Cooling method and apparatus for cooling circulating water of glass fibre reinforced plastic ship internal-combustion engine

A technology for cooling circulating water and FRP boats, which is applied in the directions of hull ventilation/heating/cooling, propulsion engine, ship propulsion, etc. Minor problems, good cooling effect, no influence on the speed of the ship, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

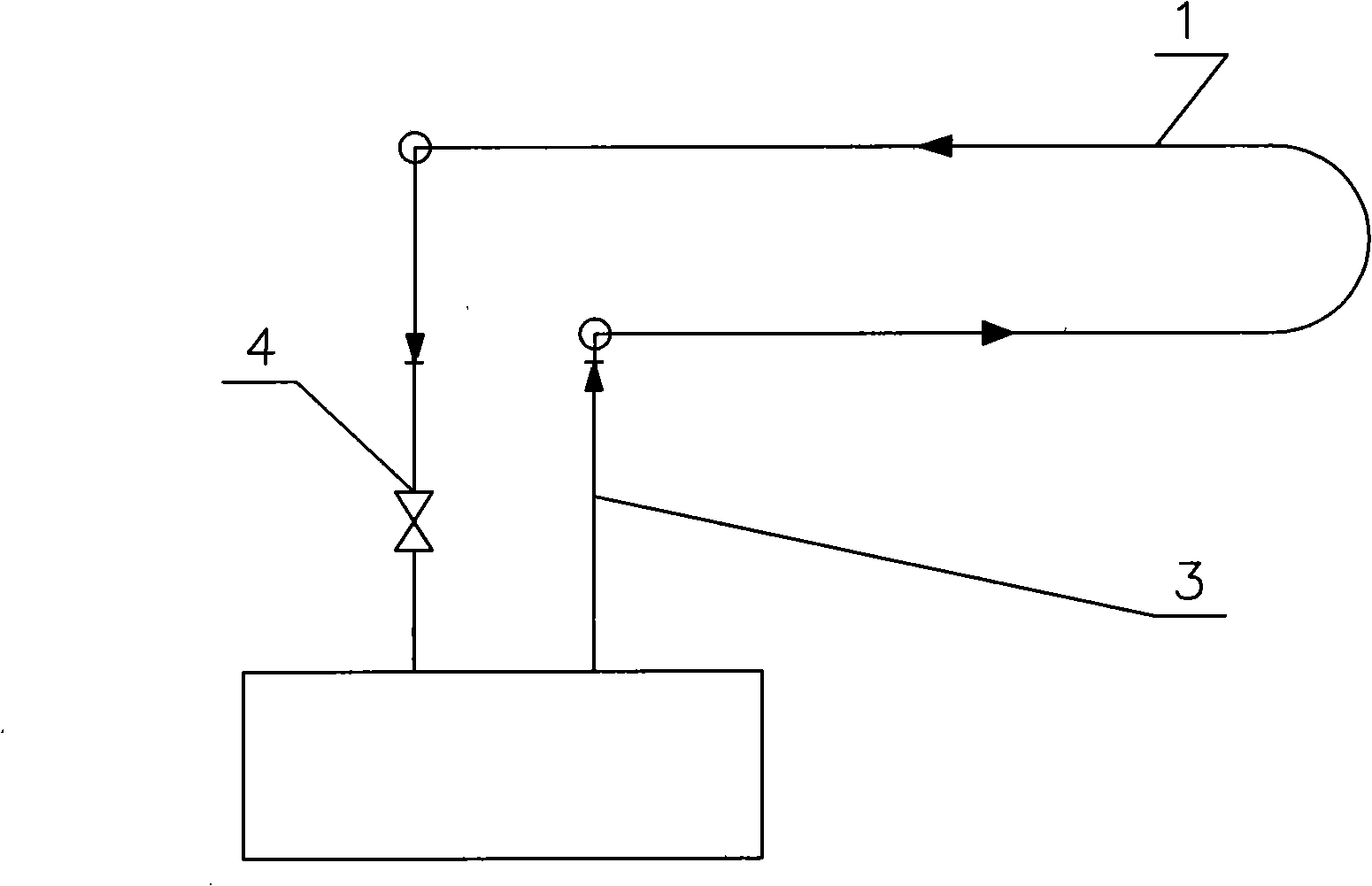

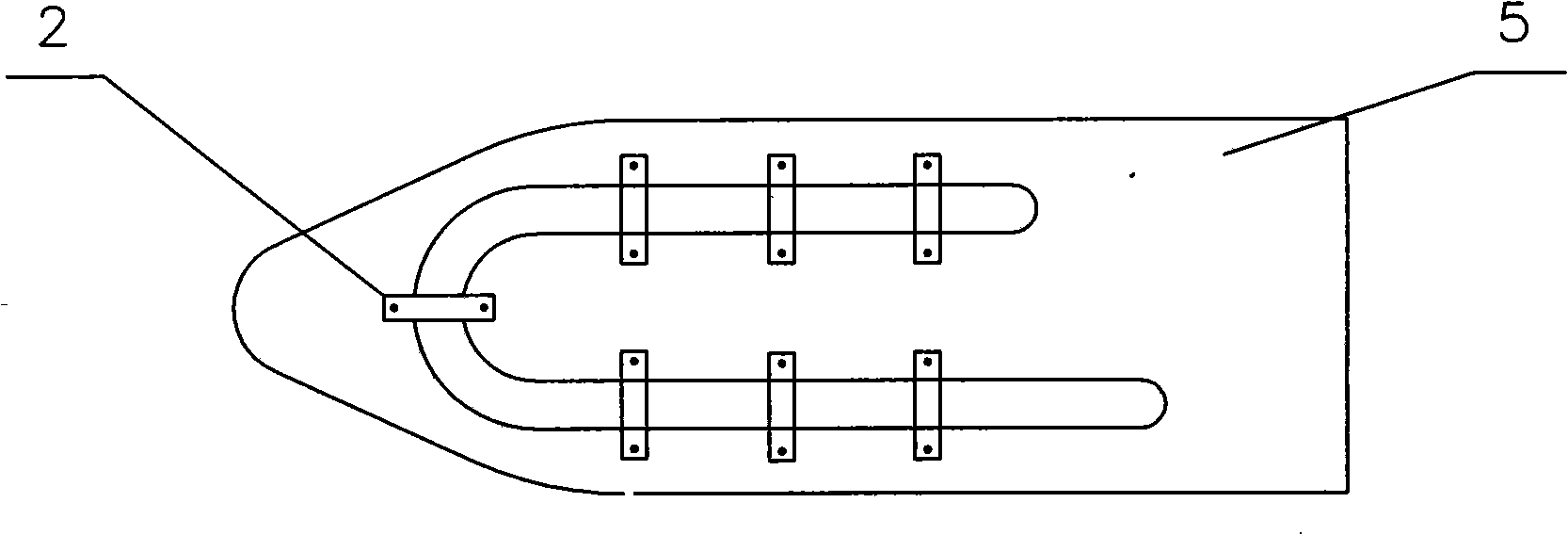

[0011] The present invention will be further described below in conjunction with the accompanying drawings:

[0012] As shown in the figure, a cooling method for cooling circulating water of internal combustion engine of a glass fiber reinforced plastic ship is characterized by lofting according to the line type of the hull plate on both sides of the bottom keel, and then bending the cooling coil 1 that is consistent with the line type of the hull plate. , And then directly assembled on the outer side of the hull shell plate on both sides of the bottom keel through the coil pipe clamp code 2. One end of the cooling coil 1 is connected with the outlet pipe of the power unit, and the other end of the cooling coil 1 is connected with the fresh water pump inlet of the power unit Connected to form a closed cooling system. The heat of the fresh water in the tubular outboard cooler is taken away by the outer seawater, which has the effect of cooling the fresh water. The cooled fresh wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com