Water-repellent polyolefin elastic fabric

A technology of elastic fabrics and polyolefins, which is applied in the direction of textiles and papermaking, and can solve problems such as poor adhesion, poor mechanical strength, and insufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A water-repellent polyolefin elastic fabric, comprising a polyolefin elastic fabric base material and a silicone water-repellent coating agent adhesive film arranged on the surface of the base material;

[0051] In terms of parts by mass, mix 10 parts of silicone water-repellent finishing agent, 4 parts of polyacrylic acid thickener, and 86 parts of water, and fully stir to form a silicone water-repellent coating agent. The viscosity reaches 35000-40000CPS. 2 Apply the coating agent on the polyolefin elastic fabric base material, then dry at 70°C for 5 minutes, and bake at 160°C for 2 minutes. The silicone water-repellent coating agent forms a film on the surface of the fabric, and the product The water-repellent polyolefin elastic fabric described above;

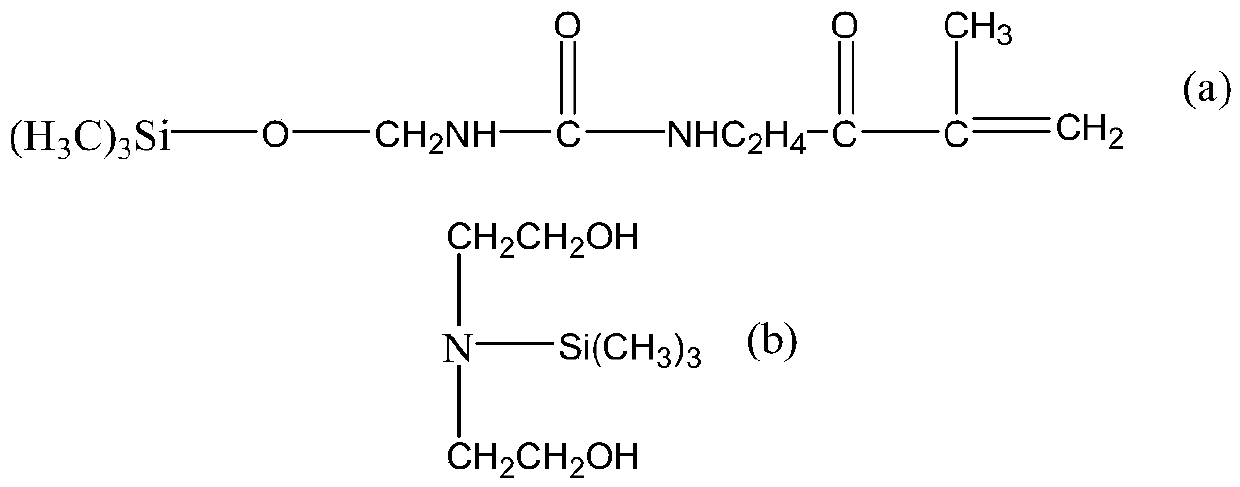

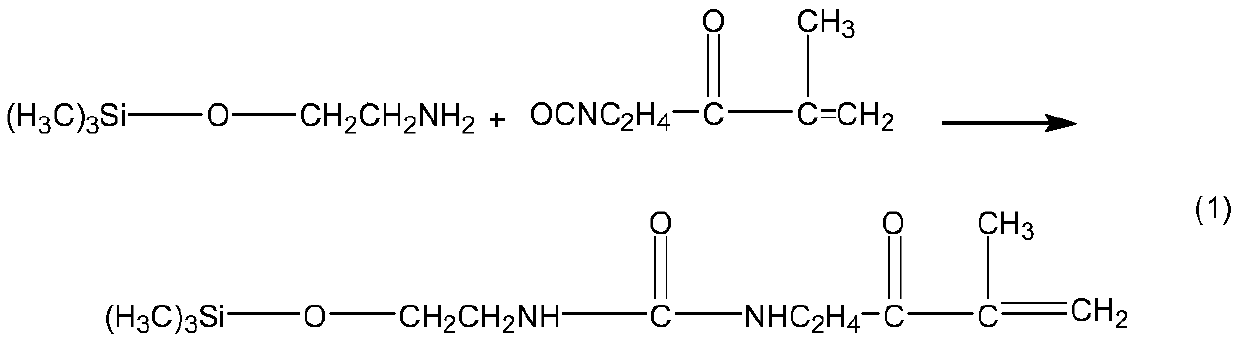

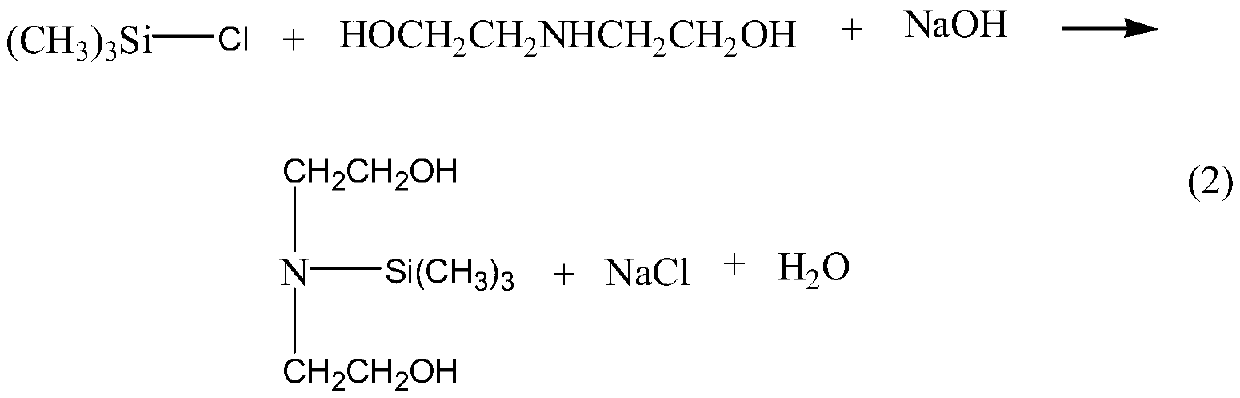

[0052] The silicone water-repellent finishing agent is formed by blending a silicone-modified acrylate emulsion and a silicone-modified polyurethane emulsion; the mass ratio of the silicone-modified acrylate emulsion...

Embodiment 2

[0066] A water-repellent polyolefin elastic fabric, comprising a polyolefin elastic fabric base material and a silicone water-repellent coating agent adhesive film arranged on the surface of the base material;

