Three-dimensional modeling method for bilge keel structure and bilge keel structure

A three-dimensional modeling, bilge keel technology, applied in 3D modeling, image data processing, instruments, etc., can solve the problems of inability to achieve accurate modeling, inaccurate calculation of the weight center of gravity, large deviation of bilge keel structural parts, etc. The effect of calculating accuracy, avoiding deviations, and improving structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

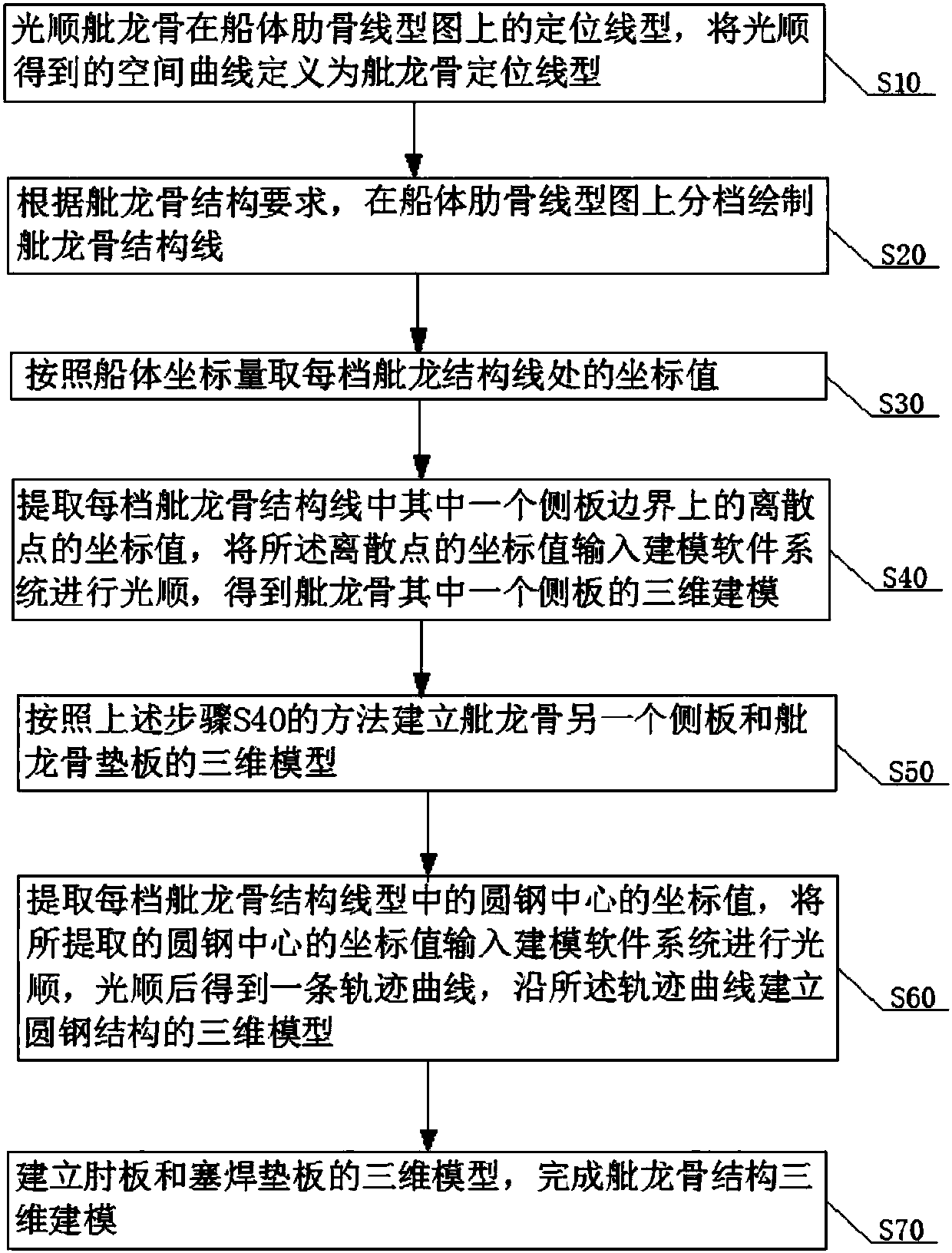

[0035] A three-dimensional modeling method for a bilge keel structure, comprising the following steps,

