Middle-set type high density sediment water purification tank and purification technology thereof

A high-density, water purification technology, used in flocculation/sedimentation water/sewage treatment, energy and wastewater treatment, etc., can solve the problems of difficult control of sludge discharge, complex civil structure, affecting effluent quality, etc. The effect of convenient construction and speeding up the separation of mud and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

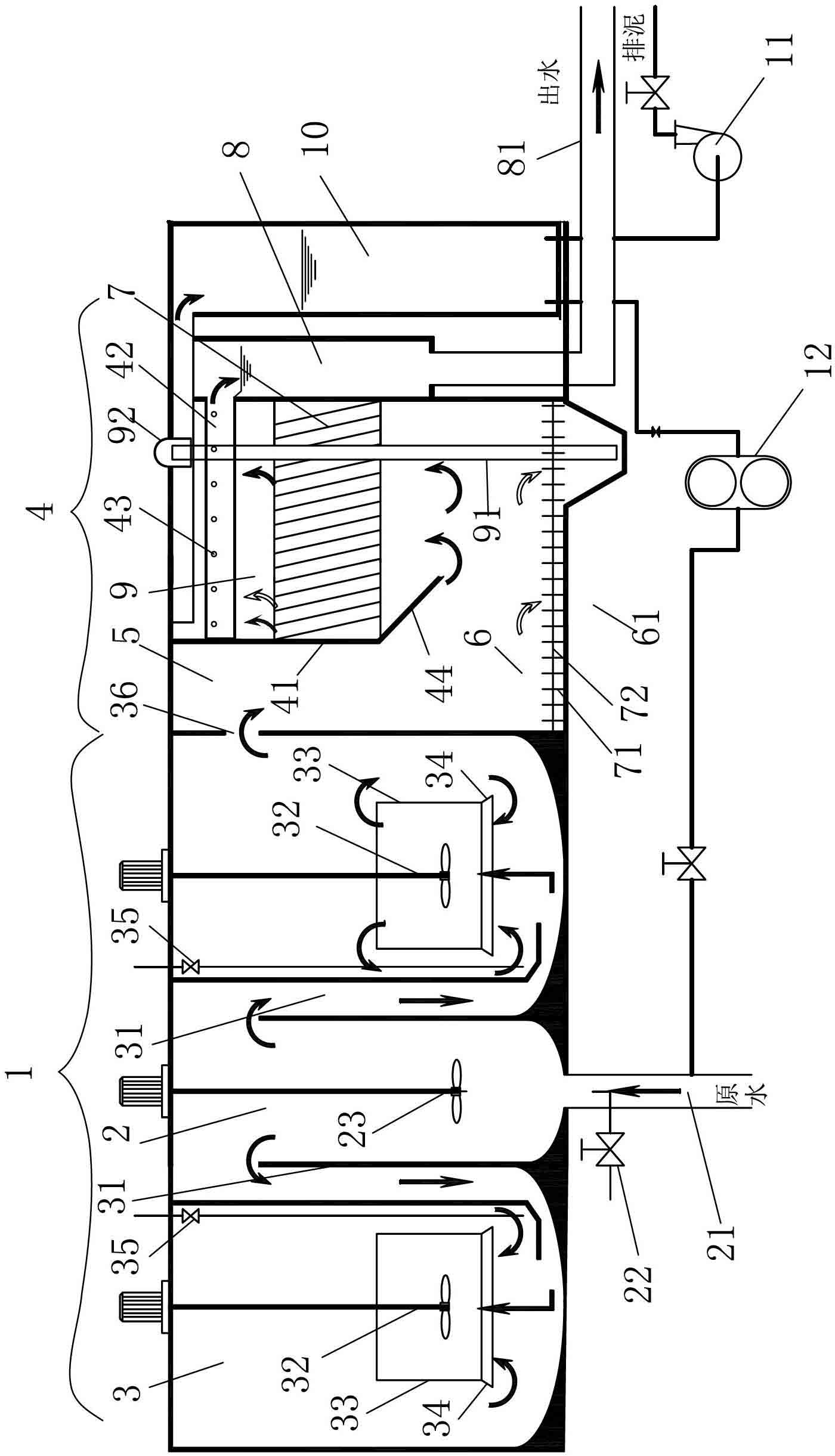

[0026] The mid-mounted high-density sedimentation water purification tank in the present invention mainly includes three major areas, a reaction area 1 , a clarification area 4 , and a sludge transfer tank 10 . The reaction zone 1 is mainly the stage of water intake, feeding, and full mixing. The clarification zone 4 is the stage of sedimentation, separation and purification of water, and finally the sludge and clean water are separated and discharged. All pool types involved in the present invention are arranged side by side in a rectangular structure, and the pool type structures are compact in layout.

[0027] The reaction zone 1 includes a mixing tank 2 and a flocculation tank 3 in the order of water inflow. The bottom of the mixing tank 2 is provided with a water inlet pipe 21, and a flocculant dosing pipe 22 is arranged on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com