Vaporization system based on air heat insulation and humidification process

An air insulation and evaporation system technology, applied in the field of evaporation system, can solve the problems of high safety and reliability requirements of steam compressors, large equipment footprint, waste of secondary steam, etc., and achieve easy system control, high thermal efficiency, and reduced emissions Effect of smoke temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

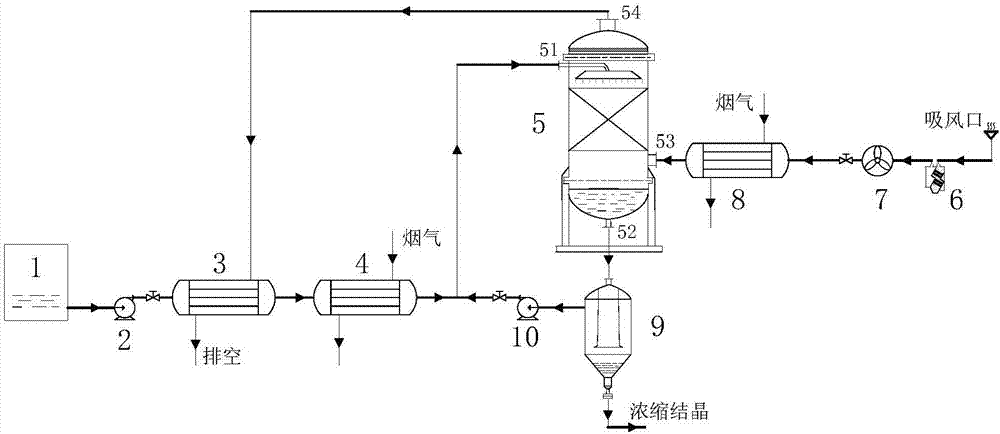

[0026] Such as figure 1 The process flow diagram of an evaporation system based on the air adiabatic humidification process is shown. The evaporation system based on the air adiabatic humidification process in this embodiment includes a raw material storage tank 1, a feed pump 2, a condensation regenerator 3, and a preheater 4 , Evaporation chamber 5, dust collector 6, fan 7, air heater 8, circulating liquid tank 9, circulating pump 10.

[0027] The following is an example of the evaporation process of high-salt wastewater, so as to understand the operation process of the whole system:

[0028] Collect the high-salt waste water produced by the factory in the raw material storage tank 1. When the evaporation operation starts, start the feed pump 2. At this time, the circulation pump 10 is in a closed state, and the high-salt waste water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com