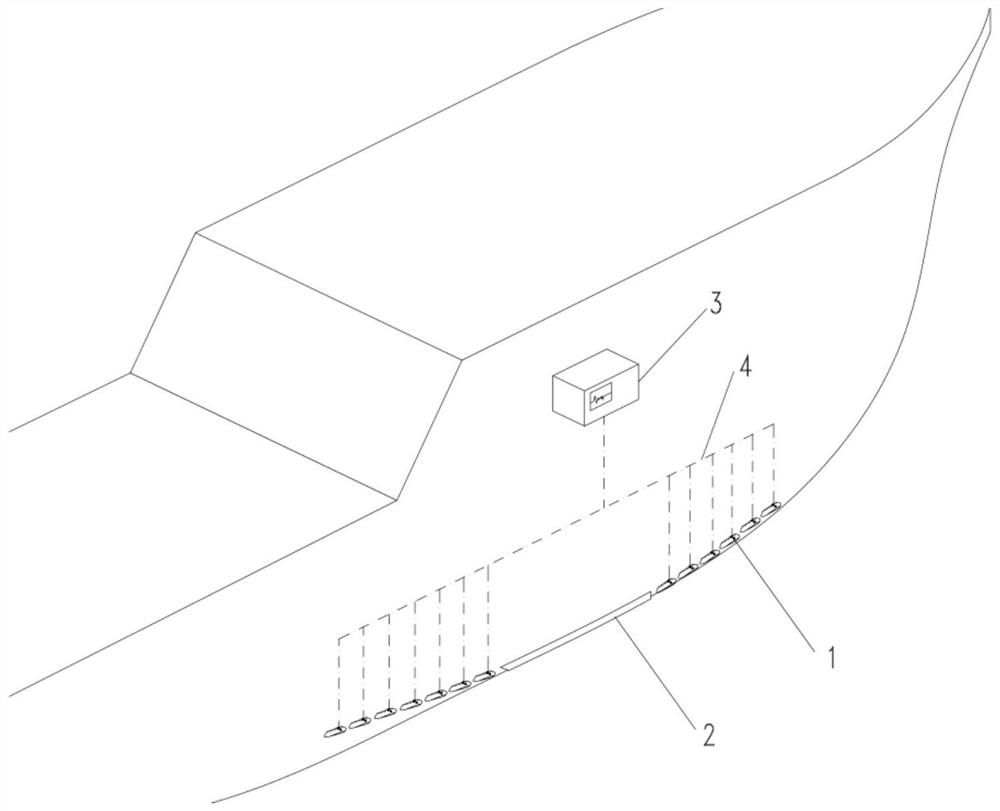

Positioning installation mold

ActiveCN108820129AImprove installation efficiencyImprove positioning and installation accuracyWatercraft hull designVessel designingBilgeKeel

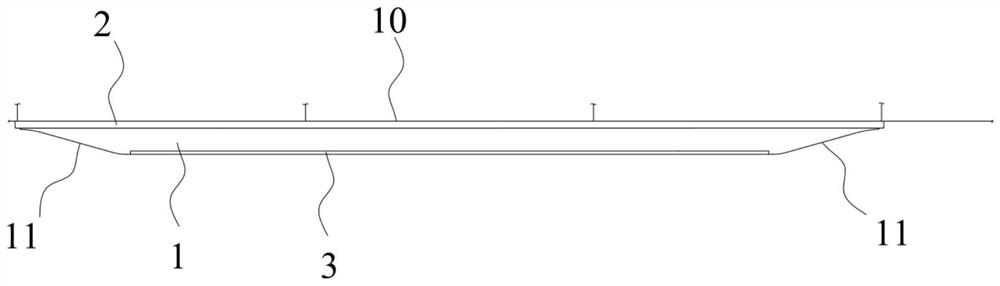

The invention provides a positioning installation mold for positioning and installing a bilge keel in a bilge area of a hull; the positioning installation mold comprises a curved plate, a positioningportion and two support plates, wherein the two support plates are respectively connected to an arc segment at both ends of the curved plate, the positioning portion is connected between the two support plates, the positioning portion is connected with the curved plate; the arc segment of the curved plate matches the outer surface shape of the bilge area and the curved plate fits over the bilge area, the plane in which the positioning portion lies passes through the curvature center of the outer surface of the bilge area, and the positioning portion is aligned with the bilge keel. The positioning installation mold improves the installation efficiency of the bilge keel, improves the positioning installation precision of the bilge keel, reduces the installation error and deformation, thus, the work of repairing and closing the bilge keel caused by the second opening of the dock is avoided, the construction difficulty is reduced, and the ship performance is improved. In addition, shipbuilding costs and labor hours are reduced.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

