Nano-organosiliconorganosilicon and polyurethane composite waterproof emulsion

A technology of nano-organic silicon and composite polyurethane, which is applied in the direction of liquid-repellent fibers, fiber types, textiles and papermaking, and can solve problems such as water resistance and insufficient mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

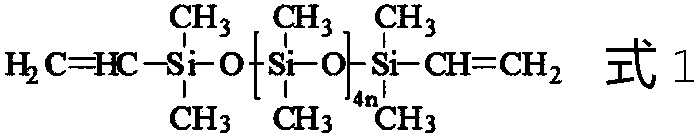

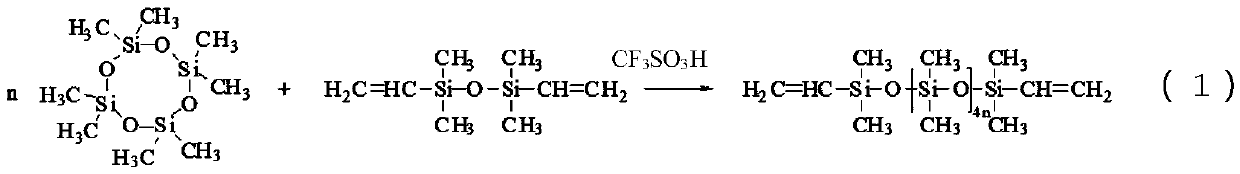

[0031] The preparation method of double-terminal alkenyl organosilicon monomer:

[0032] In a dry four-necked flask equipped with a thermometer and a stirrer, add a certain amount of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane and octamethylcyclotetrasiloxane , heated up to the reaction temperature while stirring, and added a certain amount of trifluoromethanesulfonic acid, and kept the temperature for a certain period of time. After the reaction, add anhydrous Na 2 CO 3 Stir and neutralize to pH 6-7, filter and distill the product under reduced pressure (90°C, vacuum degree below -0.1Mpa) to remove unreacted monomers to obtain a colorless and transparent liquid product. The reaction process involved is shown in (1).

[0033]

[0034] Monovinyl silicone monomer is prepared by reacting 2-(trimethylsiloxy)ethanolamine with allyl chloride. The preparation method is:

[0035] In a 250 mL three-necked flask, 1 mol of 2-(trimethylsiloxy)ethanolamine, 1.5 mol of triethylamine an...

Embodiment 1

[0042] A nano-organosilicon composite polyurethane waterproof emulsion, which is composed of nano-organosilicon emulsion and water-based polyurethane emulsion. In terms of mass percentage, the nano-organosilicon emulsion is 34% and the water-based polyurethane emulsion is 66%;

[0043] Described nano silicone emulsion is made of vinyl nano SiO 2 Sol, double-terminated alkenyl silicone monomer (as shown in formula 1), monovinyl silicone monomer (as shown in formula 2), emulsifier, water, and initiator are prepared by emulsion polymerization;

[0044]

[0045] (H 3 c) 3 Si—O—CH 2 CH 2 NH-CH 2 CH=CH 2 Formula 2

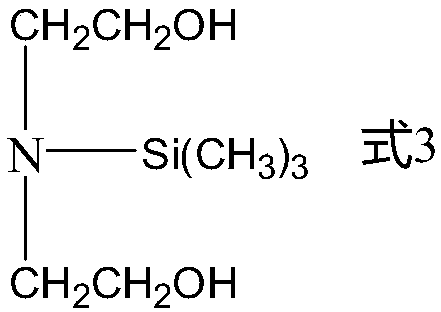

[0046] Described aqueous polyurethane emulsion is made of polyether glycol, diisocyanate, dimethylol propionic acid, dihydroxysilane monomer (as shown in formula 3), triethylamine, ethylenediamine, catalyst, organic solvent, water reaction made;

[0047]

[0048] The vinyl nano-SiO 2 Sol, made of vinyl silane coupling agent, catalyst, water, emulsifier, the...

Embodiment 2

[0061] A nano-organosilicon composite polyurethane waterproof emulsion, which is composed of nano-organosilicon emulsion and water-based polyurethane emulsion. In terms of mass percentage, the nano-organosilicon emulsion is 41% and the water-based polyurethane emulsion is 59%;

[0062] Described nano silicone emulsion is made of vinyl nano SiO 2 Sol, double-terminated alkenyl silicone monomer (as shown in formula 1), monovinyl silicone monomer (as shown in formula 2), emulsifier, water, and initiator are prepared by emulsion polymerization;

[0063]

[0064] (H 3 c) 3 Si-O-CH 2 CH 2 NH-CH 2 CH=CH 2 Formula 2

[0065] Described aqueous polyurethane emulsion is made of polyether glycol, diisocyanate, dimethylol propionic acid, dihydroxysilane monomer (as shown in formula 3), triethylamine, ethylenediamine, catalyst, organic solvent, water reaction made;

[0066]

[0067] The vinyl nano-SiO 2 Sol, made of vinyl silane coupling agent, catalyst, water, emulsifier, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com