Device system for efficient cobalt sulfate concentration and continuous crystallization

A cobalt sulfate, high-efficiency technology, applied in cobalt sulfate, steam condensation, climate sustainability, etc., can solve the problems of unenvironmental protection and economy, increase condensation equipment to condense secondary steam and condensed water, waste energy, etc., to achieve continuous The effect of automation, increase enterprise revenue, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

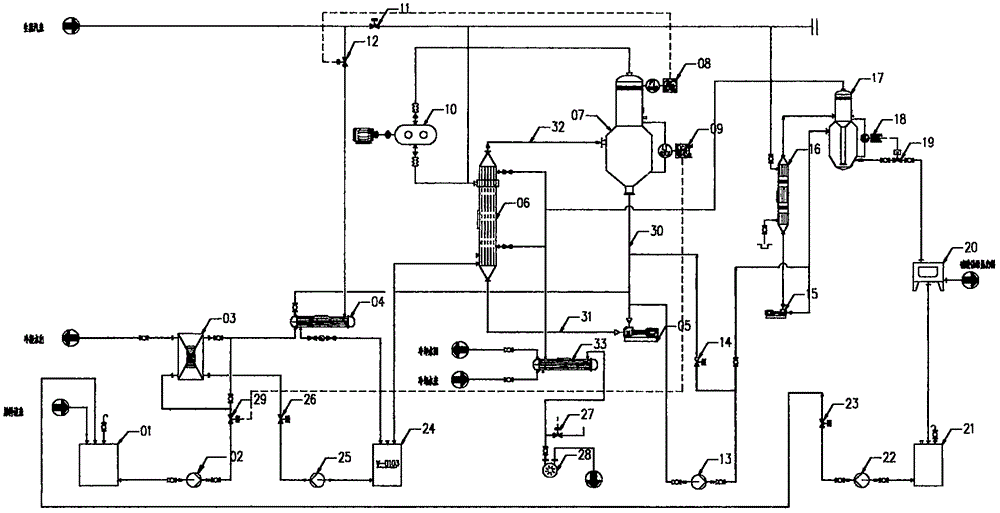

[0017] Such as figure 1 As shown, the production system for high-efficiency evaporation and continuous crystallization of cobalt sulfate includes an integrated evaporation concentration system with mechanical vapor compression and a high-efficiency crystallization system for OSLO vacuum crystallization. It is characterized in that: the bottom outlet of the stock solution buffer tank (01) It is connected to the feed pump (02), and the outlet of the feed pump is connected to the cold side inlet of the condensate preheater (03); the cold side outlet of the condensate preheater (03) is connected to the cold side inlet of the steam preheater (04). The side inlets are connected, and the cold side outlet of the steam preheater (04) is connected to the mechanical vapor recompression evaporation unit through the feed pipeline; the bottom of the separation chamber (07) of the mechanical vapor recompression evaporation unit has a discharge port, It is connected with the primary circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com