Sol-gel method for preparing lithium titanate

A gel method, lithium titanate technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve problems affecting the quality of the sol, and achieve the effects of inhibiting hydrolysis, good control, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

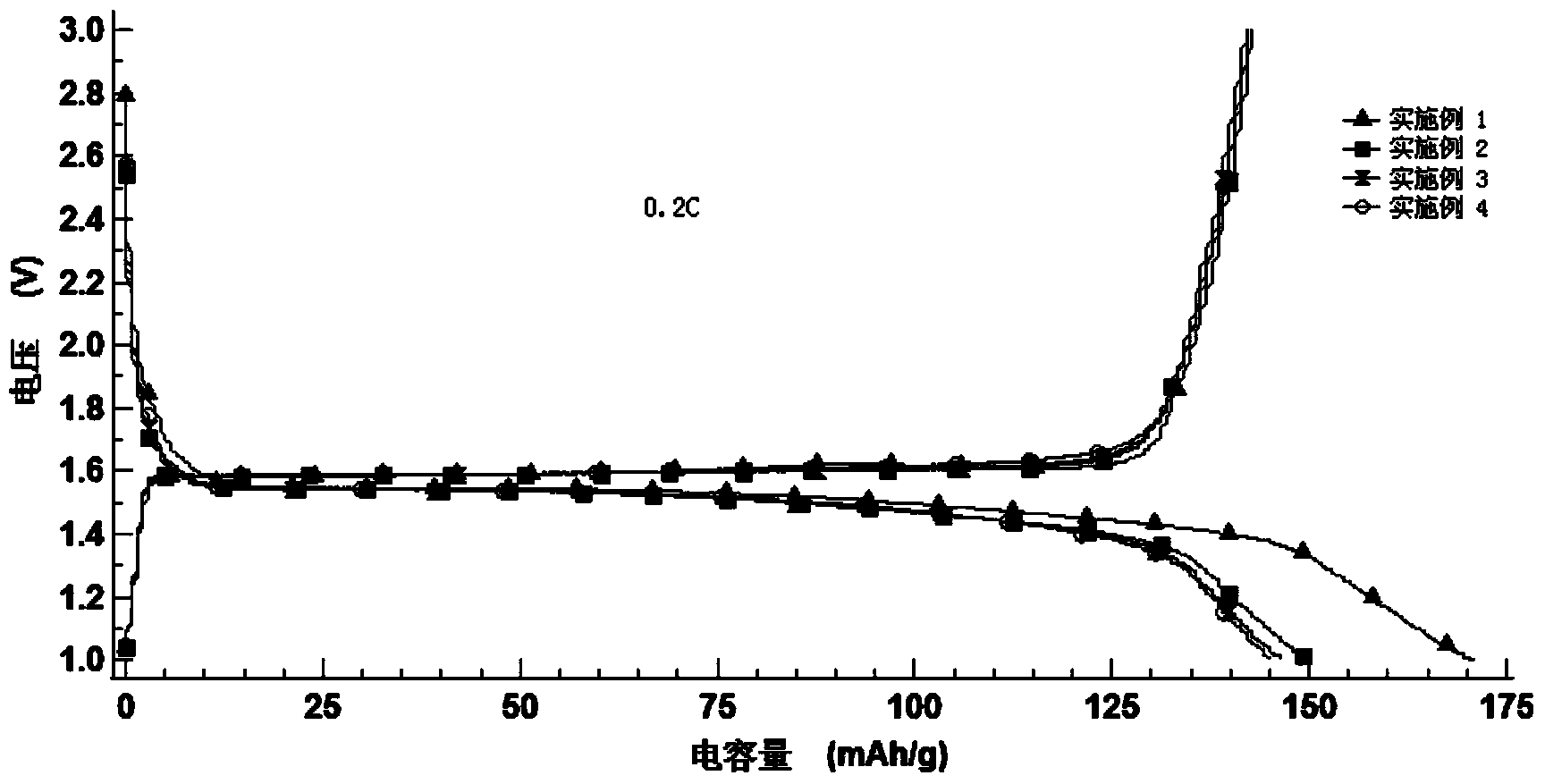

Embodiment 1

[0037] a. Dissolve 40mL of butyl titanate in 100mL of ethylene glycol to prepare M solution, stir rapidly to make it evenly mixed.

[0038] b. Mix 14.74g of lithium acetate dihydrate with 10mL of citric acid, 12mL of deionized water, and 80mL of absolute ethanol to prepare N solution.

[0039] c. Quickly stir the M solution, and at the same time, quickly drop the prepared N solution into the M solution at a speed of 0.25-0.3mL / s within 5 minutes, the pH value is 5.2, stir vigorously at room temperature for 30 minutes to obtain a transparent sol, and age After 24 hours, a milky white gel was obtained.

[0040] d. Put the gel obtained in step c into a drying oven, dry at a constant temperature of 80° C. for 36 hours to obtain a dry gel, and obtain a precursor after ball milling.

