Device and method for comprehensively treating acidic sulfate organic waste water based on biological desulfurization

A technology for comprehensive treatment of organic wastewater, applied in the field of environmental engineering, can solve the problems of sulfur oxidation phase failure, easy breeding of aerobic heterotrophic bacteria, etc., achieve the effect of releasing inhibition, reducing the amount of alkali input, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

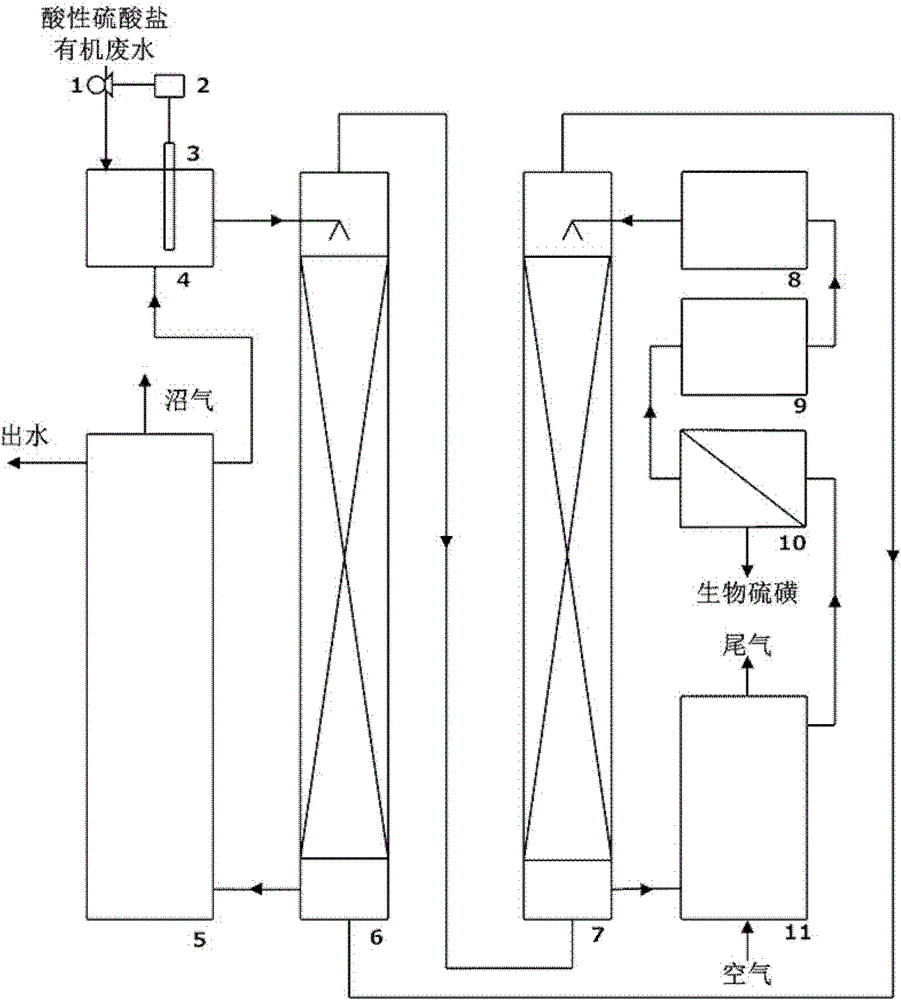

Method used

Image

Examples

Embodiment 1

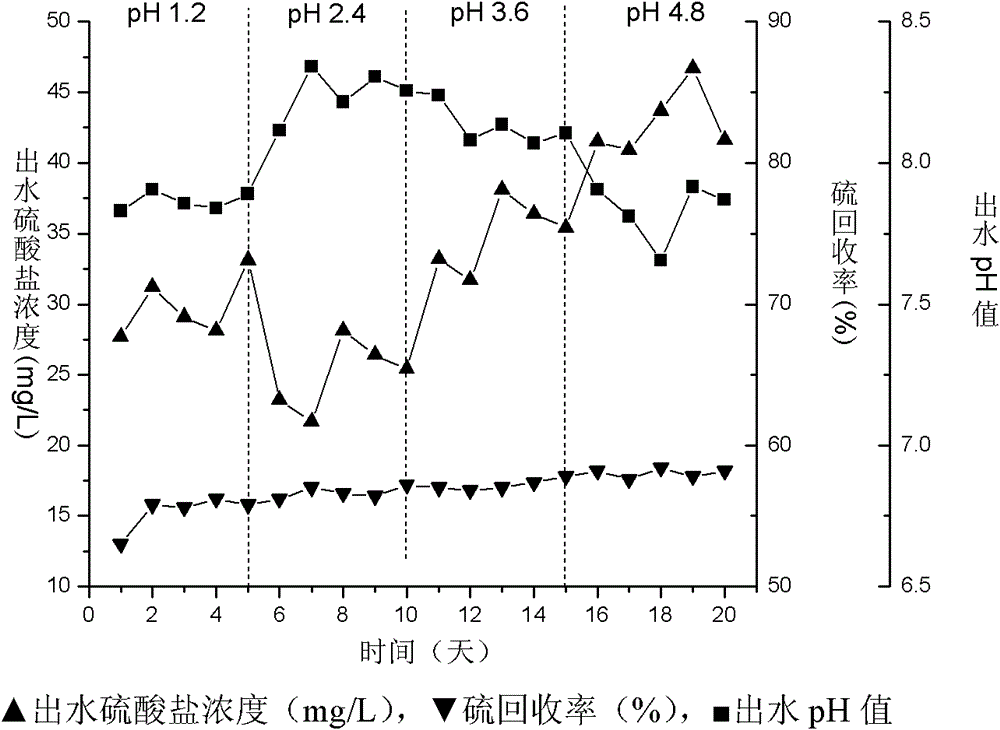

[0047] Embodiment 1 simulated acidic sulfate organic wastewater

[0048] Sodium lactate is used to simulate COD, the concentration is 10g / L, and other components in the simulated wastewater are (g / L): NH 4 Cl 1.0, KH 2 PO 4 1.0, MgCl 2 0.05, yeast extract powder 0.1, tryptone 0.1, CaCl 2 0.01, FeCl 3 0.01, MnSO 4 0.01, 1ml of 98% concentrated sulfuric acid, adjust the pH value to 1.2, 2.4, 3.6, 4.8.

[0049] The circulating gas between the gas stripping tower and the absorption tower is nitrogen.

[0050] In the sulfate reduction reactor, the methanogenic activated sludge circulated through the 100 mg / L sulfate culture solution contains sulfate reducing bacteria and methanogenic bacteria.

[0051] The sulfur oxidizing bacteria used in the sulfur oxidation reactor is Thiobacillus thioparus CGMCC 4826.

[0052] The circulating liquid between the hydrogen sulfide absorption tower and the sulfur oxidation reactor is (g / L): 0.1M Na 2 CO 3 / NaHCO 3 Buffer, pH 7.5-8.0.

...

Embodiment 2