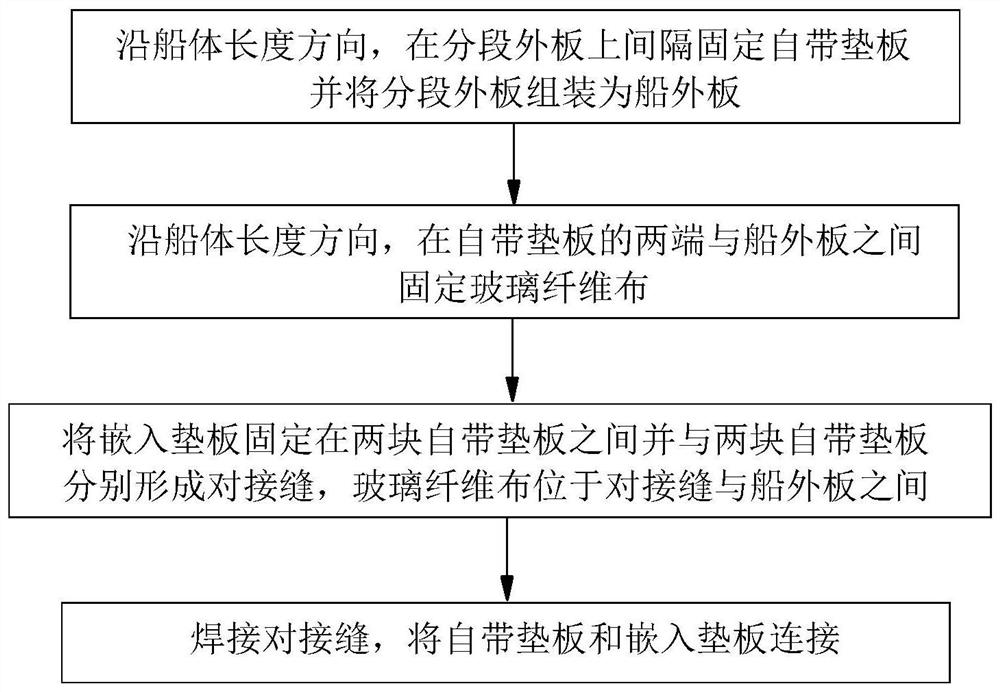

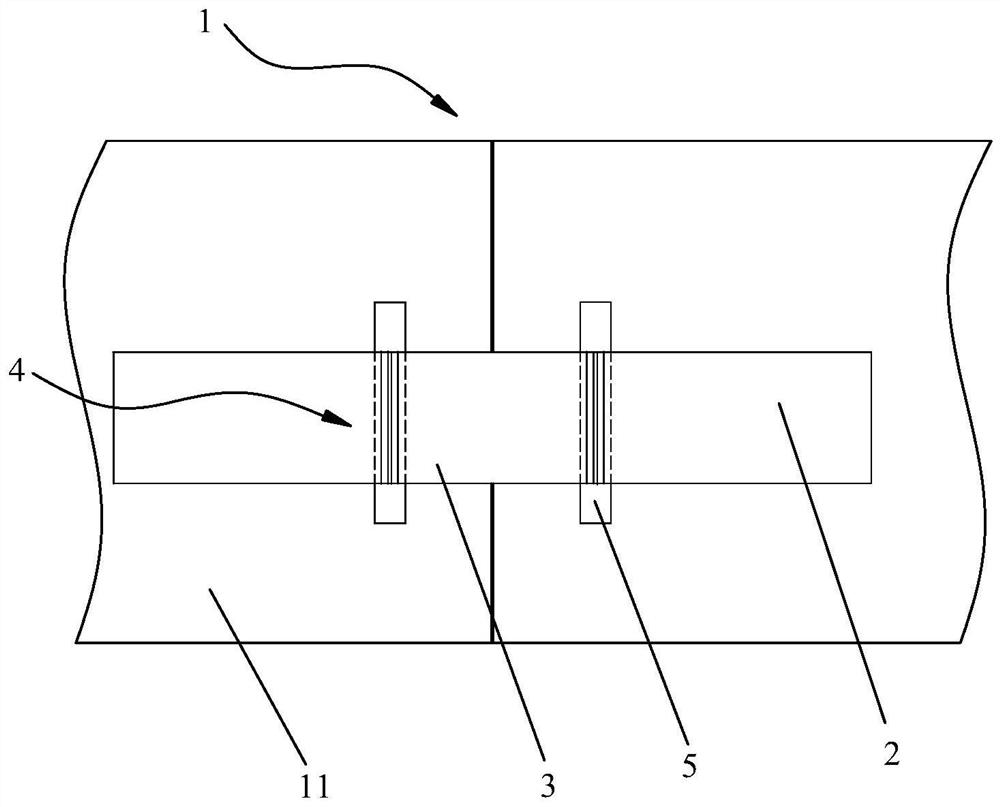

Hull bilge keel base plate mounting method

InactiveCN111619758AEasy to operateGuaranteed continuityVessel movement reduction by foilsMovement controllersGlass fiberButt joint

The invention relates to the technical field of shipbuilding, and discloses a hull bilge keel base plate mounting method. The ship bilge keel base plate mounting method comprises the steps of fixing built-in base plates to segmented outer plates at intervals in the length direction of a hull, and assembling the segmented outer plates into a ship outer plate; fixing glass fiber cloth between the two ends of the built-in base plate and the ship outer plate in the length direction of the hull; fixing an embedded base plate between the two built-in base plates, and forming a butt joint seam by theembedded base plate and the two built-in base plates, wherein the glass fiber cloth is located between the butt joint seam and the ship outer plate; and welding the butt joint seam so as to enable the built-in base plate and the embedded base plate to be connected. According to the hull bilge keel base plate mounting method, the base plate connection reliability is high, and the ship outer plateis not prone to damage.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Bilge keel structure of ship

InactiveCN113022807AExtended service lifeReduce workloadVessel movement reduction by foilsMovement controllersKeelBilge

The invention discloses a bilge keel structure of a ship, and relates to the technical field of ship design. The bilge keel structure of the ship is symmetrically arranged on bilge parts on the two sides of the ship in the width direction and connected with an outer plate of the ship, the bilge keel structure comprises a plurality of bilge keel bodies and a plurality of cushion blocks, the multiple bilge keel bodies are evenly arranged at intervals in the hull streamline direction of the ship, and all the bilge keel bodies extend in the hull streamline direction of the ship. The multiple bilge keel bodies are all connected with the outer plate. The multiple cushion blocks are evenly arranged at intervals in the streamline direction of a ship body, the multiple cushion blocks correspond to the multiple bilge keel bodies one to one, the cushion blocks are arranged between the bilge keel bodies and the outer plate, and the two sides of the cushion blocks are connected with the bilge keel bodies and the outer plate correspondingly. The multiple bilge keel bodies are evenly arranged in the streamline direction of the ship body at intervals, the workload of continuous welding can be reduced, and the mounting and assembling preassembling rate is increased. Meanwhile, when one bilge keel body falls off, other bilge keel bodies cannot be influenced, and therefore the damage influence range cannot be enlarged.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Ship body and deep V-shaped bevel half-small waterplane area catamaran

InactiveCN113734349AImprove seakeepingImprove airworthinessWatercraft hull designVessel movement reduction by foilsKeelWind wave

The invention discloses a hull and a deep V-shaped bevel half-small waterplane area catamaran, and belongs to the technical field of ships. The ship body comprises a double-piece body, a first anti-rolling bilge keel and a second anti-rolling bilge keel, the longitudinal section of the bottom of the first submerged body and the longitudinal section of the bottom of the second submerged body are of a V-shaped structure, and the first anti-rolling bilge keel is arranged on the side, away from the second submerged body, of the first submerged body in a protruding mode. The first anti-rolling bilge keel extends in the length direction of the first submerged body; the second anti-rolling bilge keel is arranged on the side, away from the first submerged body, of the second submerged body in a protruding mode, and the second anti-rolling bilge keel extends in the length direction of the second submerged body. The first anti-rolling bilge keel and the second anti-rolling bilge keel are located at the same height and are in bilateral symmetry relative to the hull. And the comprehensive counter-acting force of the first anti-rolling bilge keel and the second anti-rolling bilge keel can force the ship body to be straightened and erected, the wind wave resistance is high, and the seakeeping performance, the seaworthiness and the riding comfort of the ship are improved.

Owner:AFAI SOUTHERN SHIPYARDPANYU GUANGZHOU LTD

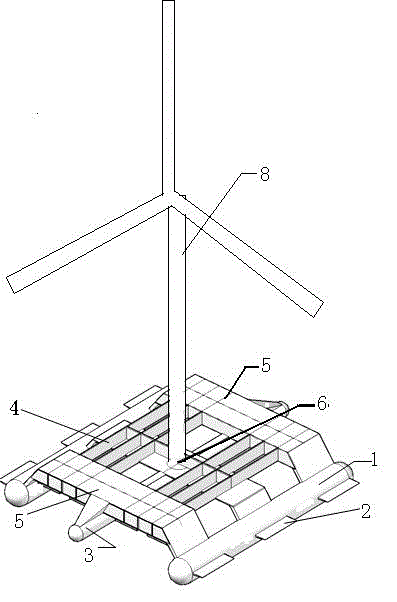

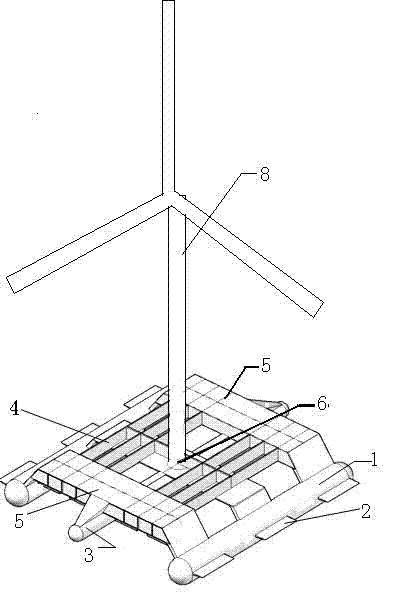

Floating integrated energy platform

The invention discloses a floating type comprehensive energy platform. The floating type comprehensive energy platform comprises a platform body, and is characterized in that the whole platform body is provided with a symmetric structure of a small water plane catamaran; large floating barrels are arranged on two sides of the platform body; a plurality of bilge keels for preventing excessive rolling are arranged on the large floating barrels; small floating barrels parallel to the large floating barrels are arranged at the bottom of the middle part of the platform body; and a plurality of longitudinal girders capable of improving the total longitudinal strength are symmetrically arranged on the platform body. With the adoption of the floating type comprehensive energy platform disclosed by the invention, the requirement of ocean platform specification on stability in the inclination angle is met, a fan can be prevented from being overturned and can be kept in normal running; and little wave response is generated, therefore, the safety in operation is ensured.

