MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater

A technology for evaporating crystallization and high-salt wastewater, applied in evaporation, multi-effect evaporation, separation methods, etc., can solve the problems of low crystallization salt quality, poor crystallization effect, high equipment cost, etc., achieve reasonable process, facilitate continuous production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

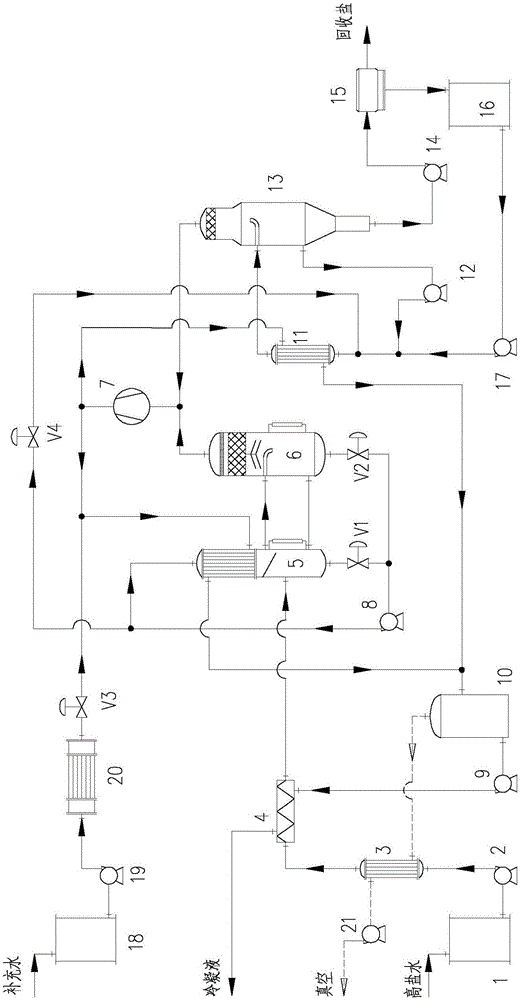

[0041] A mechanical vapor recompression evaporation crystallization system for high-salt wastewater:

[0042] Including raw material tank 1, raw material pump 2, first preheater 3, second preheater 4, MVR evaporator 5, gas-liquid separator 6, compressor 7, first circulating pump 8, condensate pump 9, condensation Liquid tank 10, forced circulation evaporator 11, second circulation pump 12, crystallizer 13, salt pump 14, centrifuge 15, mother liquor tank 16, mother liquor pump 17, clean water tank 18, clean water pump 19, steam generator 20 and Vacuum pump 21;

[0043] The raw material tank 1 is connected to the inlet of the raw material pump 2, and the outlet of the raw material pump 2 is connected to the first preheater 3 and the second preheater 4 in sequence through a pipeline, and the material liquid outlet of the second preheater 4 is connected to the MVR evaporator 5 The material and liquid inlet;

[0044] The gas-liquid mixture outlet of the MVR evaporator 5 is connected to ...

Embodiment 2

[0052] The method of using the system described in the embodiment to perform mechanical vapor recompression, evaporation and crystallization of high-salt wastewater includes:

[0053] The high-salt wastewater in the raw material tank 1 is sent to the first preheater 3 through the raw material pump 2, where it exchanges heat with non-condensable steam in the first preheater 3, and then enters the second preheater 4 and condensate Perform heat exchange and increase temperature, and increase the temperature to 80~90℃ under the effect of heat exchange of condensate;

[0054] The heated hot liquid enters the MVR evaporator 5, where it exchanges heat with the secondary vapor compressed by the compressor 7, and reaches the evaporation temperature to form a large amount of gas-liquid mixture and concentrated liquid, where the gas-liquid mixture enters Gas-liquid separation is performed in the gas-liquid separator 6, and concentrated liquid and secondary steam are obtained in the gas-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com