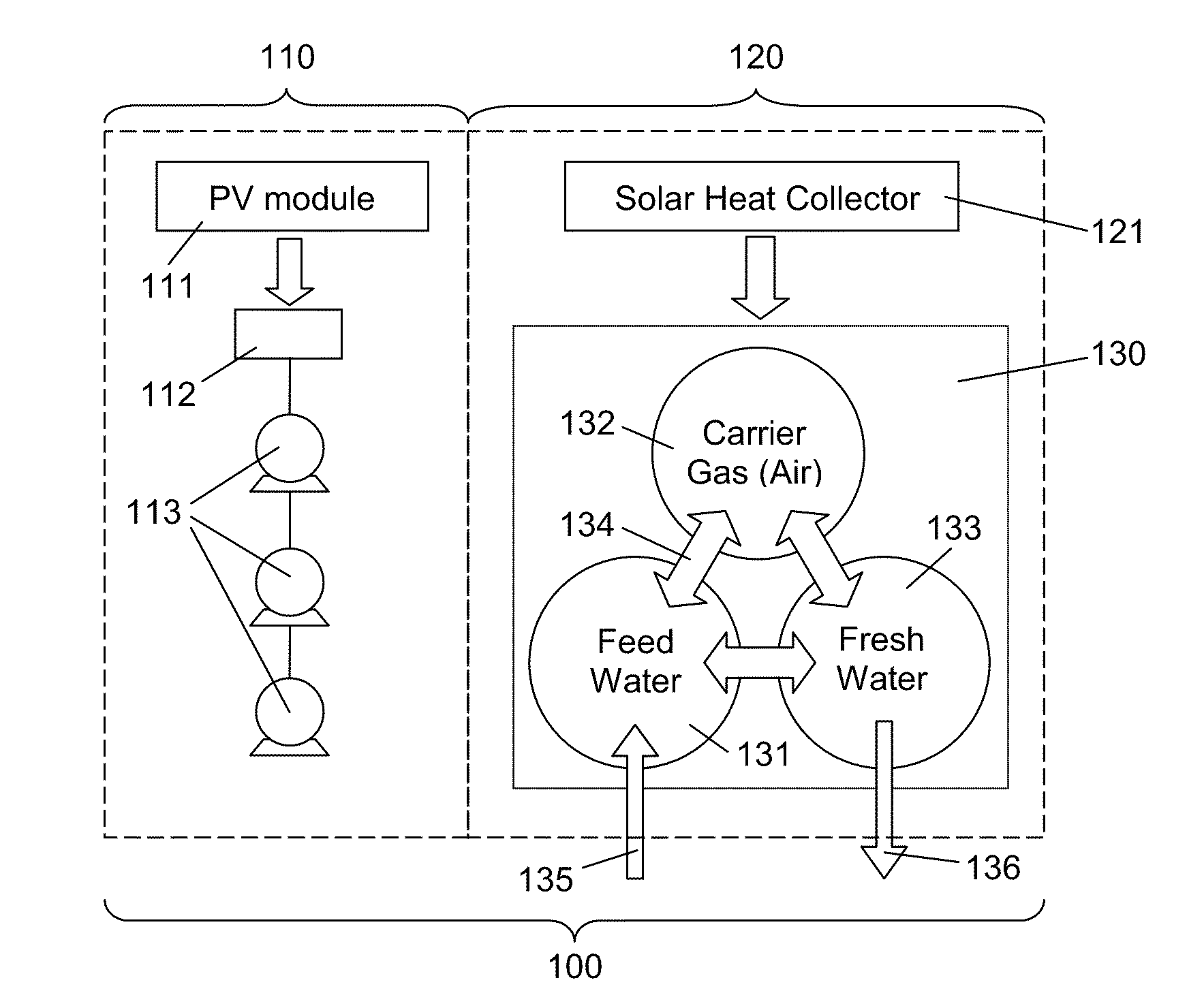

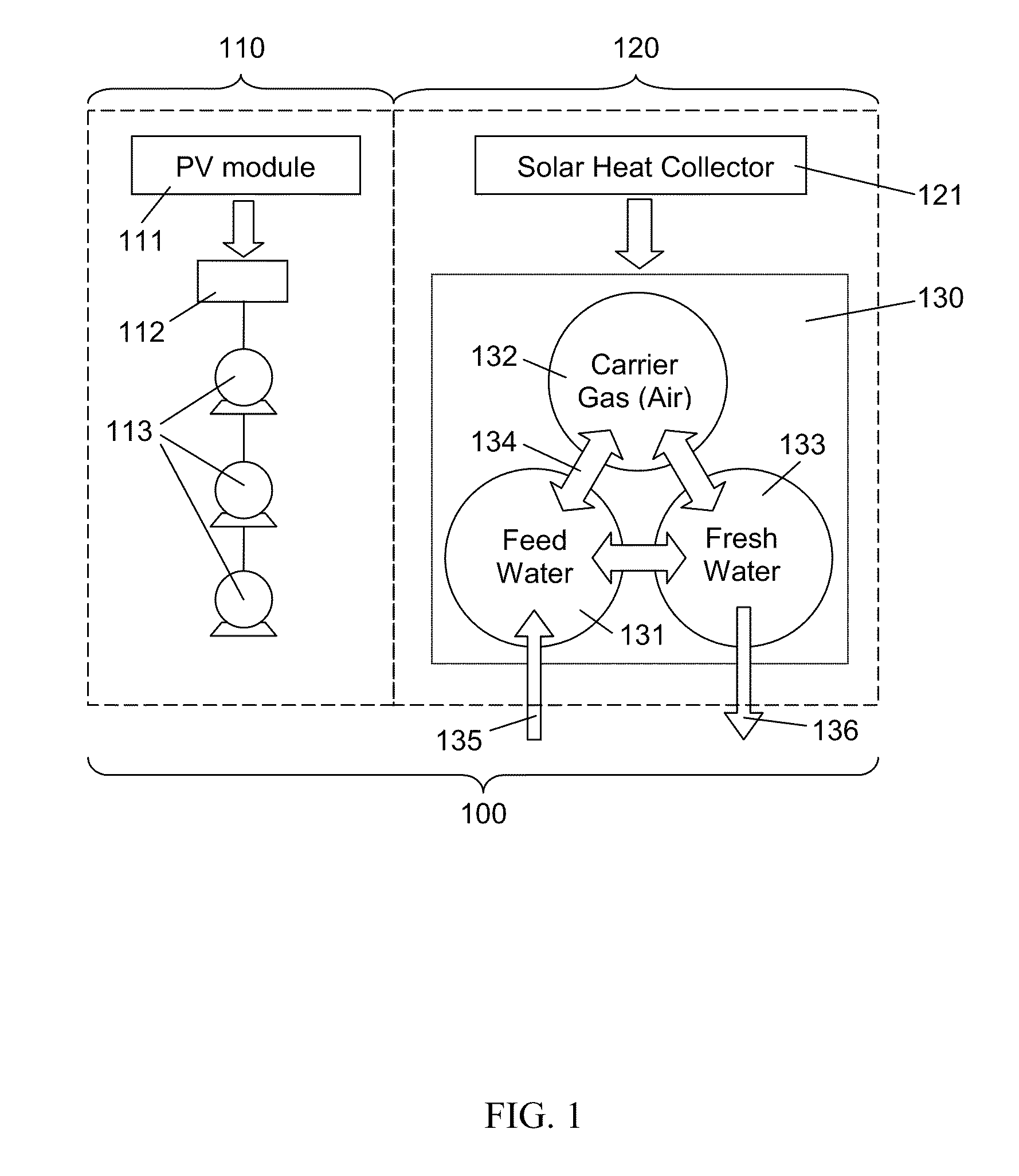

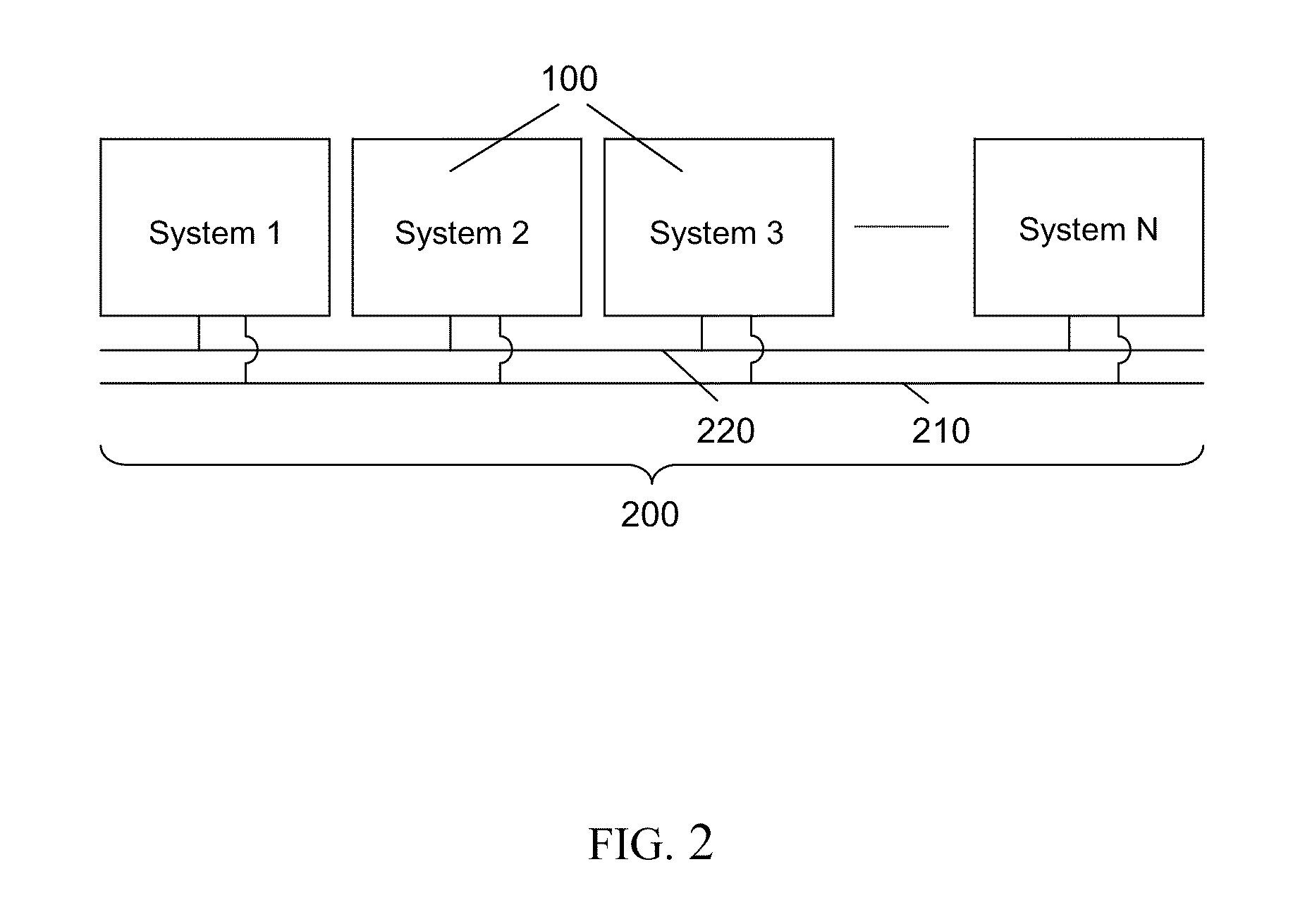

Hybrid solar desalination system

a solar energy and desalination system technology, applied in vacuum distillation separation, vessel construction, separation processes, etc., can solve the problems of low productivity rate and thermal efficiency, difficult to implement any traditional clean water solution, and insufficient money and oil resources of people in many other areas of the world

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0062]In accordance with the present invention, an apparatus for aeration-assisted mass exchange, e.g. evaporation and condensation, can be provided. It includes a cylindrical container and a disk shaped aerator as shown in FIG. 15. The container can be produced from stainless steel, PVC or other container material suitable for processing of potable water. The diameter of a container may be in the range of 1 cm to 1 m, preferably in the range of 10 to 20 cm, whereas the height of the container may be in the range of 2 cm to 2 m, preferably in the range of 10 to 40 cm. The diameter of the aerator may be about the diameter of the container. The aerator may have