Integrated forced circulation crystallizing evaporator for producing large-grained ammonium sulfate and device

A forced circulation crystallization and evaporator technology, applied in forced circulation evaporators, evaporator accessories, evaporation, etc., can solve the problems of large floor space and poor layered staying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

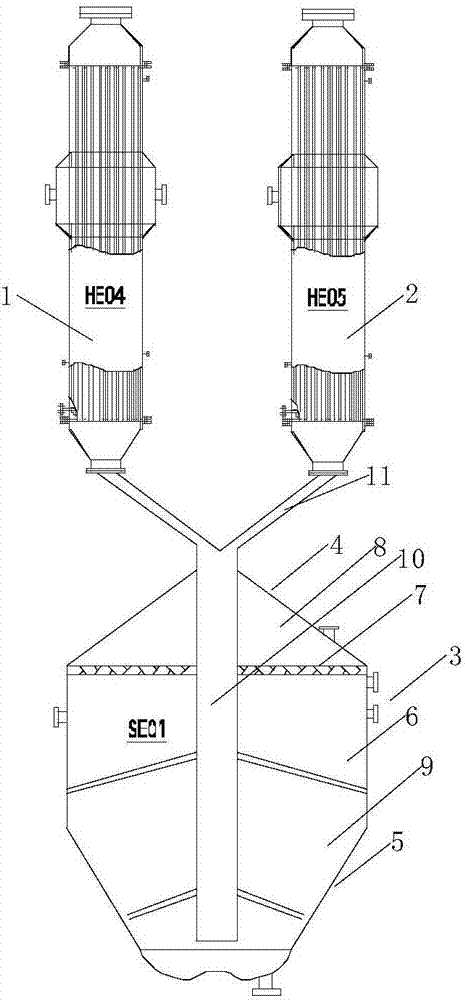

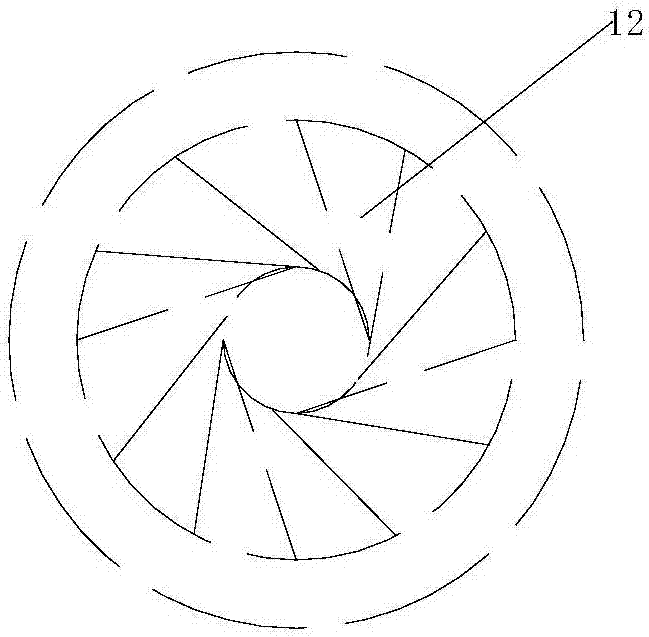

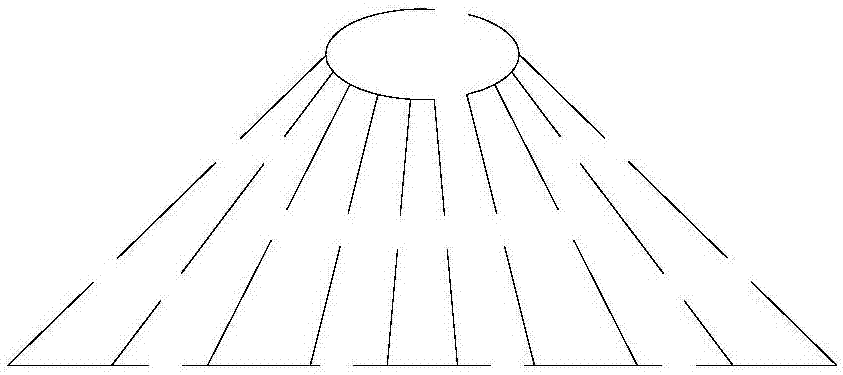

[0019] see figure 1 Shown, the one-piece forced circulation crystallization evaporator of producing large grain ammonium sulfate is characterized in that, comprises first evaporator 1, second evaporator 2 and crystallizer 3; Described crystallizer connects the first evaporator successively from top to bottom A conical portion 4, a cylindrical portion 6 and a second conical portion 5; the junction of the first conical portion and the cylindrical portion is provided with a (welding) wire mesh demister 7, and the wire mesh demister will The crystallizer is divided into a vaporization chamber 8 and a crystallization chamber 9; the taper of the second tapered portion is greater than the taper of the first tapered portion; the crystallizer is provided with (welding) a first draft tube 10, the first The draft tube protrudes from the top of the crystallizer and is respectively connected to the material outlets of the first and second evaporators through two second draft tubes 11; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com