Positioning installation mold

A positioning installation and mold technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of long positioning and installation time, low installation accuracy, and easy deformation, so as to improve installation efficiency, improve positioning and installation accuracy, reduce Effect of installation error and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

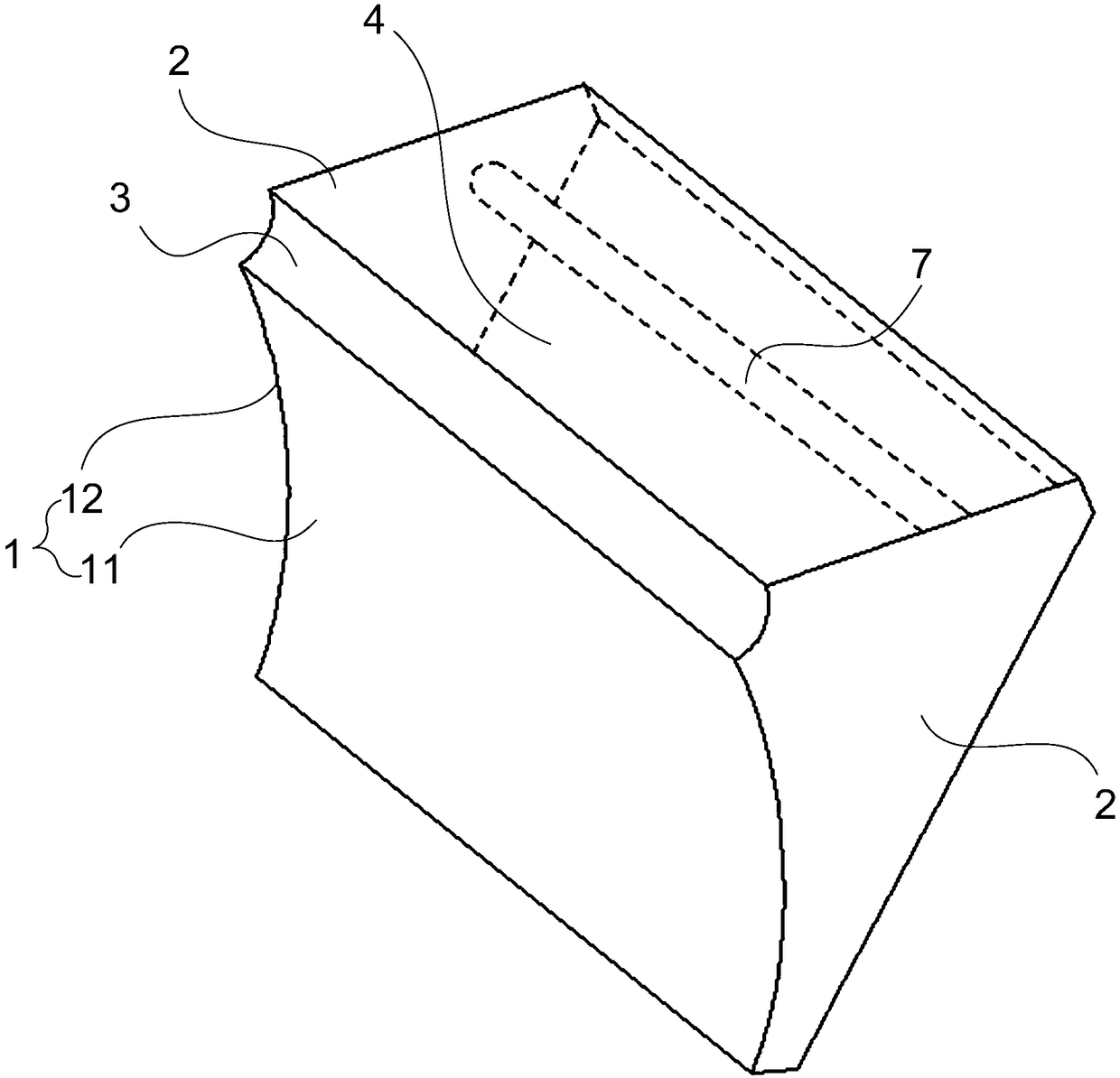

[0047] Such as figure 1 As shown, Embodiment 1 of the present invention discloses a positioning installation mold for positioning and installing the bilge keel (not shown in the figure) on the bilge part of the hull (not shown in the figure); the positioning installation mold includes an arc Plate 1, positioning part and two supporting plates 2, the two supporting plates 2 are respectively connected to the arc segments 11 at both ends of the arc-shaped plate 1, the positioning part is connected between the two supporting plates 2, and the positioning part is connected to the arc-shaped plate 1; The arc surface section 12 of the arc plate 1 matches the shape of the outer surface of the bilge and the arc plate 1 is attached to the bilge, the plane where the positioning portion is located passes through the center of curvature of the outer surface of the bilge, and the positioning portion and the bilge keel align.

