Mixed working fluid power system with incremental vapor generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

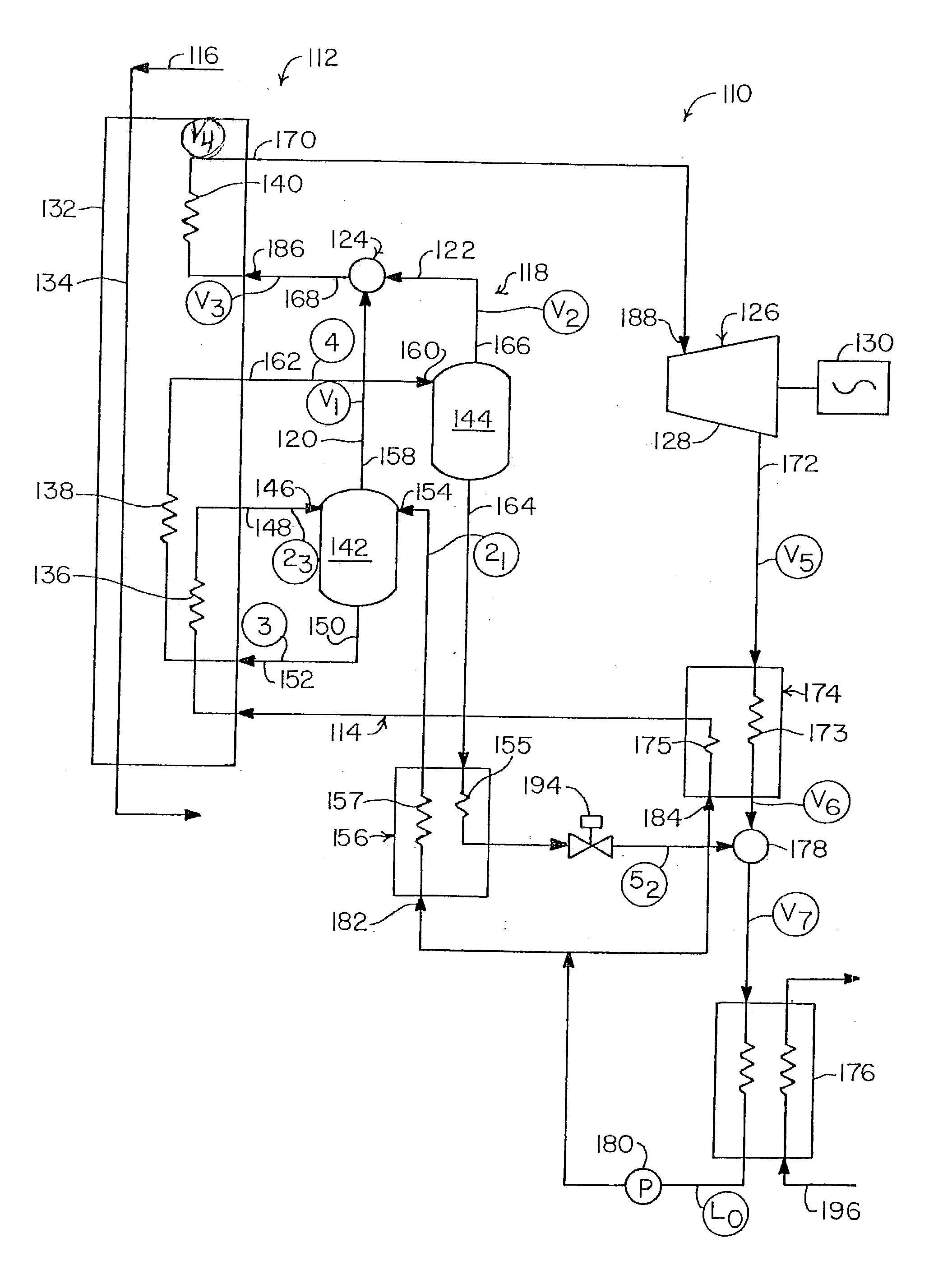

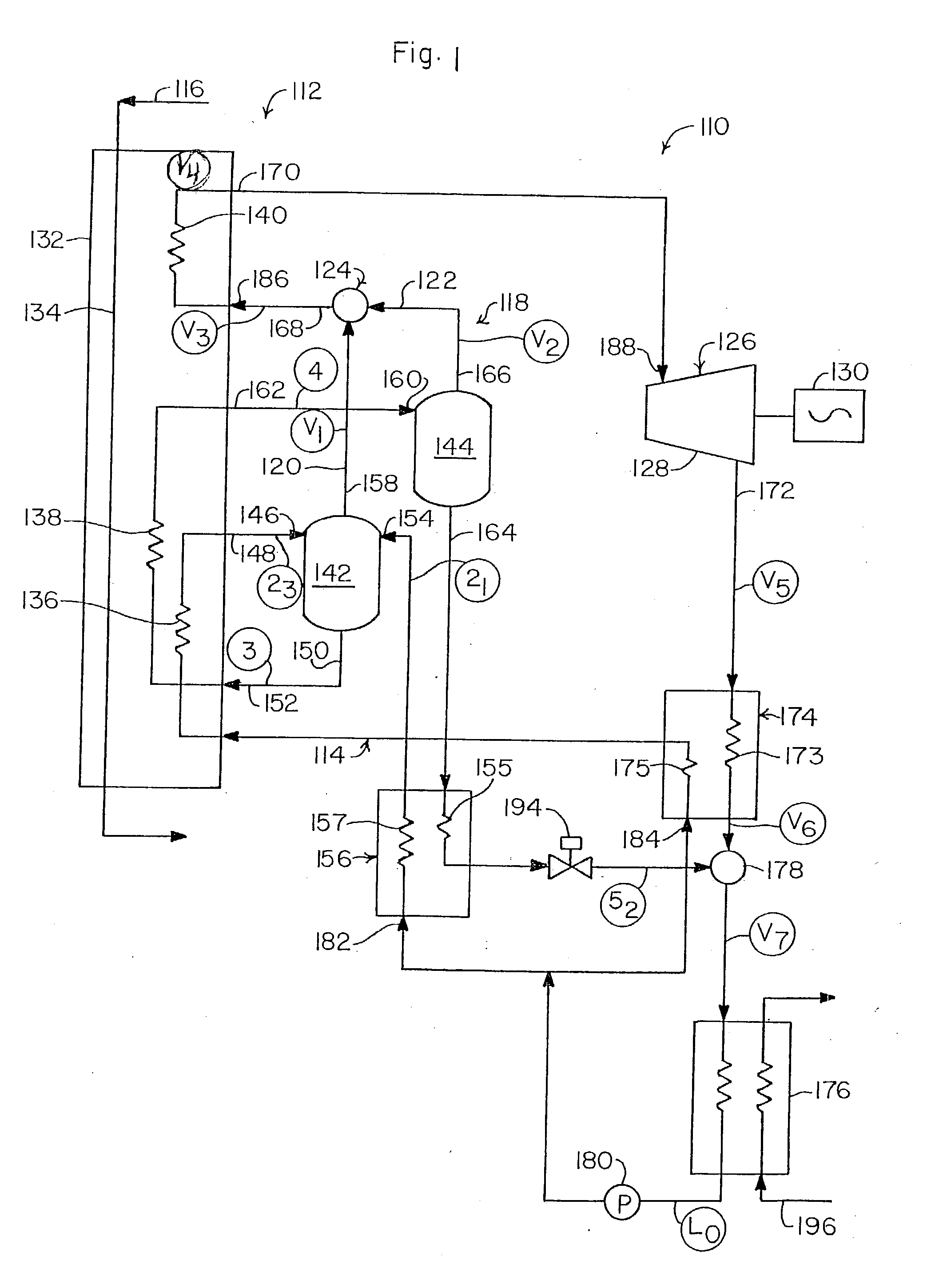

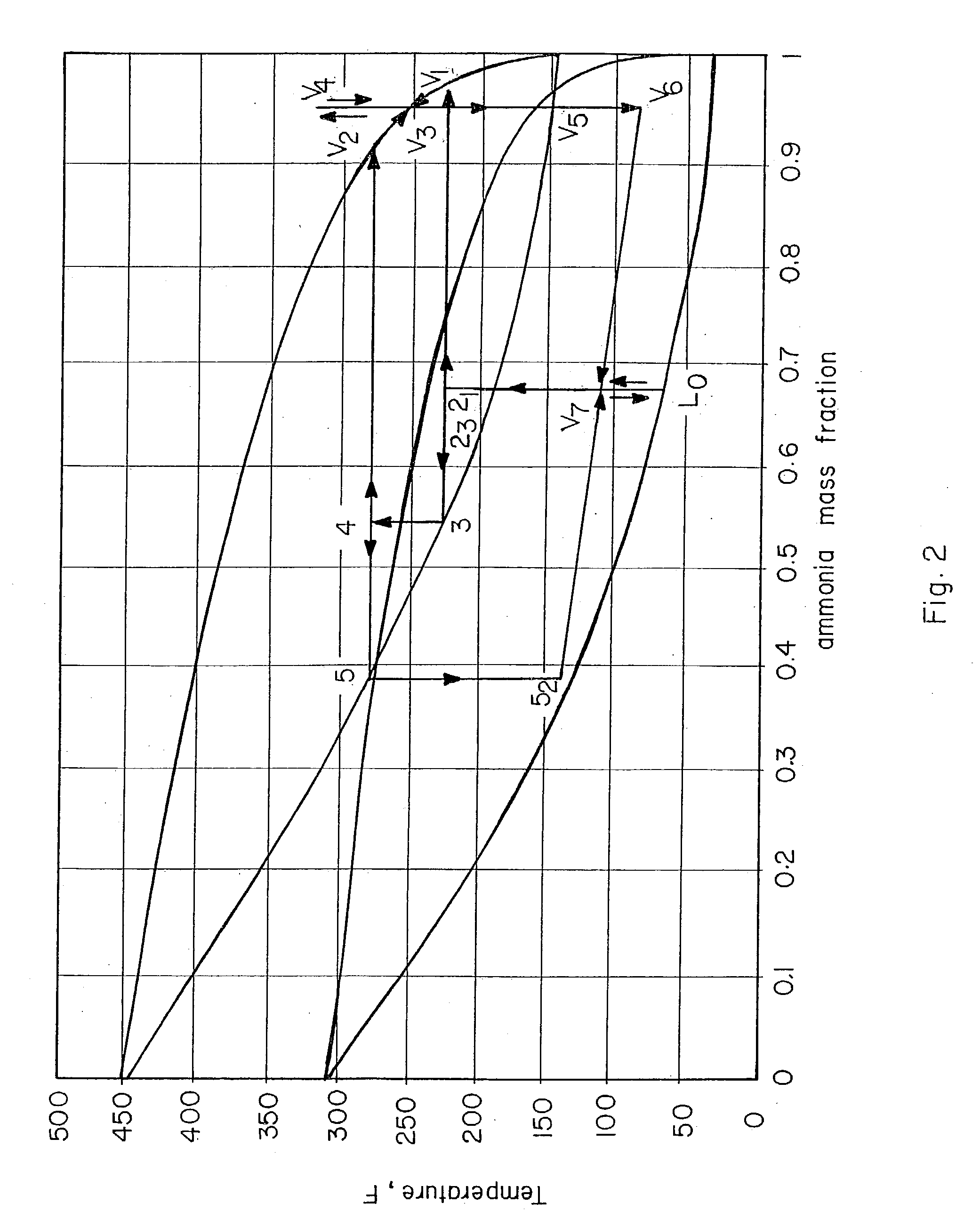

[0017] A power generating system 110 according to one embodiment of the present invention is shown in FIG. 1 and may comprise an incremental vapor generator system 112 for vaporizing a mixed working fluid 114. The incremental vapor generator system 112 incrementally vaporizes the mixed working fluid 114 with heat energy extracted from a heat source, such as, for example, geothermal brine 116. Alternatively, and as will be described in greater detail below, the present invention may be utilized with other types of heat sources and / or other types of heating fluids.

[0018] In the embodiment shown in FIG. 1, the incremental vapor generator system 112 comprises a parallel flow incremental vapor generation system 118 in which the mixed working fluid 114 is incrementally vaporized to form a first vapor portion 120 and a second vapor portion 122. The first and second vapor portions 120 and 122 thereafter may be combined in a vapor mixer 124 before being directed to an energy conversion syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com