Owner:傅嵩

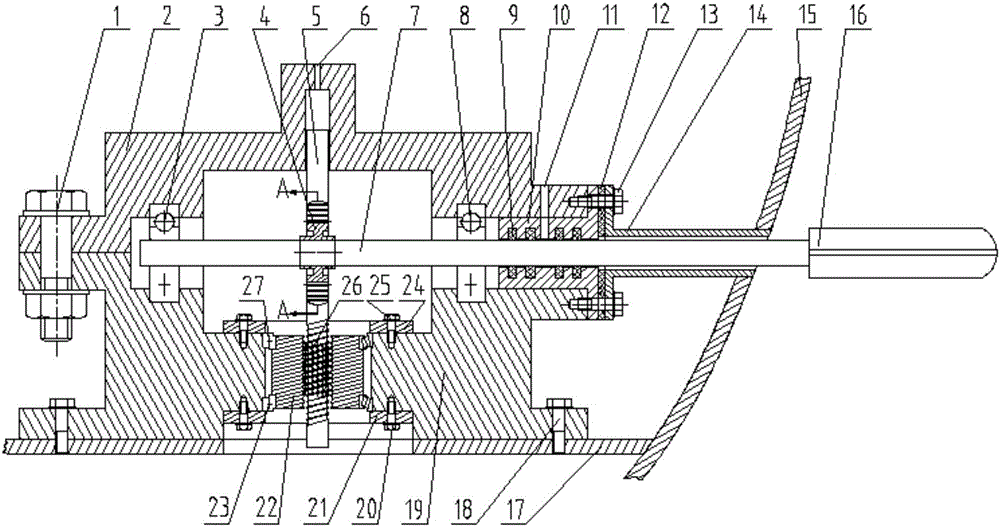

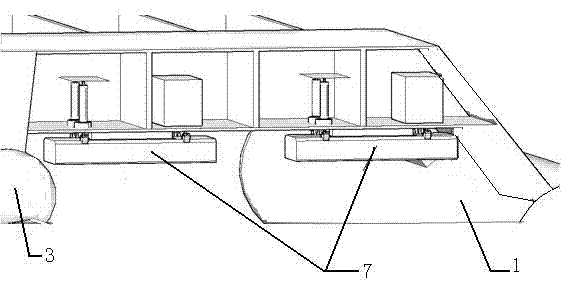

Ship fin stabilizer with semi-active control type inertial structure

ActiveCN105775064AIncrease inertiaCompact installation spaceVessel movement reduction by foilsSemi activeRubber ring

The invention discloses a ship fin stabilizer with a semi-active control type inertial structure. The ship fin stabilizer comprises an upper shell, a lower shell, a fin rod, a ball screw type inerter assembly, a gear and rack transmission mechanism and a sealing structure. The upper shell and the lower shell are connected. The lower shell and a hull board are connected. The ball screw type inerter assembly comprises a penetrating screw, a bearing lower limiting ring, a flywheel, a bearing upper limiting ring and a ball. The sealing structure comprises a rubber ring A, a sealing shell, a rubber ring B and a welding sleeve. By the adoption of the ship fin stabilizer, the ball screw type inerter assembly is designed into an inner control structure of the semi-active fin stabilizer; compared with an active fin stabilizer structure, the structure is greatly simplified; compared with a bilge keel, the ship fin stabilizer has the beneficial effects of being optimized in stabilization effect, economical, environment-friendly, capable of saving energy and high in engineering application value.

Owner:JIANGSU UNIV OF SCI & TECH

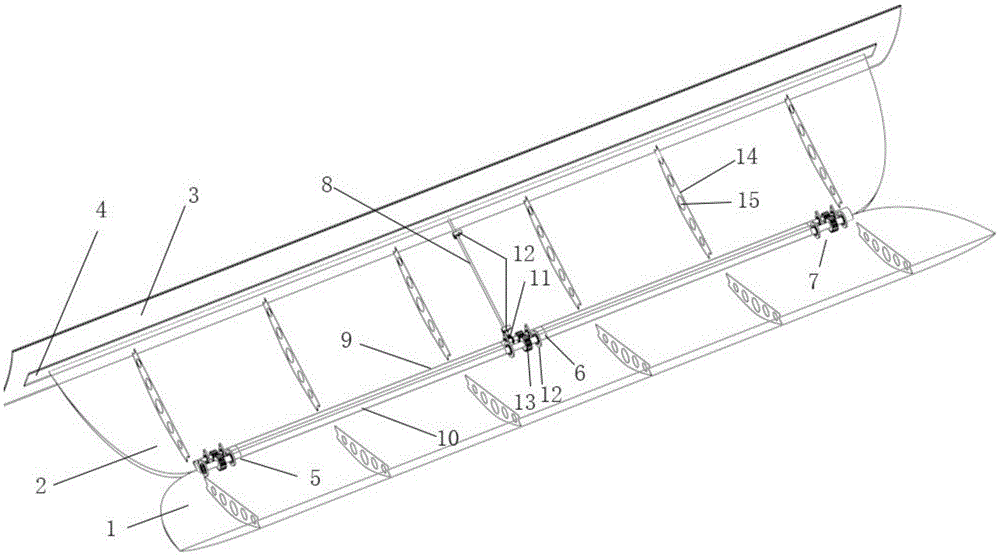

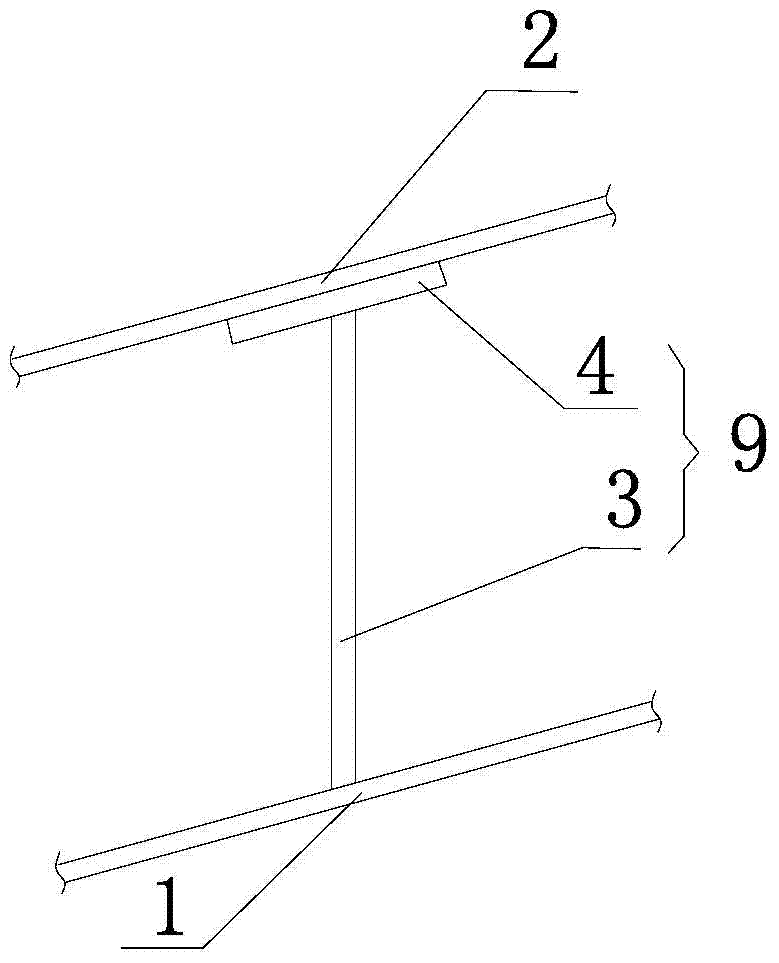

A double-plate bilge keel and its installation method

ActiveCN105416523BSimple structureEasy to manufactureVessel movement reduction by foilsMovement controllersKeelEngineering