[0048] Specifically, compared with the middle area of the hul...

Embodiment 2

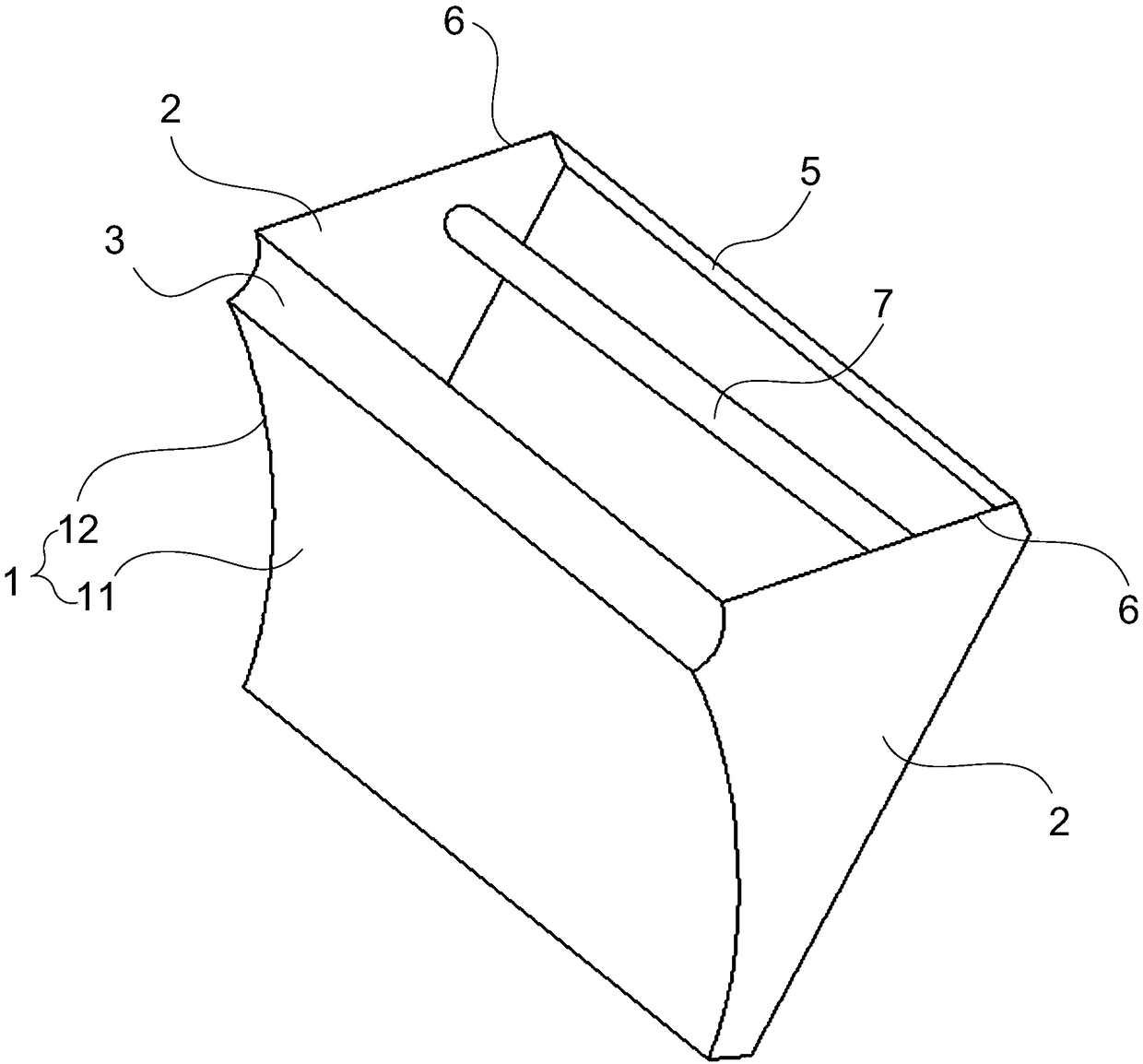

[0065] Such as figure 2 As shown, Embodiment 2 of the present invention discloses a positioning installation mold.

[0066] In this embodiment, part of the structure of the positioning installation mold is the same as that of the positioning installation mold in Embodiment 1, the difference is that the positioning part is designed as a hollow structure.

[0067] In the positioning installation mold of this embodiment, the positioning part includes a connecting rod 5 and two straight segments 6, the straight segment 6 corresponds to the supporting plate 2 one by one and the straight segment 6 is arranged on the supporting plate 2, and the connecting rod 5 is arranged on the positioning part At one end away from the arc-shaped plate 1 , a connecting rod 5 is connected between two straight sections 6 .

