Mounting and positioning method for bilge keel

A technology for installing positioning and bilge keels, which is applied in transportation and packaging, equipment for reducing ship movement, and ship parts, etc. It can solve problems such as poor anti-rolling effect of ships and improper installation of bilge keels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

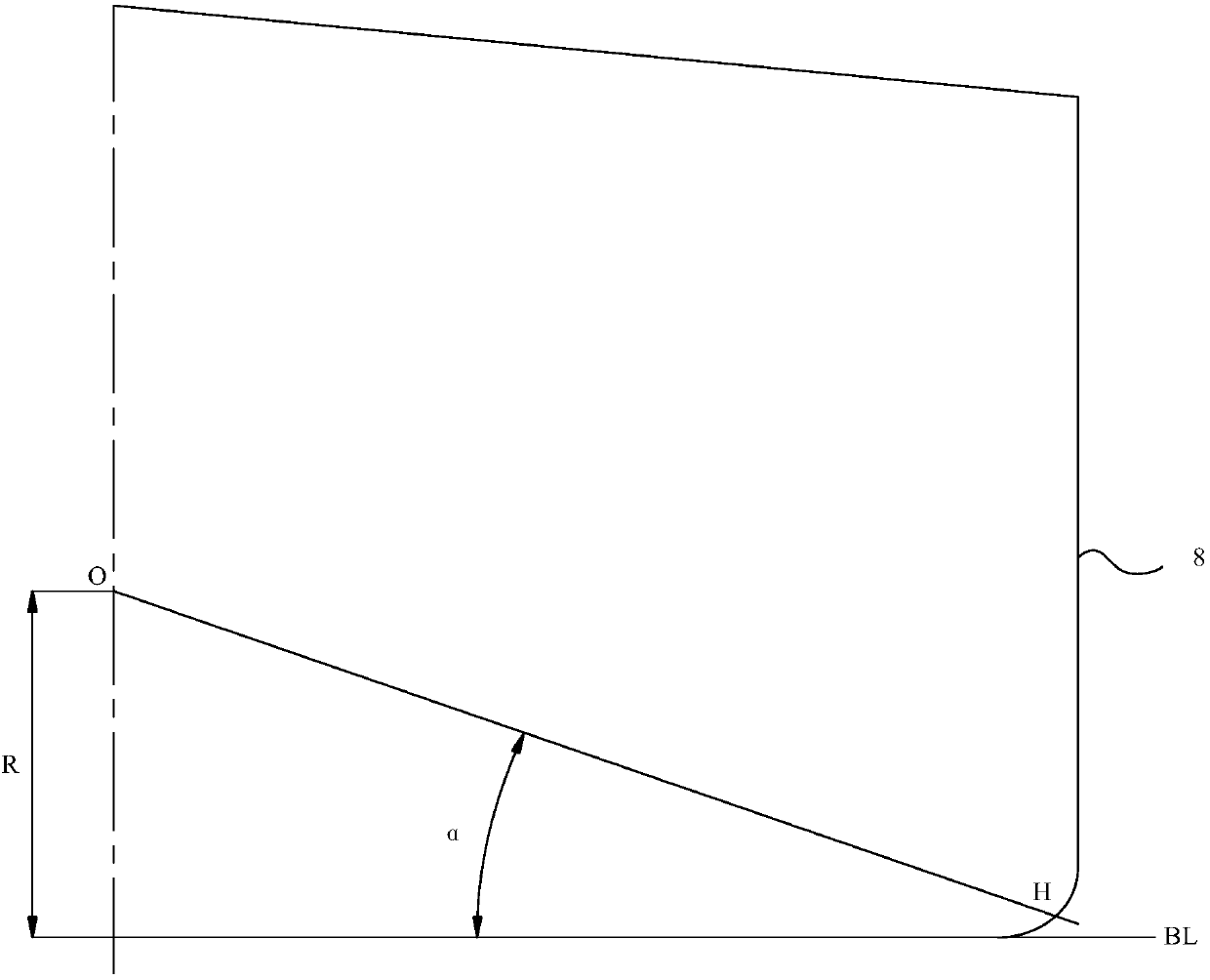

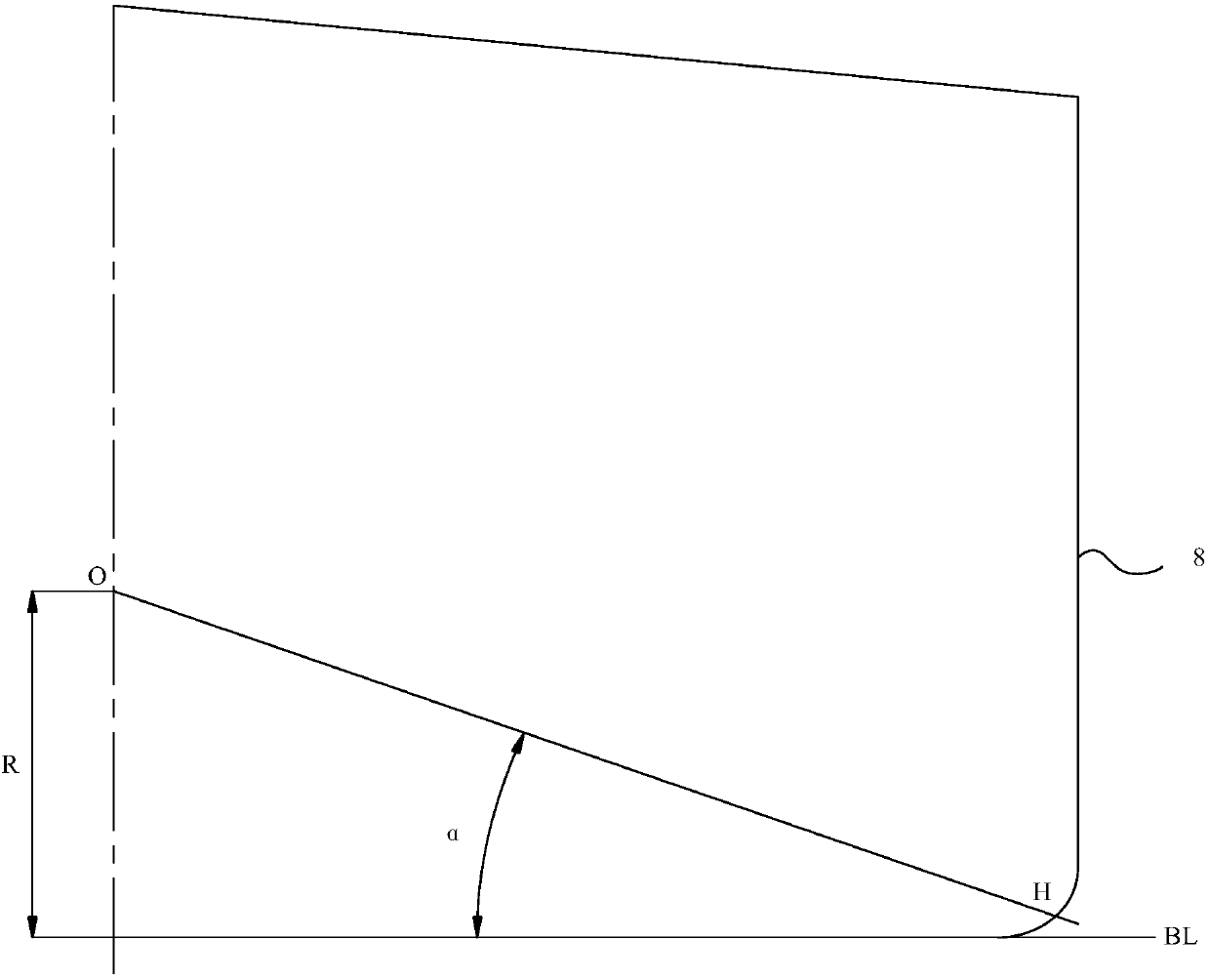

[0021] Such as figure 1 As shown, the installation and positioning method of the bilge keel includes the following steps:

[0022] S1: In the cross-sectional view of the hull, connect the bilge keel installation point H and the roll center point O of the ship;

[0023] S2: The angle formed by the connecting line OH between the installation point H of the bilge keel and the roll center point O of the ship and the baseline BL is the bilge keel positioning angle α, and the baseline BL is the tangent line between the transverse section of the hull and the inner surface of the bottom plate;

[0024] S3: Install the bilge keel according to the positioning angle of the bilge keel;

[0025] Wherein, the height R of the rolling center point from the baseline is calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com