Bilge for ocean engineering auxiliary ship

A technology for marine engineering and auxiliary ships, which is applied in the direction of hull parts, hulls, and ship construction, and can solve the problems of unfavorable anti-roll control, increased construction cost, and high cost of anti-rolling fins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

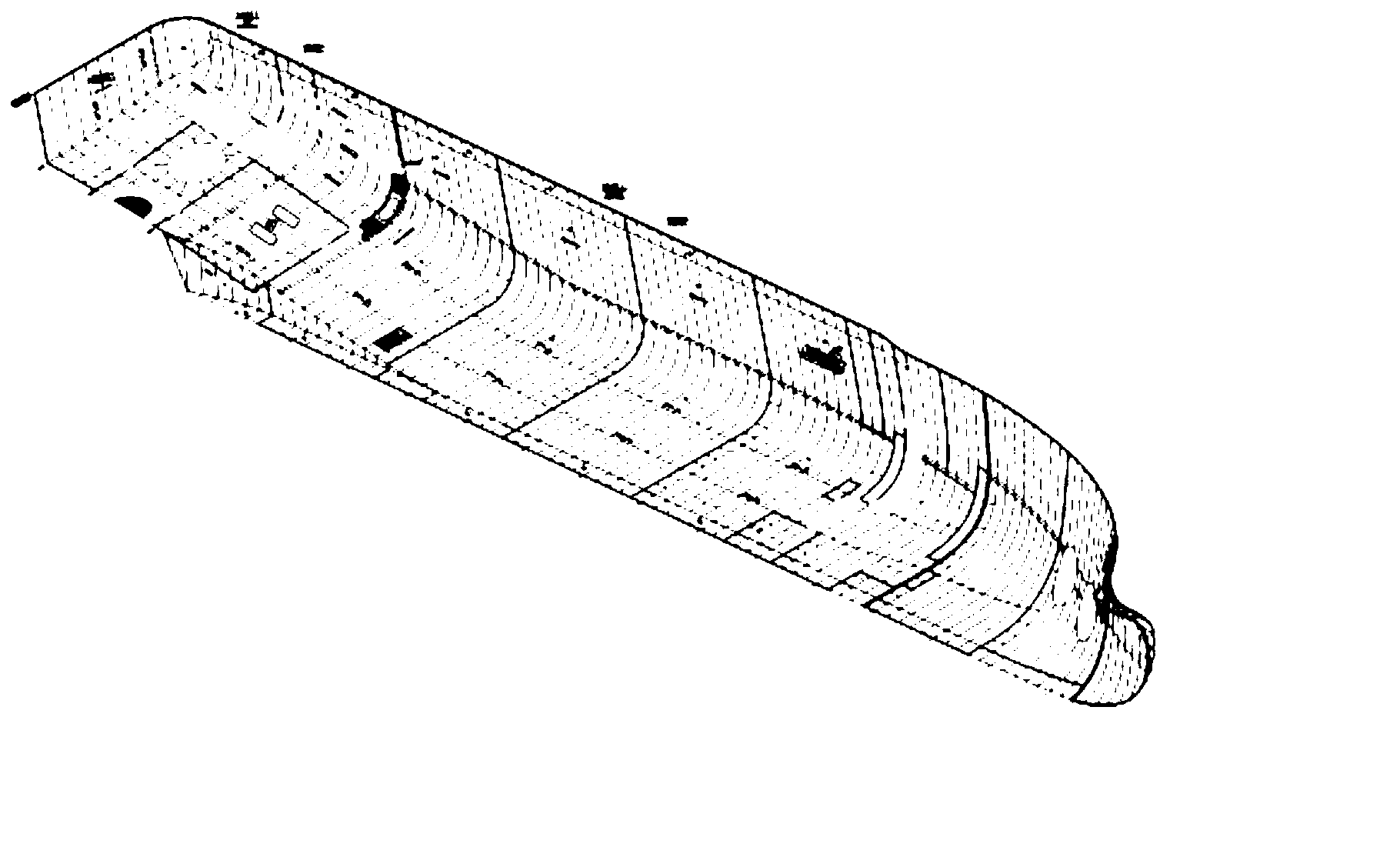

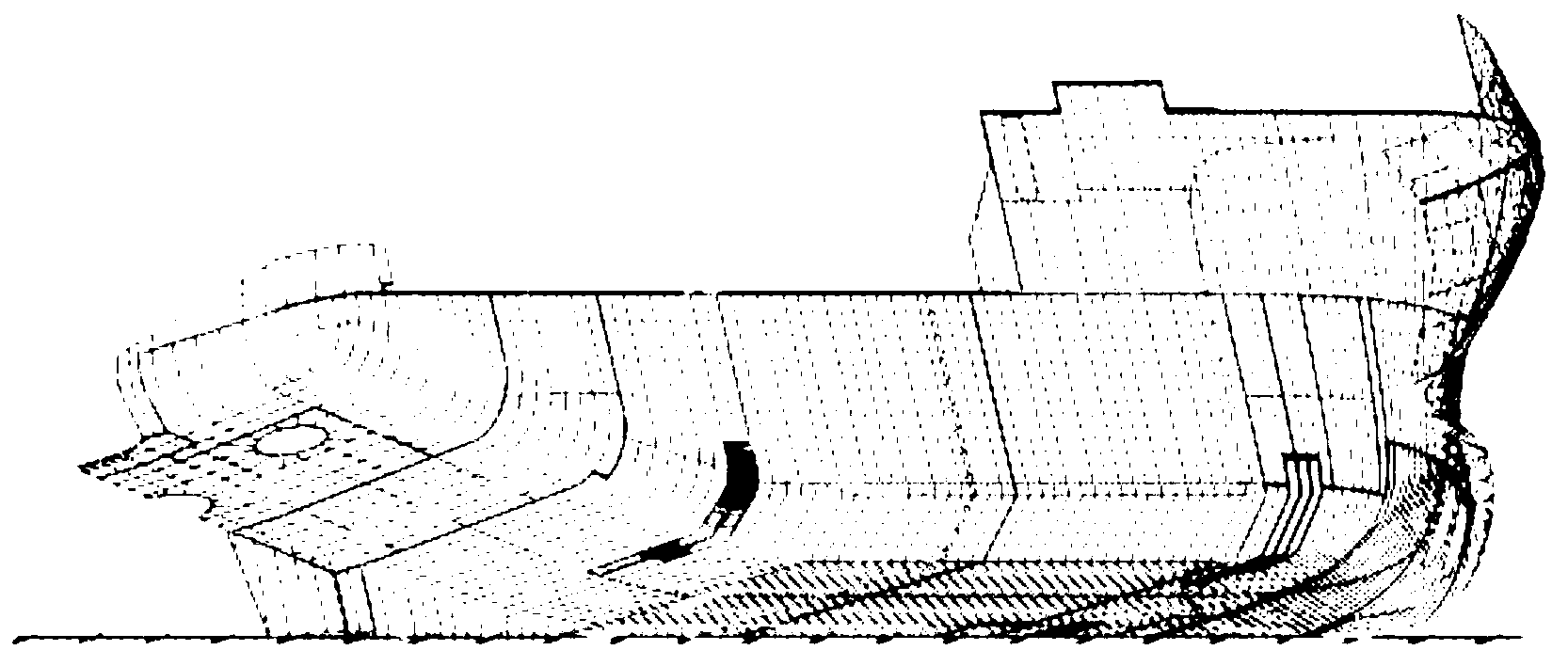