[0068] The positioning part is set as the structure of the connecting rod 5 and the two straight sections 6, so as to ensure the basic positioning installation and the function...

Embodiment 3

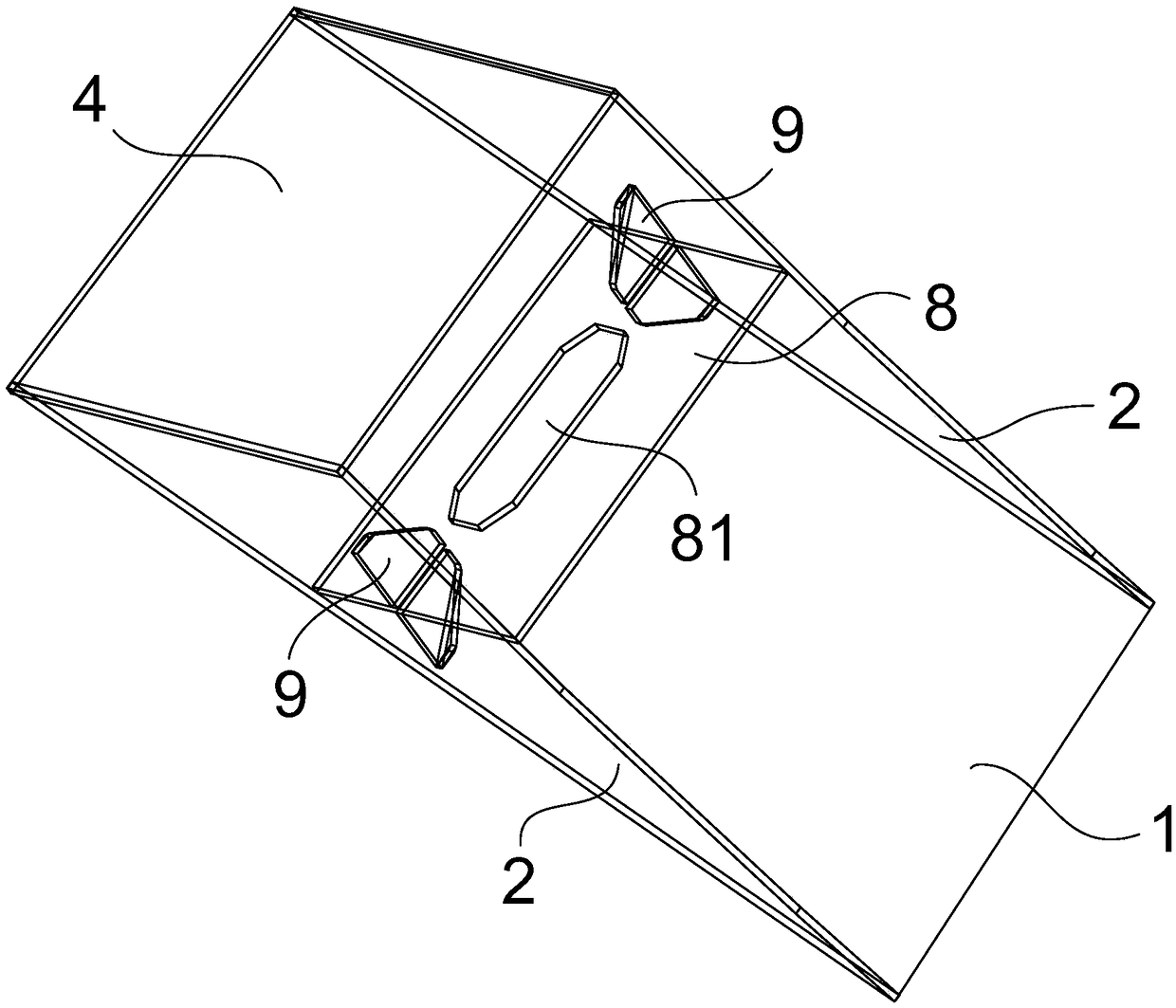

[0070] Such as image 3 As shown, Embodiment 3 of the present invention discloses a positioning installation mold.

[0071] In this embodiment, part of the structure of the positioning and installation mold is the same as that of the positioning and installation mold in Embodiment 1, the difference is that the gripping part is a plate-shaped structure.

[0072] In the positioning and installation mold of this embodiment, the gripping part is a reinforcing plate 8 , and a through hole 81 for gripping is opened in the reinforcing plate 8 , and both ends of the reinforcing plate 8 are respectively connected to the support plate 2 through a reinforcing piece 9 .

[0073] The grip part is designed as a plate structure with a through hole 81 to increase the strength between the grip part and the two support plates 2, and avoid the defect that the positioning and installation mold itself deforms after repeated use, resulting in a decrease in positioning and installation accuracy.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com