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

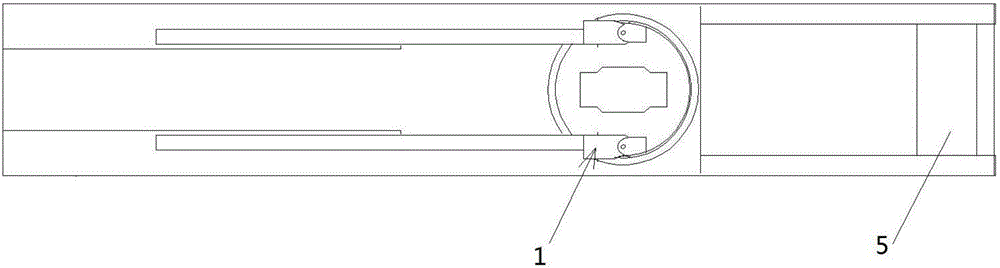

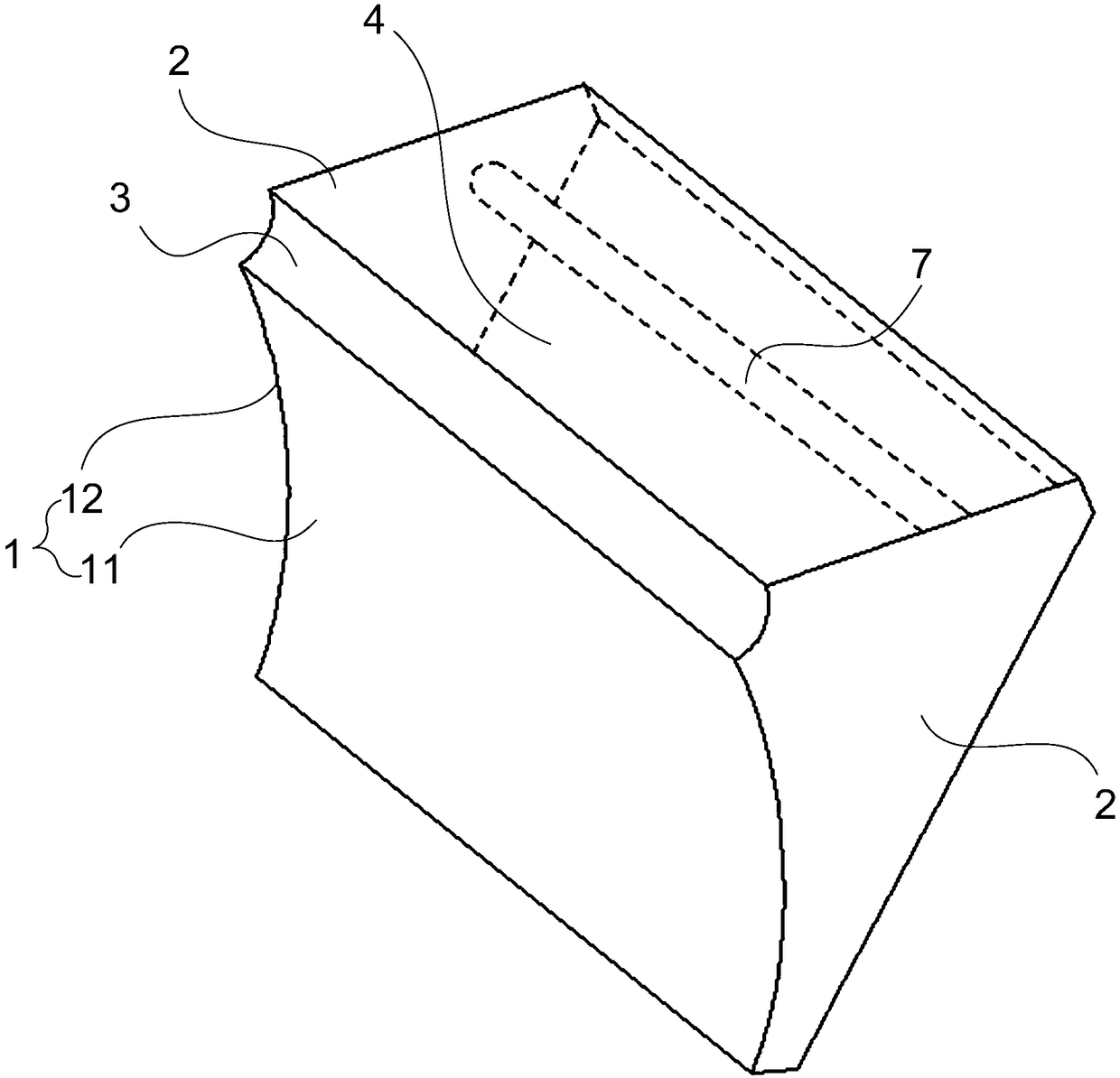

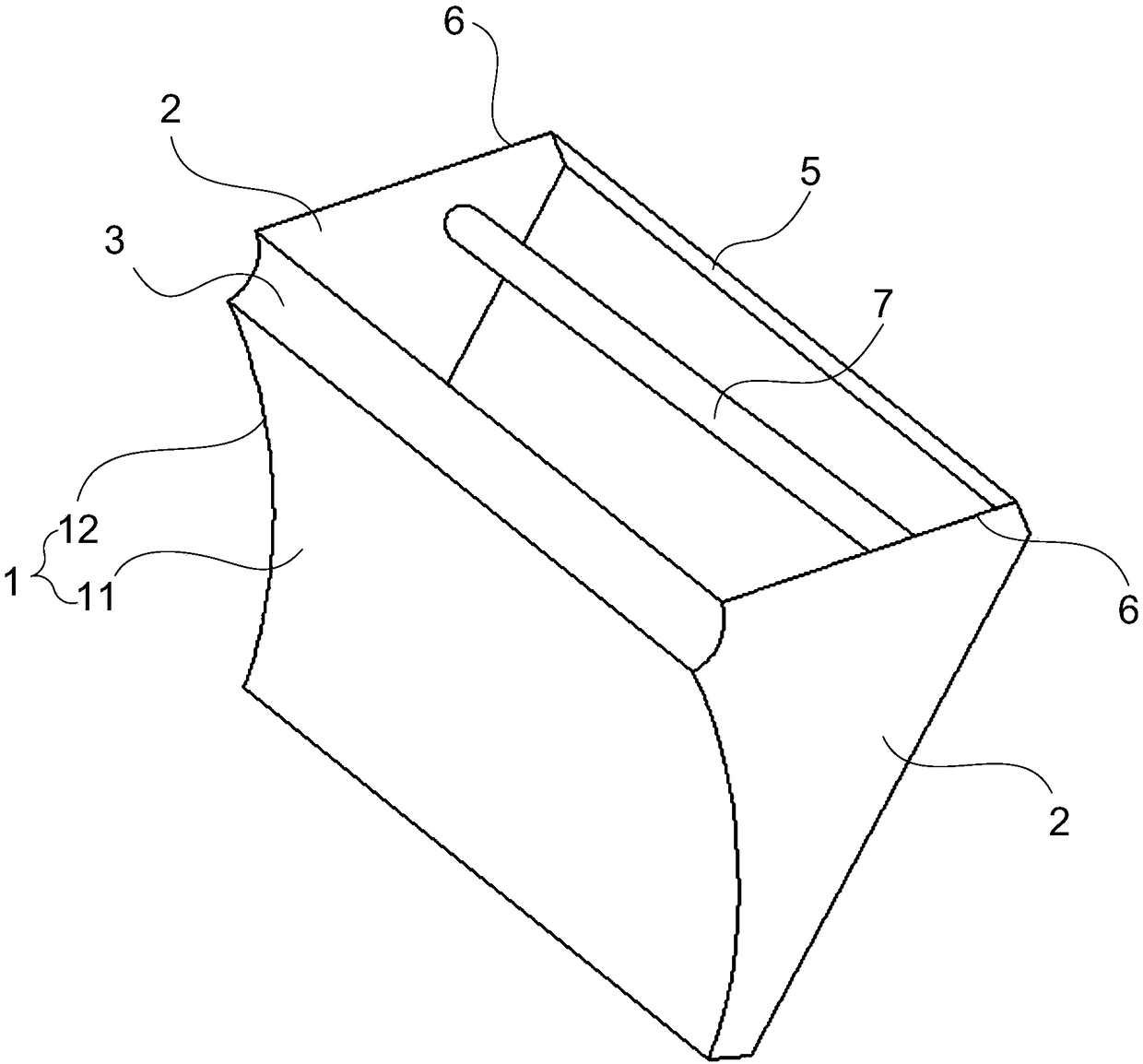

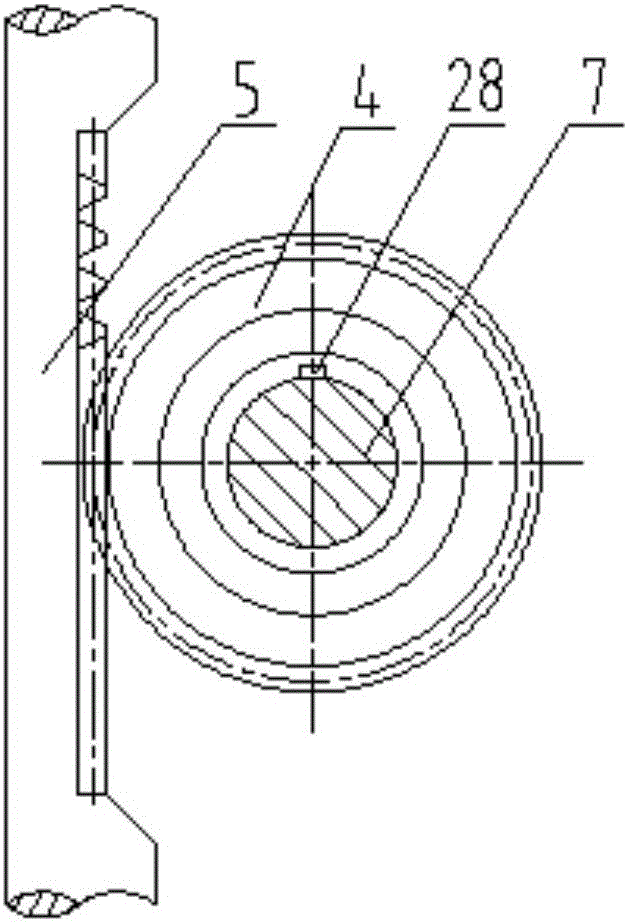

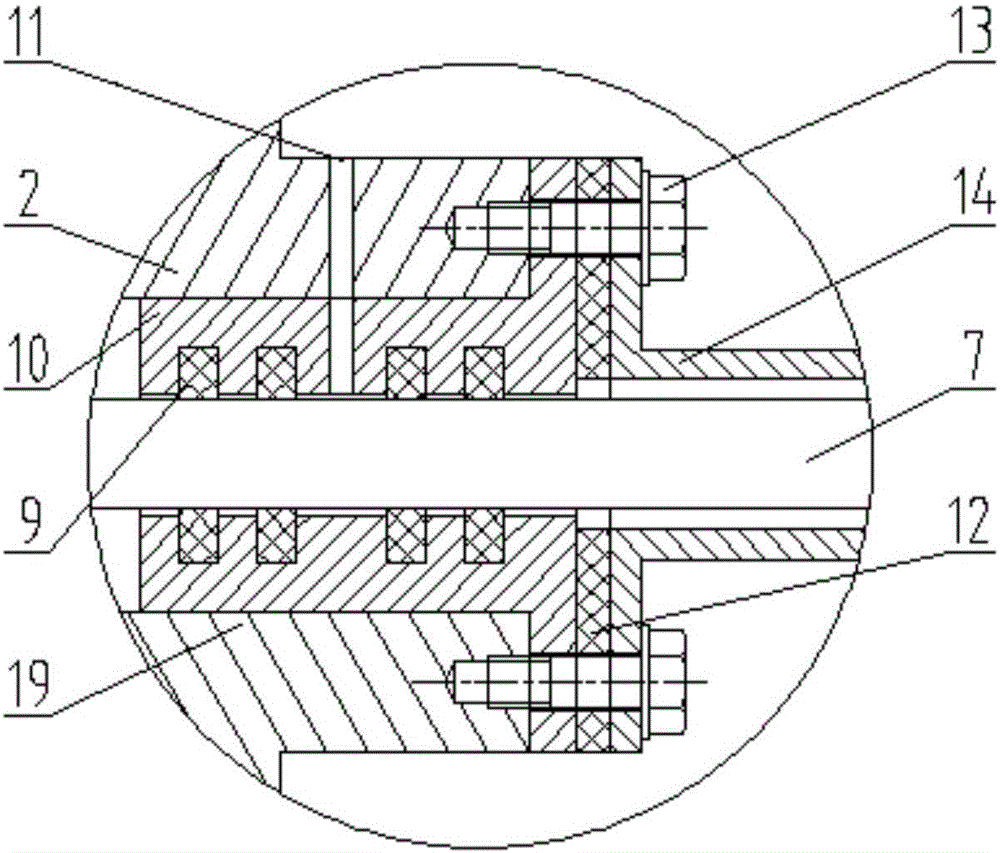