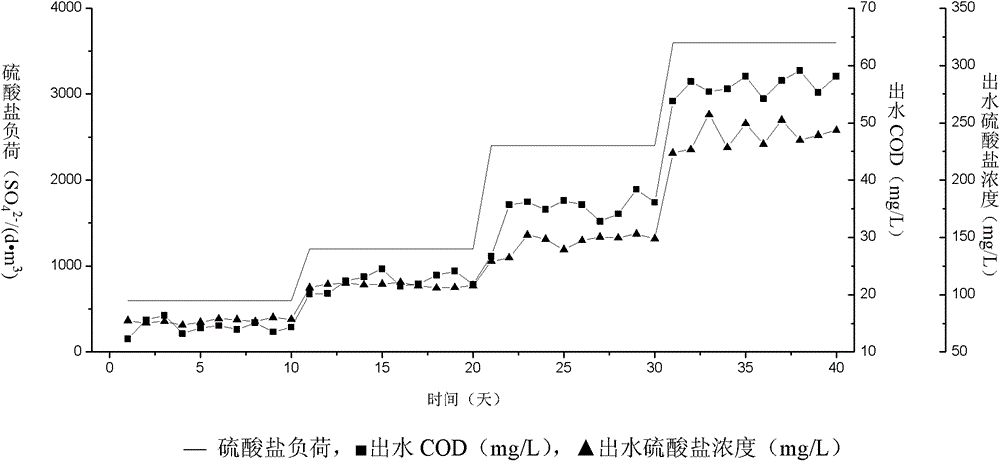

[0056] Example 2 dilute acid pretreatment straw organic wastewater treatment

[0057] Treat corn stalks with 1% (v / v) dilute sulfuric acid at 120° C. for 2 hours, wash with water 3 to 4 times, and use the treated stalks for cellulose enzymolysis. This dilute acid pretreatment process produces acidic sulfate organic wastewater. The COD of the wastewater is 2600mg / L, and the sulfate concentration is 1200mg / L.

[0058] Reactor loads of 600, 1200, 2400, 3600g SO 4 2- / (d·m 3).

[0059] The circulating gas between the gas stripping tower and the absorbing tower is methane.

[0060] In the sulfate reduction reactor, the methanogenic activated sludge circulated through the 100 mg / L sulfate culture solution contains sulfate reducing bacteria and methanogenic bacteria.

[0061] The sulfur oxidizing bacteria used in the sulfur oxidation reactor is Thiobacillus thioparus CGMCC 4826.

[0062] Wherein, the simulated wastewater flow rate is controlled to make the pH value of the mixe...

Embodiment 3

[0063] Embodiment 3 bisulfite process pulping wastewater treatment

[0064] The wastewater produced by bisulfite pulping has a COD value of 1200-1400mg / L and a sulfate concentration of 600-700mg / L.

[0065] The reactor load is 2400g SO 4 2- / (d·m 3 ).

[0066] Other operating methods and operations are the same as in Example 1. The final effluent sulfate content is not higher than 60.2-136.9mg / L, the sulfate removal rate is 90.2%-94.9%, and the COD value is 24.3-67.9mg / L. The biogas output is 0.02~0.03m 3 d -1 m -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com