[0067] In terms of parts by mass, mix 10 parts of silicone water-repellent finishing agent, 4 parts of polyacrylic acid thickener, and 86 parts of water, and fully stir to form a silicone water-repellent coating agent. The viscosity reaches 35000-40000CPS. 2 Coating the silicone water-repellent coating agent on the polyolefin elastic fabric base material, then drying at 70°C for 5 minutes and 160°C for 2 minutes, the silicone water-repellent coating agent forms a film on the surface of the fabric , making the water-repellent polyolefin elastic fabric;

[0068] The silicone water-repellent finishing agent is formed by blending a silicone-modified acrylate emulsion and a silicone-modified polyurethane emulsion; the mass ratio of the silicone-modified acrylate emulsion to...

Embodiment 3

[0082] A water-repellent polyolefin elastic fabric, comprising a polyolefin elastic fabric base material and a silicone water-repellent coating agent adhesive film arranged on the surface of the base material;

[0083]In terms of parts by mass, mix 10 parts of silicone water-repellent finishing agent, 4 parts of polyacrylic acid thickener, and 86 parts of water, and fully stir to form a silicone water-repellent coating agent, with a viscosity of 35000-40000CPS. 2 Coating the silicone water-repellent coating agent on the polyolefin elastic fabric base material, then drying at 70°C for 5 minutes and 160°C for 2 minutes, the silicone water-repellent coating agent forms a film on the surface of the fabric , making the water-repellent polyolefin elastic fabric;

[0084] The silicone water-repellent finishing agent is formed by blending a silicone-modified acrylate emulsion and a silicone-modified polyurethane emulsion; the mass ratio of the silicone-modified acrylate emulsion to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com