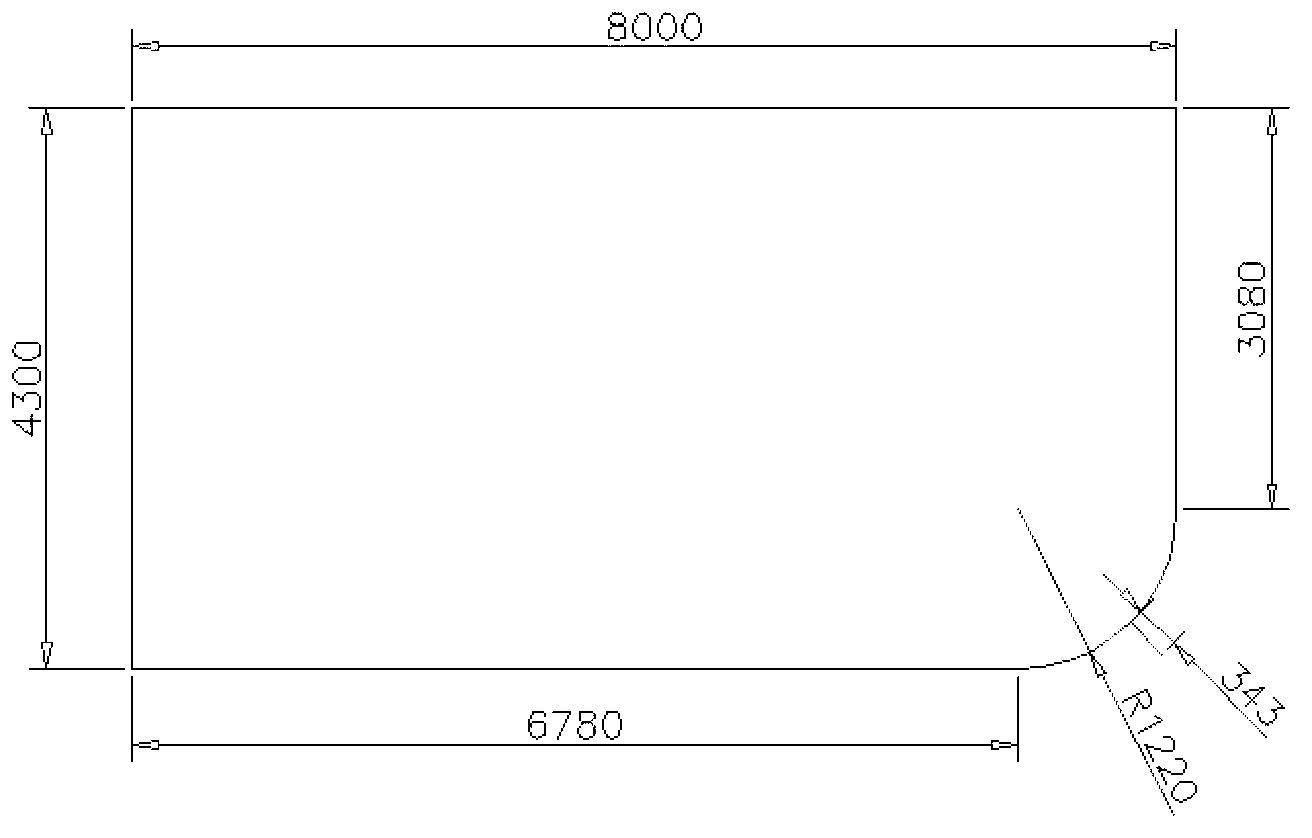

[0028] An existing marine engineering auxiliary vessel such as figure 1 As shown, this type of ship is called Plan A, and the traditional arc-shaped bilge at the parallel center body is changed to the angle-shaped bilge of the present invention, and the head and tail sections are transitioned to the arc-shaped bilge, as figure 2 As shown, this type of ship is called Plan B, and the main parameters of the two plans are listed in the following table:

[0029] Table 1. Main parameter information of the two schemes

[0030]

[0031]

[0032] Combining the shape of the bilge part of the two schemes, the layout of the bilge keel is carried out. According to the usual practice, the layout of the bilge keel should not exceed the width of the ship and the bottom of the ship....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com