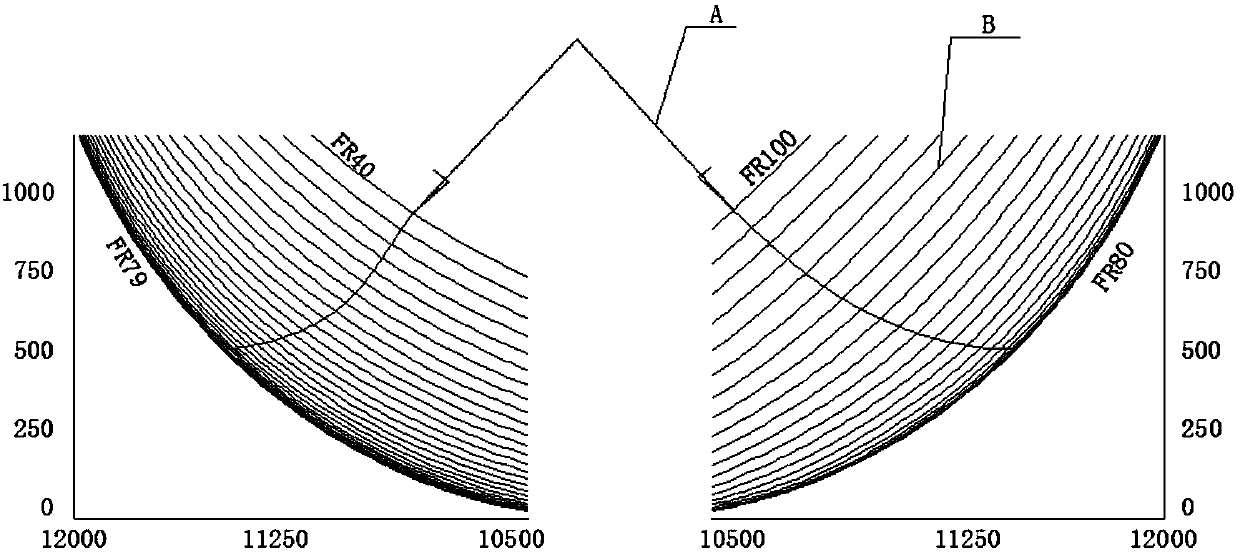

[0036] S10, smoothing the bilge keel positioning line type A on the hull frame line shape diagram, define the space curve obtained by smoothing as the bilge keel positioning line type, as shown in figure 2 Shown; As a preferred solution, the positioning line is the center line of the bilge keel on the hull rib line diagram.

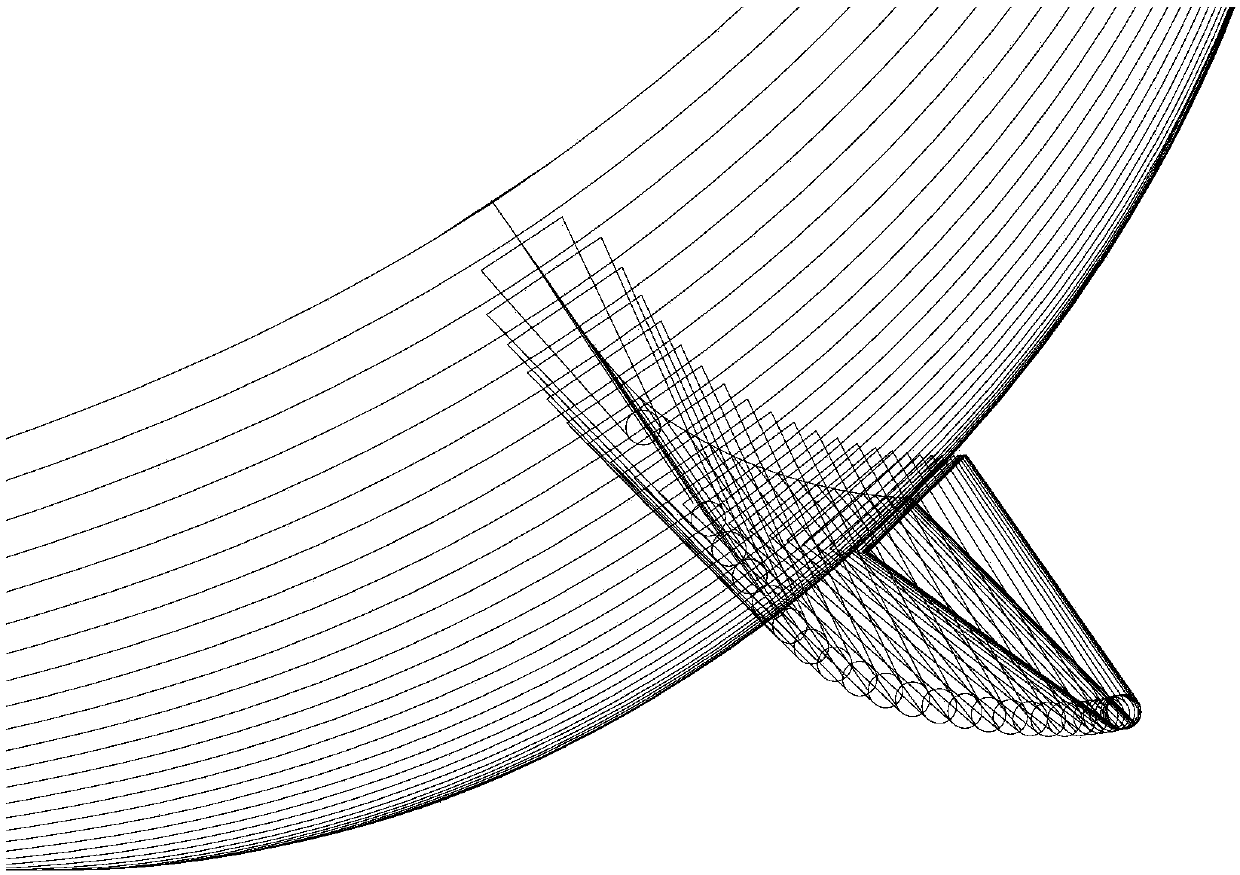

[0037] S20. According to the requirements of the bilge keel structure, draw the bilge keel structure line in stages on the line diagram of the hull ribs; as an optimal solution, such as image 3 As shown, taking the rib line type B of the hull a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com