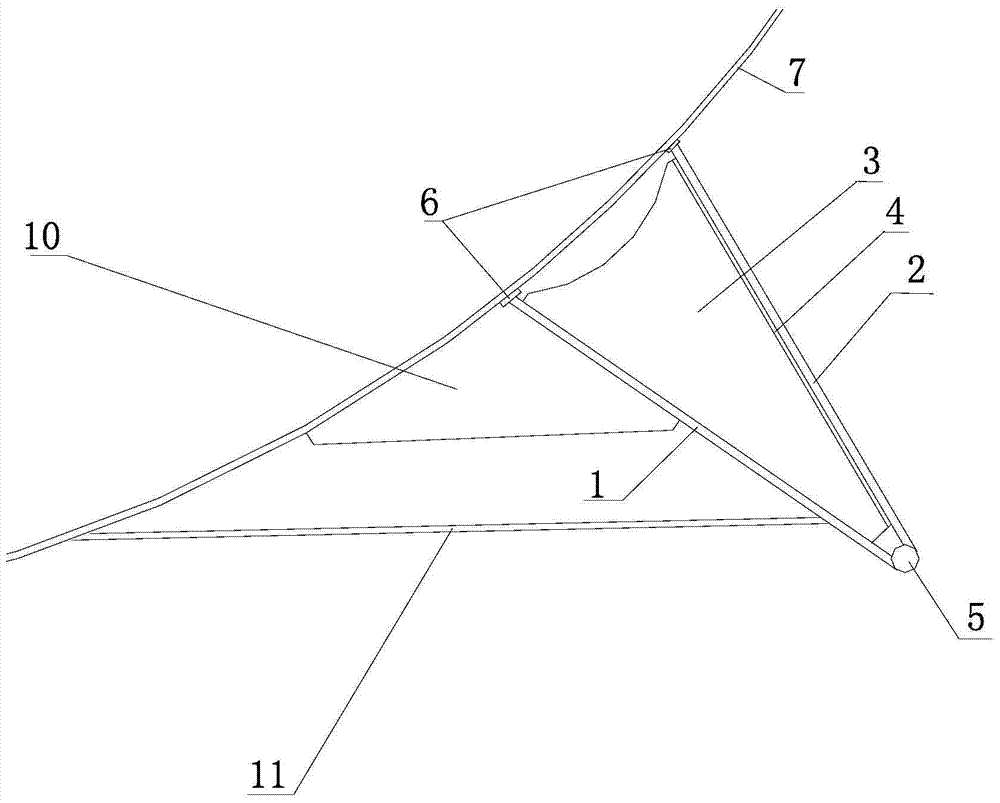

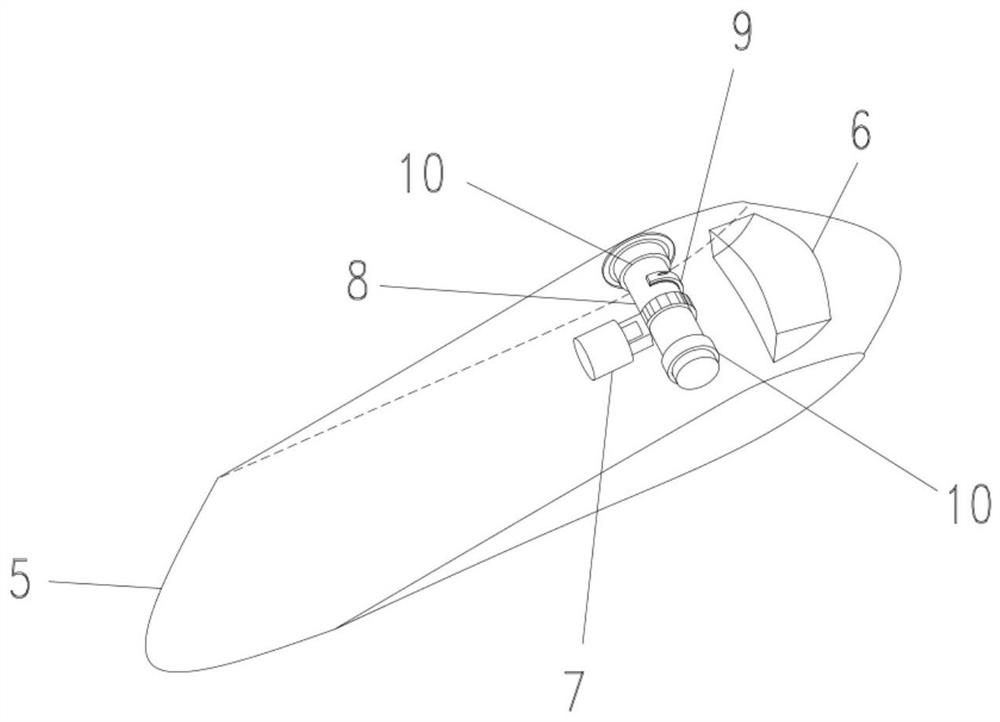

Ship bilge keel mounting bed-jig template and mounting method thereof

InactiveCN109552573AHigh positioning accuracyReduce workloadDry-dockingSlipwaysKeelMarine engineering