a dense array of holes having a diameter in the range of 0.1 to 5 mm, preferably 0.5-2 mm, and the spacing between nearest holes in the range of 0.1 to 5 mm. The apparatus may also include a stack of screens that are made of a stainless steel wire mesh or plastic fibers. Screens may be less than 1 mm thick, preferably less than...

example 2

[0065]In accordance with the present invention, an apparatus for wetscreen-assisted mass exchange, e.g. evaporation and condensation, can be provided. It includes a container and a stack of see-through screens as shown in FIG. 22. The container can be produced from stainless steel, PVC or other container material suitable for processing of potable water. The container may be square in the cross-section having a side size in the range of 1 cm to 1 m, preferably in the range of 10 to 20 cm, whereas the height of the container may be in the range of 2 cm to 2 m, preferably in the range of 10 to 40 cm. The size of the screens may be about the size of the container. The screens may be staggered to provide a passage for the air flow between them, so that some of them have a wide opening for air passage on the right side, while others have an opening on the left side. They may be made of a stainless steel wire mesh, plastic fibers, thin sponge or perforated sheets of other water-safe mater...

example 3

[0068]In accordance with the present invention, an HTS apparatus of a desalination system may be provided as shown in FIG. 9. The apparatus comprises a solar heat collector, an evaporator, a condenser and a heat exchanger. Feed water is provided to the apparatus from a salt or brackish water source, e.g. an ocean or a pond. This water is preheated using a counter-current heat exchanger, e.g. a shell-and-tube heat exchanger produced by Exergy LLC, and then further heated using a solar heat collector, e.g. an FPC panel produced by Schuco USA having an absorber area in the range of 2-3 m2. Multiple collector panels may be used in a single HTS and also, other types of heat collector may be used instead of FPC panels, such as evacuated tubes or concentrated solar collectors. The heated feed water is then fed to the evaporator at a temperature Tin in the range of 50° C. to 100° C., preferably in the range of 80° C. to 99° C. The evaporator may be provided using the apparatus described eit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

| Solar energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com