Novel indoor air purification device

A technology for indoor air and purification devices, which is applied in combination devices, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of ozone generation, high manufacturing costs, and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

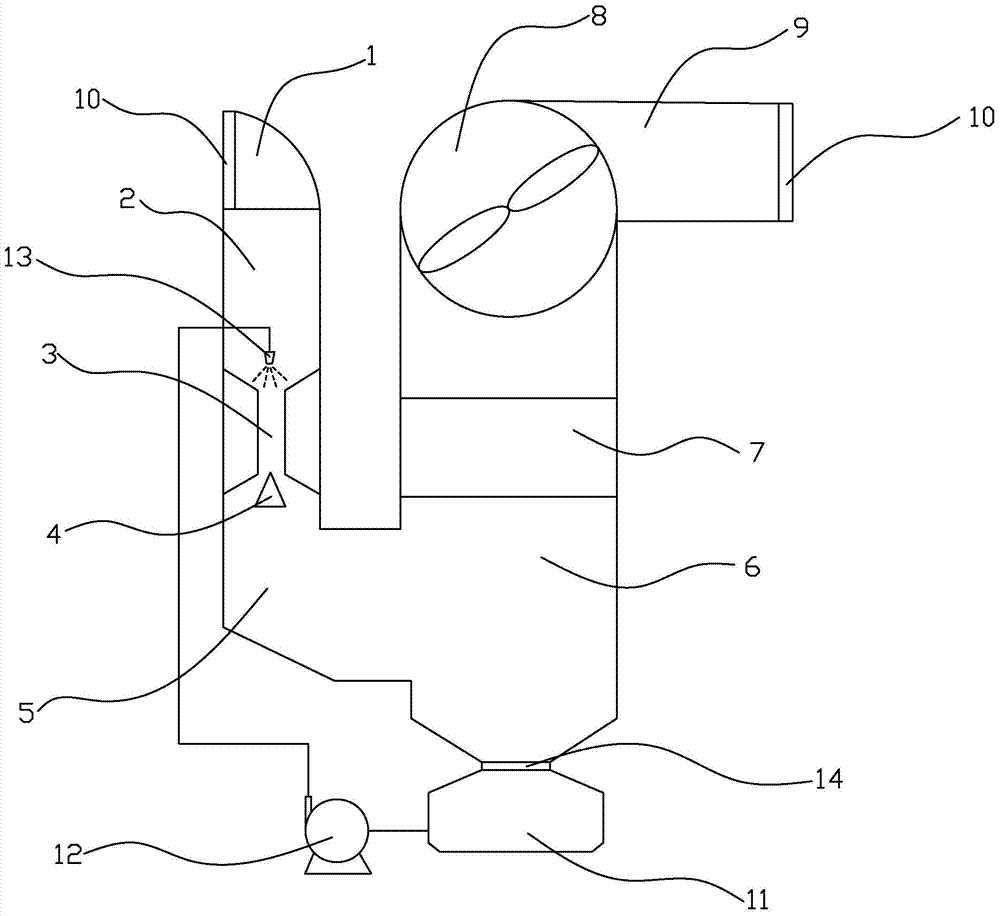

[0041] Combine below figure 1 The basic working procedure of the embodiment of the present invention is further described. The polluted air enters from the air inlet 1, and then enters the water inlet chamber 2. In the water inlet chamber 2, there is a circulating washing liquid nozzle 13, and the washing liquid pumped in from the liquid storage tank 11 is evenly distributed to the Venturi throat through the nozzle 13. On mouth 3, air and washing liquid enter Venturi throat 3 together, and the speed of air in Venturi throat 3 reaches more than 30 m / s, affected by the boundary of Venturi throat 3, the air in Venturi throat 3 A high velocity gradient is formed in the airflow, which generates extremely high shear force, and disperses the washing liquid entering the throat into uniform and fine water droplets. The damper 4 arranged at the outlet of the Venturi throat or inside is used to adjust the size of the air passage of the Venturi throat 3. After leaving the Venturi throat ...