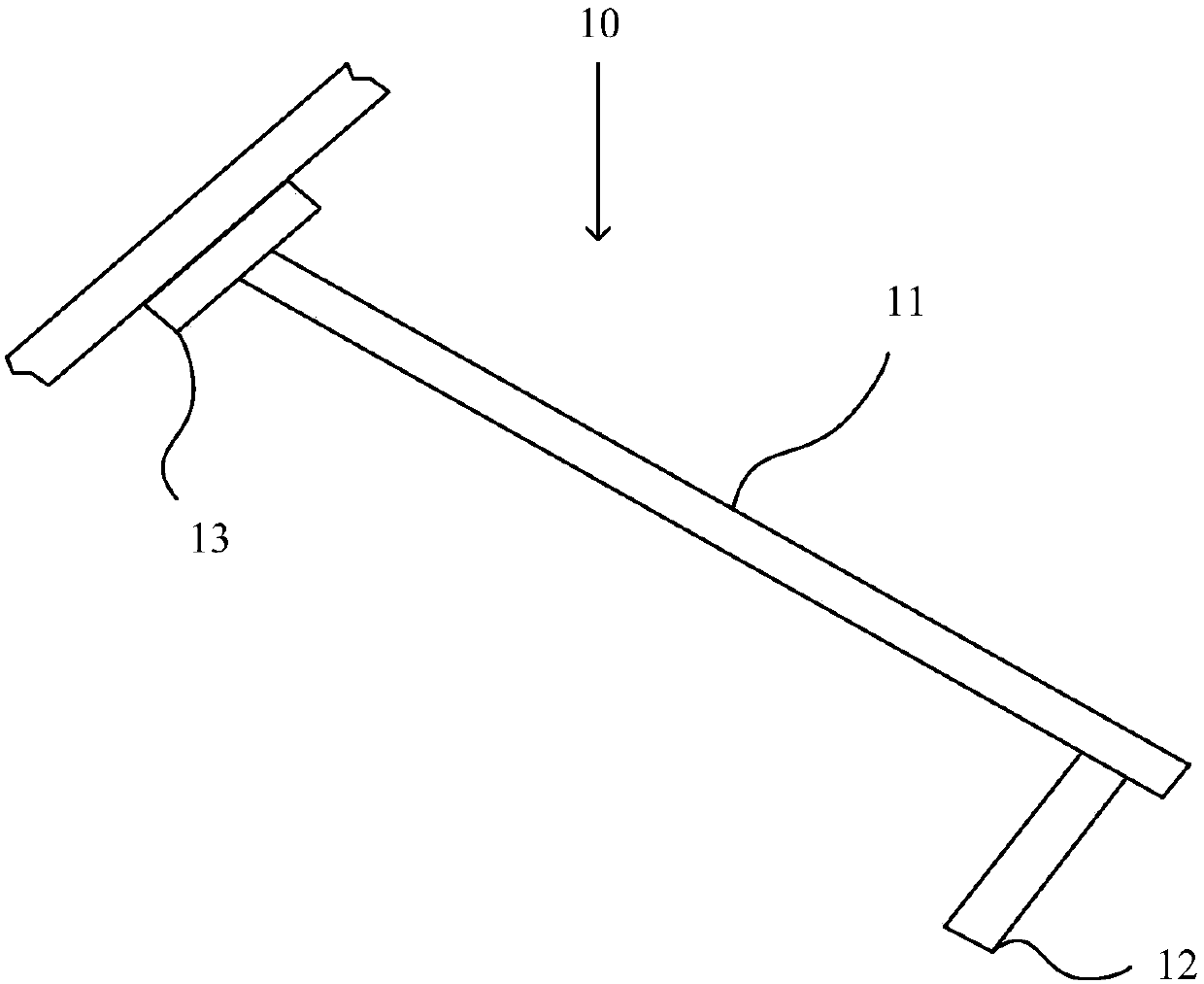

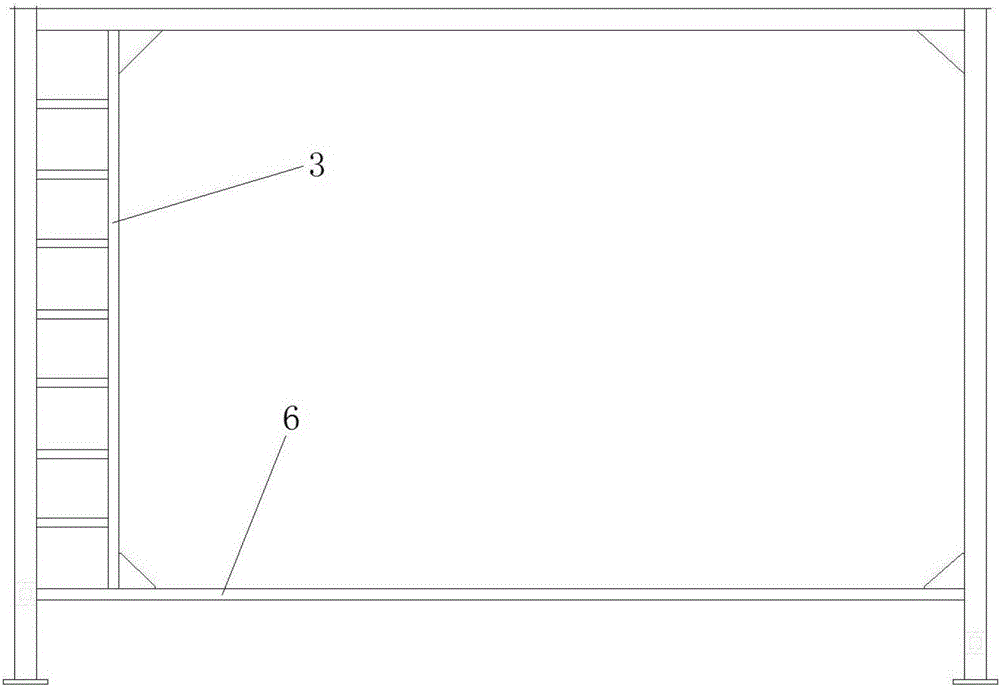

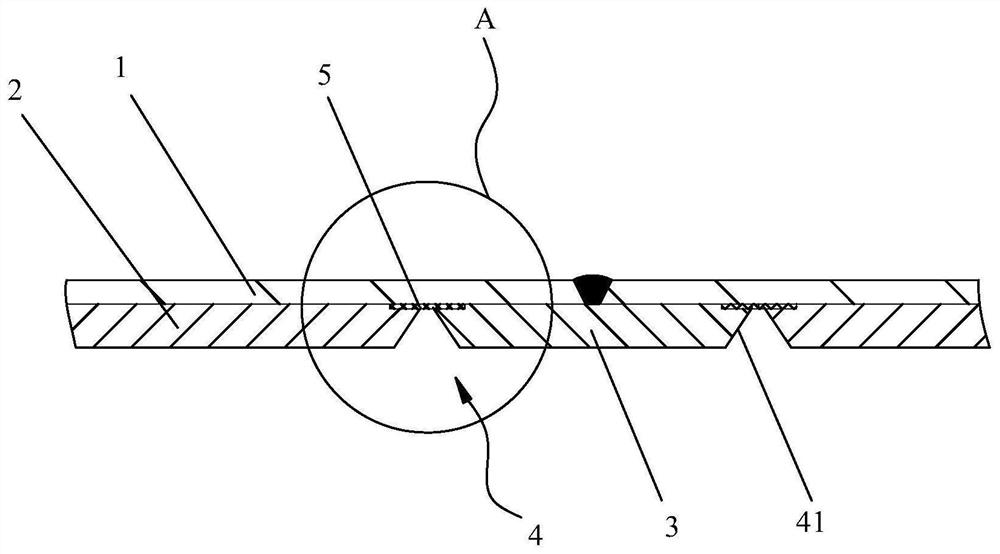

The invention provides a ship bilge keel mounting bed-jig template applied to the technical field of ship bilge keel mounting auxiliary tools. The invention further relates to a ship bilge keel mounting method. One end of a template piece (1) of the ship bilge keel mounting bed-jig template is a locating arc part (2); one side of the template piece (1) is a bilge keel locating part (3); a concavepart (4) is arranged at the combined part of the bilge keel locating part (3) and the locating arc part (2); a step part (5) is also arranged on the bilge keel locating part (3); and the step part (5)divides the bilge keel locating part (3) into a first locating surface (6) and a second locating surface (7). According to the ship bilge keel mounting bed-jig template and the ship bilge keel mounting method, the structure is simple, the ship bilge keel and a ship-hull plate can be conveniently and accurately located and mounted, and it is important that the workload of the ship bilge keel mounting process is effectively reduced by changing the mounting time section of the ship bilge keel.

