Novel intelligent resistance-reducing bilge keel

A bilge keel and intelligent technology, which is applied in the field of new intelligent drag-reducing bilge keel, can solve the problems of increased resistance, inconsistent hull surface streamlines, complicated navigation and working conditions, etc., and achieve the effect of reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

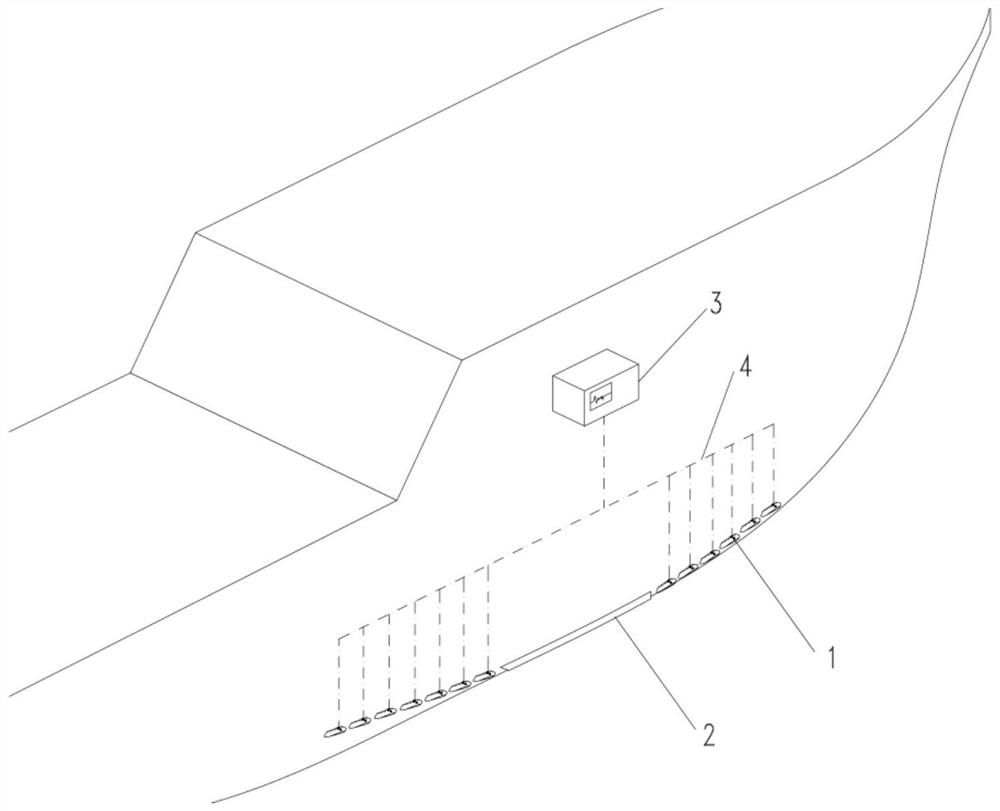

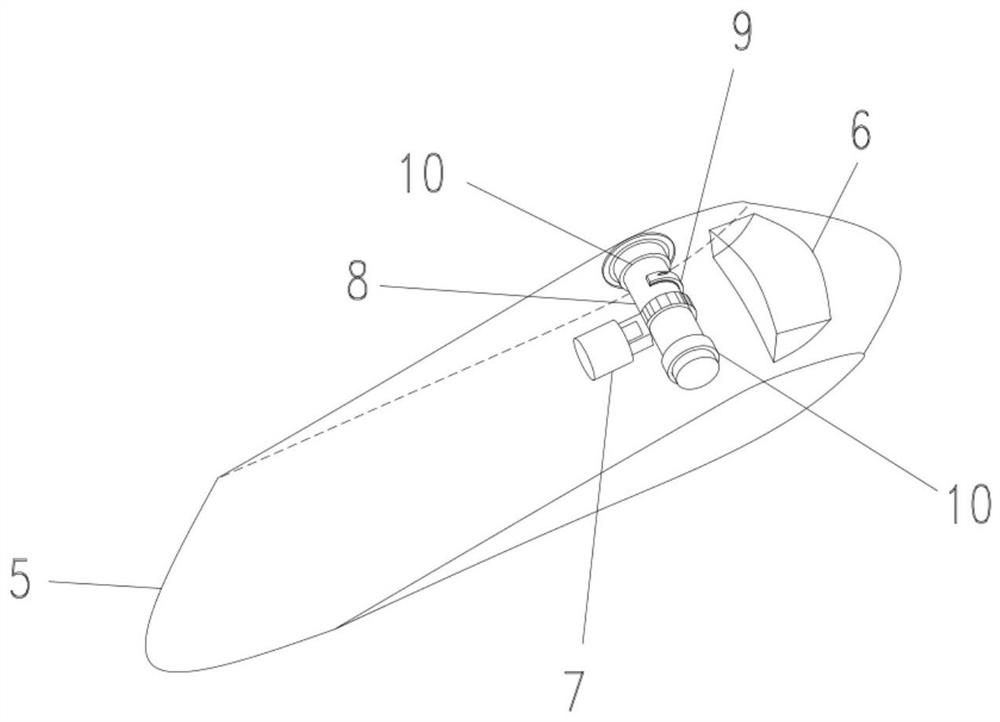

[0024] Such as figure 1 As shown, this application proposes a new type of intelligent drag-reducing bilge keel, which transforms a part of the conventional fixed bilge keel into multiple discrete leaf-shaped bilge keels that can intelligently adjust the angle, which can reduce the The increased resistance caused by the inconsistency between the direction of the bilge keel and the streamline. The novel intelligent drag-reducing bilge keel includes a conventional bilge keel part 2 , a discrete bilge keel part and an intelligent control module 3 . The conventional bilge keel part 2 has no difference in design from the conventional bilge keel, but it is only arranged in the parallel mid-body part, or the part where CFD calculation or model experiment proves that there is no difference in streamline under various working conditions of the bilge. The discrete bilge keel part is set at the part where the CFD calculation or model experiment proves that the streamlines are different u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com