Embodiment 2

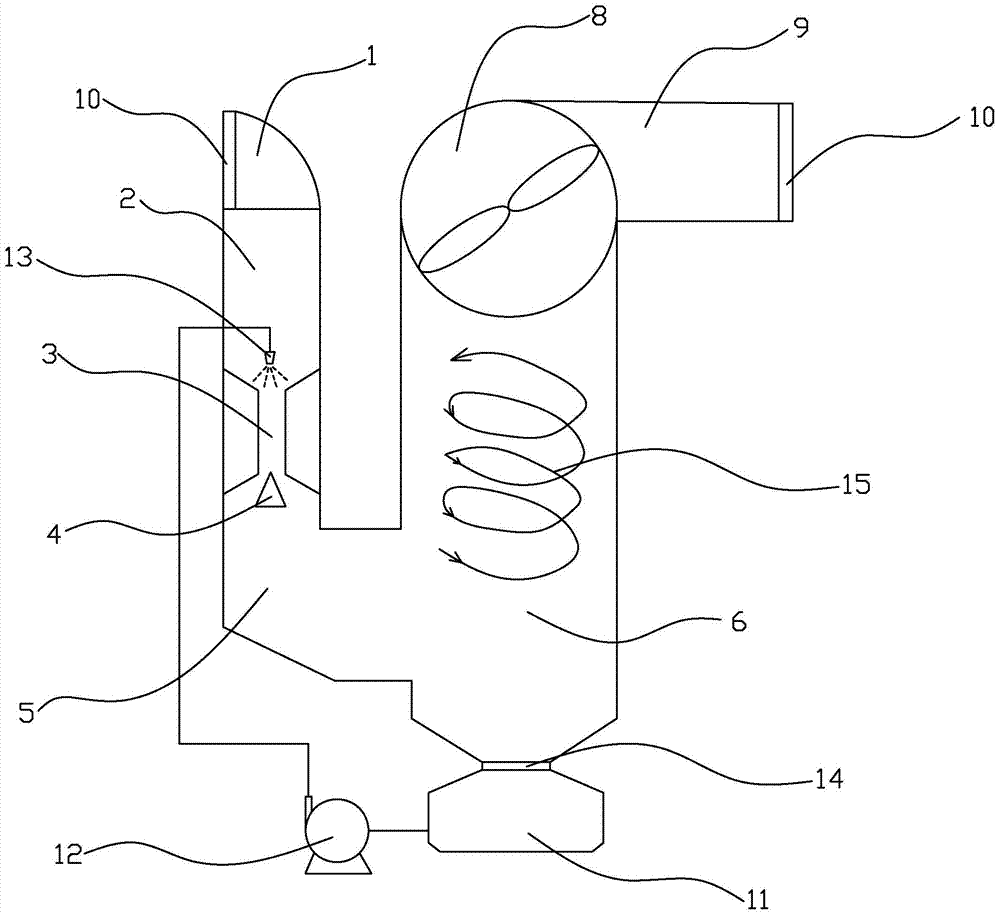

[0044] In embodiment two, the main body of the device is basically the same as embodiment one, the difference is that the gas-liquid separation adopts the cyclone separator 15 to carry out gas-water separation, and the droplets of the cyclone separator 15 entering the gas-liquid separation chamber 6 are subject to centrifugal force It acts as a centrifugal motion, and finally collides with the inner wall of the cyclone separator to leave the air. The dehydrated clean air passes through the fan 8 and enters the air outlet 9, and then enters the room again.

[0045] The purification effect on indoor air is shown in Table 1 and Table 2. The concentrations of PM2.5 particles and large particles in the indoor air before entering the device are 327 and 9 μg / m3 respectively 3 . SO 2 The concentration is 200μg / m 3 , the formaldehyde concentration is 300μg / m 3 .

[0046] Table 1

[0047]

[0048] Table 2

[0049]

Embodiment 3

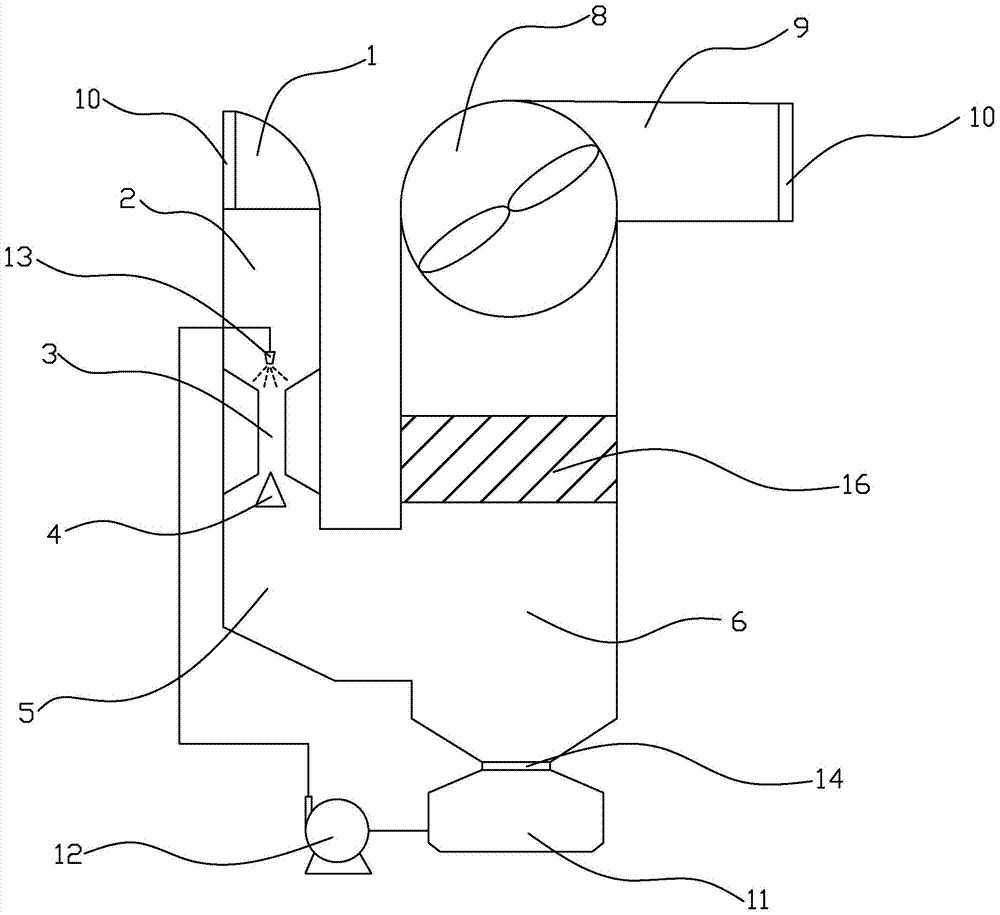

[0051] In embodiment three, the main body of the device is basically the same as embodiment one, the difference is that gas-liquid separation adopts chemical adsorption layer 16 to carry out gas-water separation, and the gas-liquid mixture entering the gas-liquid separation chamber 6 enters in the chemical adsorption layer 16, moisture It is adsorbed on the surface of the chemical desiccant and leaves the air, and the dehydrated clean air passes through the fan 8 and enters the air outlet 9, and then enters the room again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com