Owner:WUHU SHIPYARD CO LTD

Novel intelligent resistance-reducing bilge keel

InactiveCN112158307AReduce resistanceKeep StabilizerWatercraft hull designVessel movement reduction by foilsBilgeKeel

The invention relates to a novel intelligent resistance reduction bilge keel which comprises a conventional bilge keel part, a discrete bilge keel part and an intelligent control module. The discretebilge keel part is arranged at the part with different flow lines under various working conditions of a bilge and comprises a plurality of leaf-shaped rotatable bilge keels, and the leaf-shaped rotatable bilge keels are all connected with the intelligent control module. Compared with the prior art, the part, inconsistent with the streamline, of a conventional bilge keel due to various navigationalspeeds, various drafts and other working conditions is removed and replaced with the multiple discrete leaf-shaped bilge keel structures capable of intelligently adjusting the angle, and the discreteleaf-shaped bilge keel structures intelligently adjust the angle along the streamline during sailing; and therefore, the resistance is reduced, and the device has important use value for ships with relatively short parallel midbodies and complex and variable navigation working conditions.

Owner:SHANGHAI JIAO TONG UNIV

Floating type comprehensive energy platform

The invention discloses a floating type comprehensive energy platform. The floating type comprehensive energy platform comprises a platform body, and is characterized in that the whole platform body is provided with a symmetric structure of a small water plane catamaran; large floating barrels are arranged on two sides of the platform body; a plurality of bilge keels for preventing excessive rolling are arranged on the large floating barrels; small floating barrels parallel to the large floating barrels are arranged at the bottom of the middle part of the platform body; and a plurality of longitudinal girders capable of improving the total longitudinal strength are symmetrically arranged on the platform body. With the adoption of the floating type comprehensive energy platform disclosed by the invention, the requirement of ocean platform specification on stability in the inclination angle is met, a fan can be prevented from being overturned and can be kept in normal running; and little wave response is generated, therefore, the safety in operation is ensured.

Owner:傅嵩

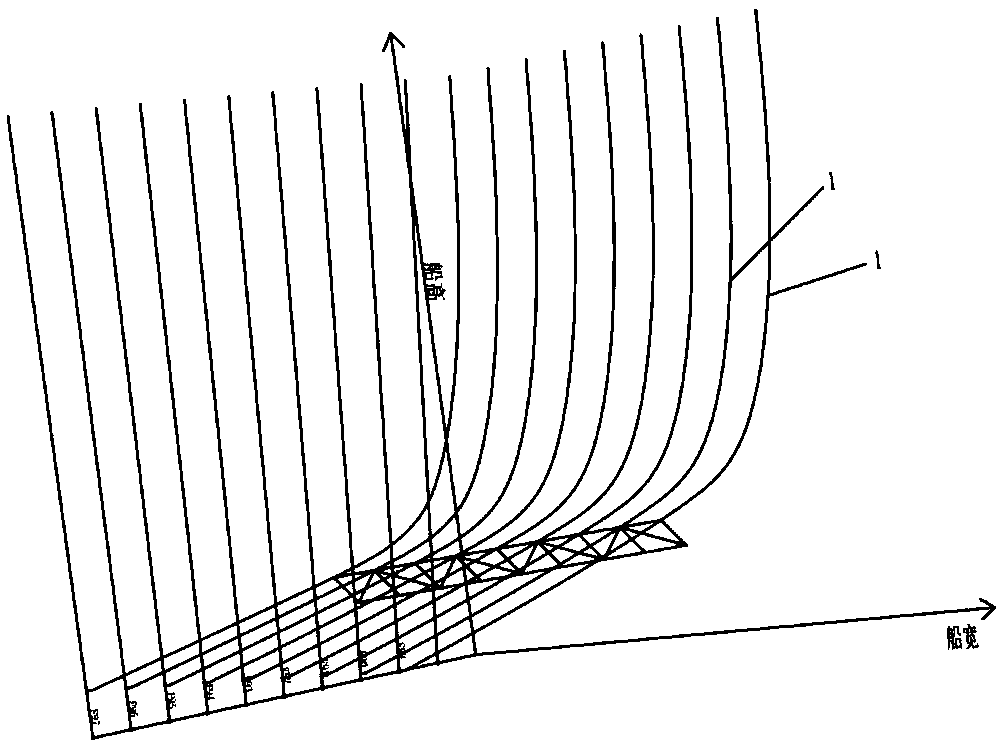

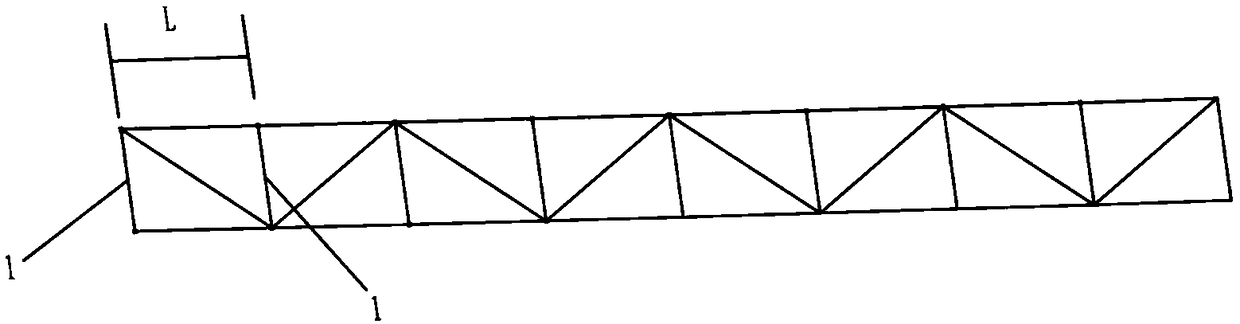

Bilge keel unfolding method

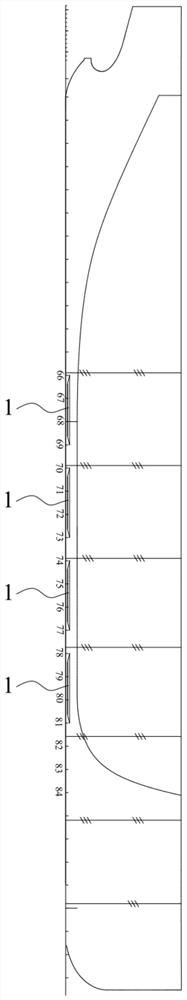

The invention relates to the technical field of hull construction, A method for unfolding a bilge keel is disclosed, the bilge keel is divided along the hull length according to the rib spacing by three-dimensional modeling method, converting the bilge keel between two adjacent ribs into a quadrilateral bilge keel area, The diagonal line connecting the quadrilateral turns the bilge keel area intotwo triangular areas, and measures the side length of the triangle on the model diagram, which can reflect the line shape of the bilge keel intuitively and clearly through the method of constructing the model diagram. At the same time, the development diagram obtained by directly measuring the real length on the model diagram is more accurate and efficient.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