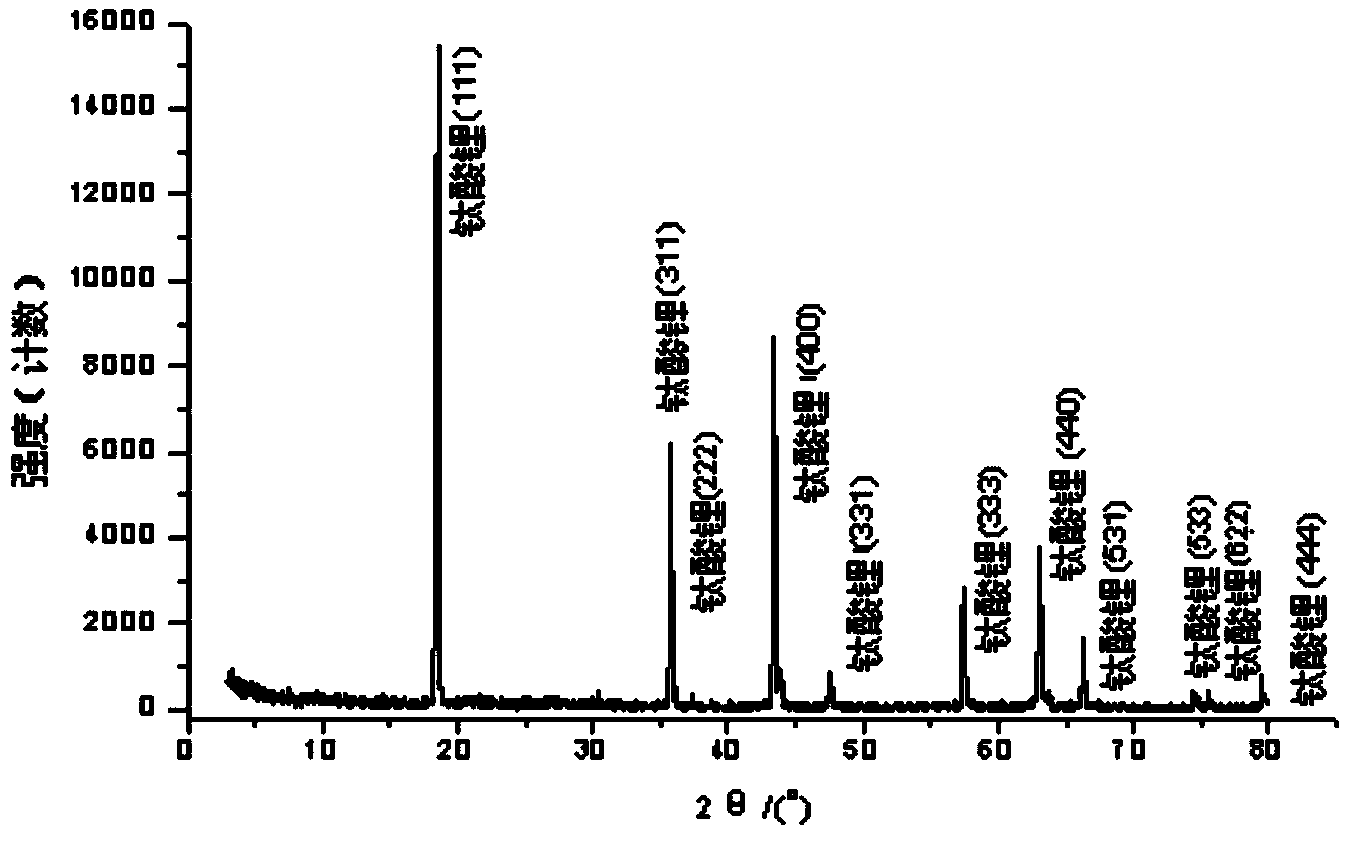

[0041] e. After fully grinding the precursor, use the segmental sintering method: at a heating rate of 5 °C / min, raise the temperature to 600 °C for 6 hours, cool to room temperature and fully grind f...

Embodiment 2

[0046] a. Dissolve 40mL of butyl titanate in 150mL of ethylene glycol to prepare M liquid, stir rapidly to make it evenly mixed.

[0047] b. Mix 14.74g of lithium acetate dihydrate with 10mL of citric acid, 20mL of deionized water, and 120mL of absolute ethanol to prepare N solution.

[0048] c. Quickly stir the M solution, and at the same time, quickly drop the prepared N solution 0.3-0.4mL / s into the M solution within 7 minutes, control the pH value to 5.7, stir vigorously at room temperature for 40 minutes to obtain a transparent sol, and age for 36 hours to obtain Milky white gel.

[0049] d. Put the gel obtained in step c into a drying oven, dry at a constant temperature of 80° C. for 36 hours to obtain a dry gel, and obtain a precursor after ball milling.

[0050] e. After fully grinding the precursor, use the segmented sintering method: at a heating rate of 5 °C / min, raise the temperature to 600 °C for 6 hours, cool to room temperature and fully grind for 0.5 h; then r...

Embodiment 3

[0053] a. Dissolve 40mL of butyl titanate in 80mL of ethylene glycol to prepare M liquid, stir rapidly to make it evenly mixed.

[0054] b. Mix 15.08g of lithium acetate dihydrate with 10mL of citric acid, 12mL of deionized water, and 80mL of absolute ethanol to prepare N solution.

[0055] c. Quickly stir the M solution, and at the same time, quickly drop the prepared N solution into the M solution at 0.25-0.3mL / s within 5 minutes, the pH value is 5.5, stir vigorously at room temperature for 30 minutes to obtain a transparent sol, and age for 24 hours to obtain Milky white gel.

[0056] d. Put the gel obtained in step c into a drying oven, dry at a constant temperature of 120° C. for 24 hours to obtain a dry gel, and obtain a precursor after ball milling.

[0057] e. After fully grinding the precursor, use the segmental sintering method: at a heating rate of 5 °C / min, raise the temperature to 600 °C for 12 hours, cool to room temperature and fully grind for 0.5 h; then raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com