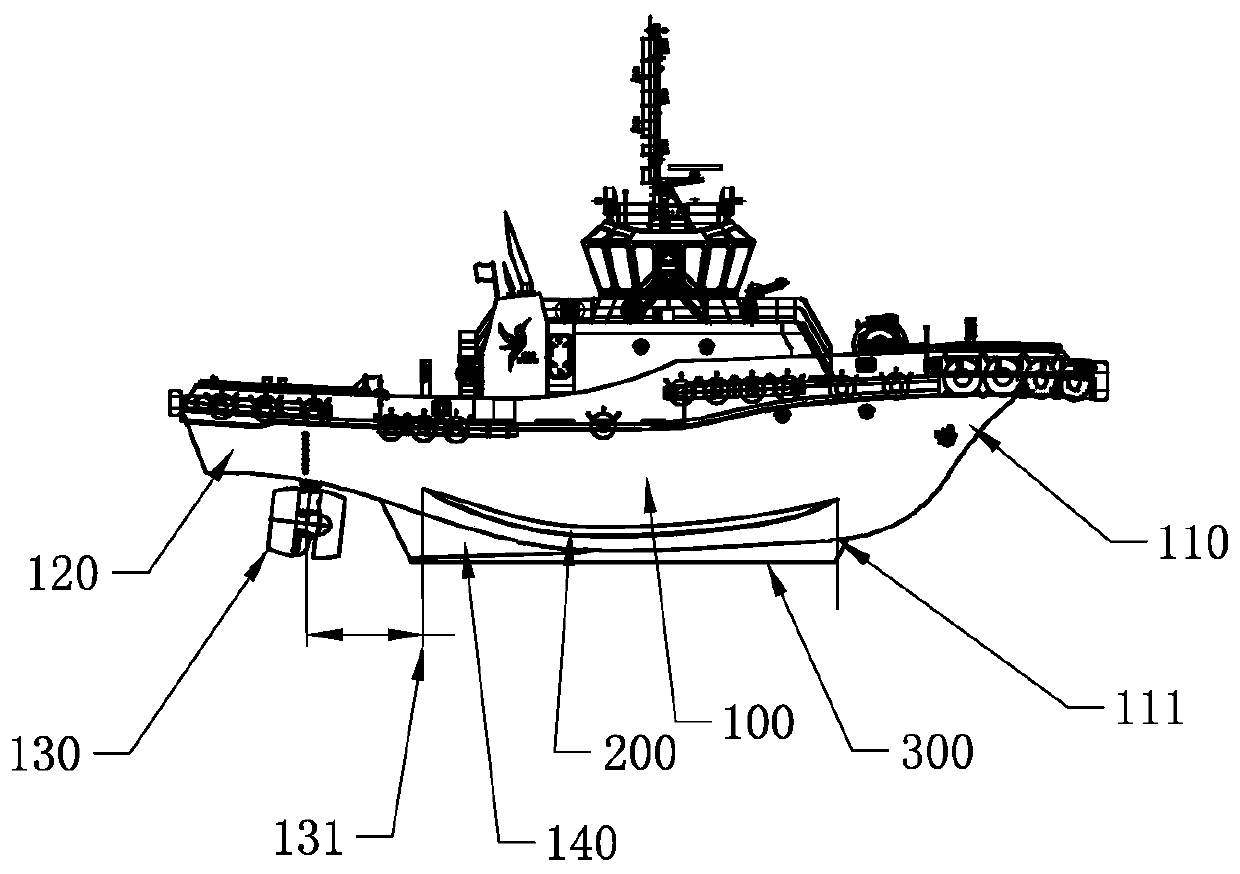

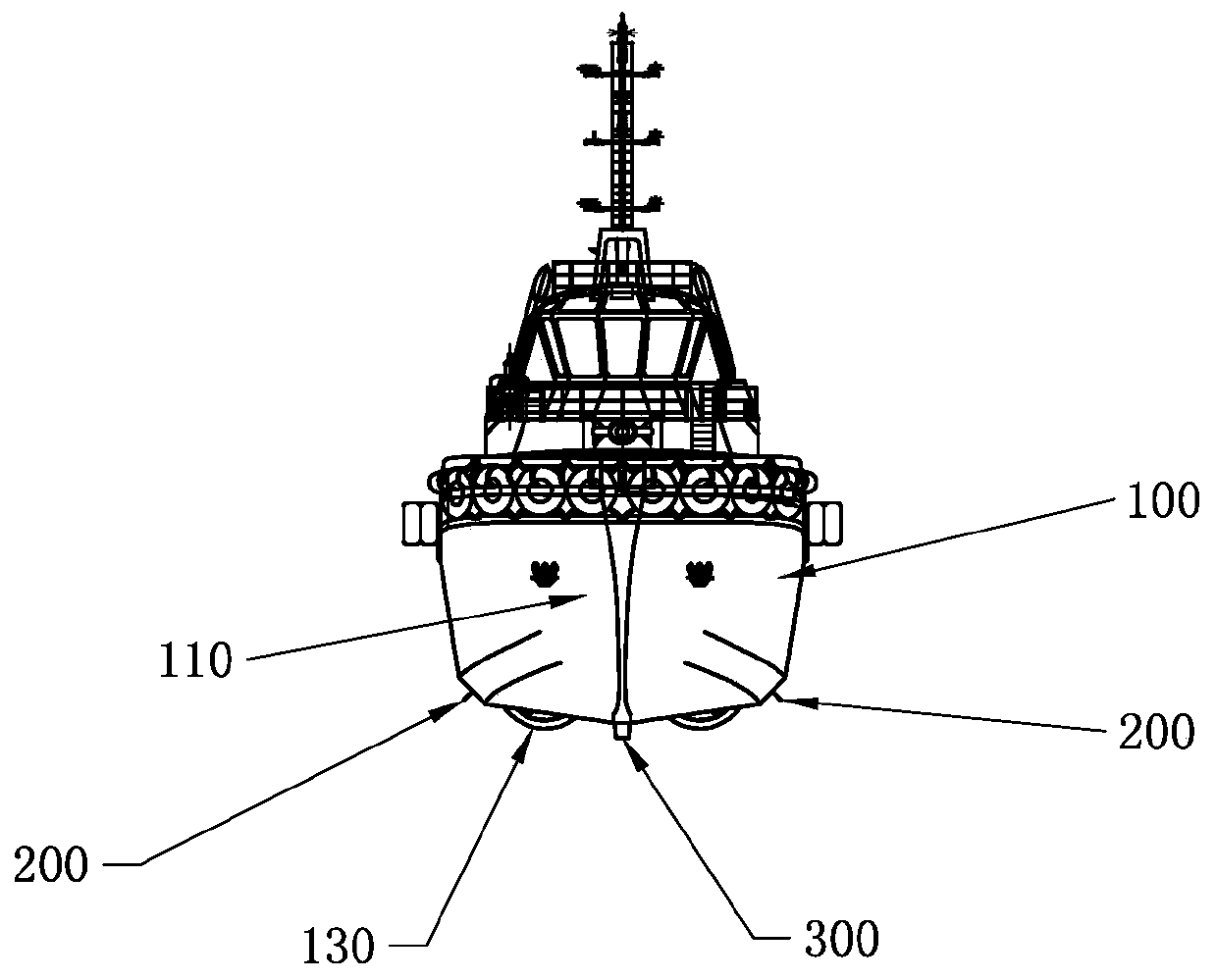

Anti-swing full-rotation tugboat capable of enhancing course stability

PendingCN111017129AIncrease dampingEnhanced wave resistanceVessel movement reduction by foilsTugsKeelWater trap

The invention discloses an anti-swing full-rotation tugboat capable of enhancing course stability. The tugboat comprises a boat body and a bilge keel is arranged at the bilge part of the boat body; aventral fin is arranged at the center of the bottom of the boat body; and the bilge keel and the ventral fin extend along the front-back direction of the boat body. According to the anti-swing full-rotation tug capable of enhancing course stability, the bilge keel and the ventral fin are arranged at the same time to form the transverse and vertical bidirectional water pressing effect, so that boosting vortex damping is triggered; and thus on the basis of improvement of the anti-swing performance and the running stability, the reaction to rotation flexibility and ship speed increase is avoided,so that the comprehensive performance of a ship is improved.

Owner:华南造船厂(江门)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com